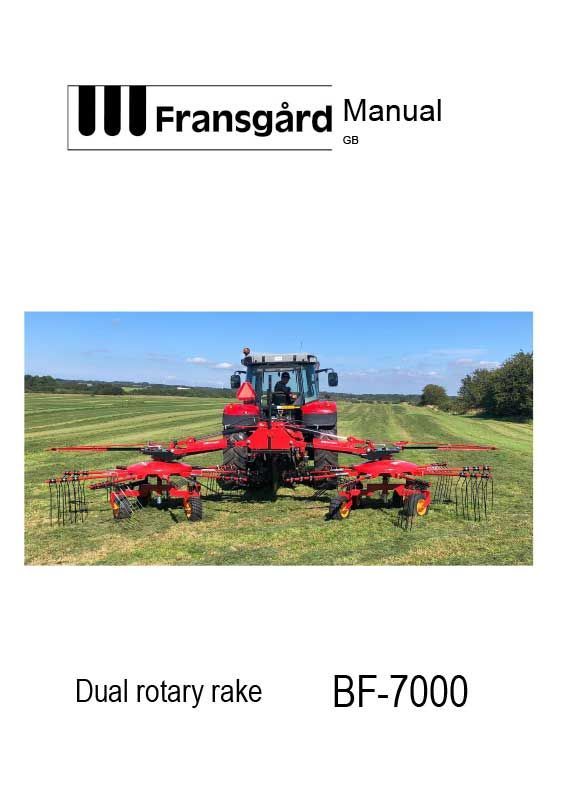

Rotorive BF-7000

Presentation

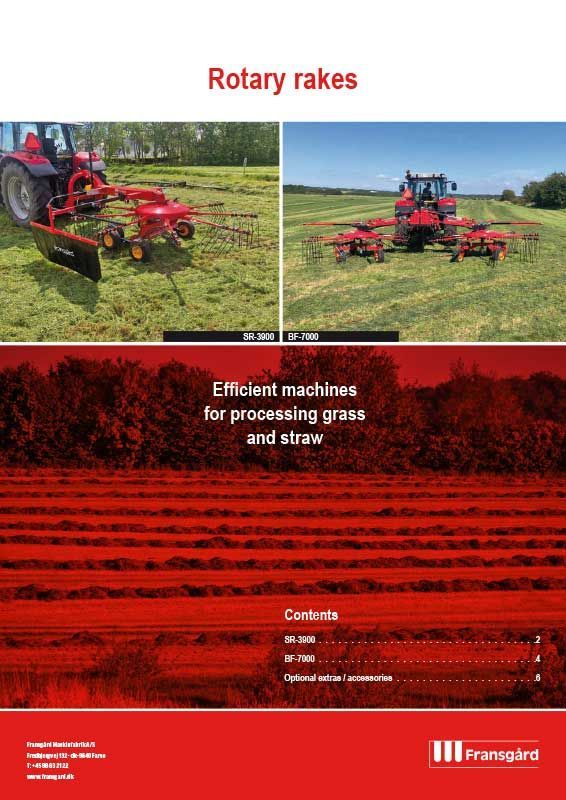

With a working width of 7 metres, the BF-7000 double rotary rake is a great alternative to a towed rake. The BF-7000 is used for grain, grass and hay in varying quantities. The machine has a large working width, yet is compact during transport.

The quick changeover from field work to short transport length increases efficiency. Therefore, it is ideal for the farmer with several smaller fields, as it is quick to fold and unfold, making it very flexible.

Efficient rotary rake that follows the terrain

The BF-7000 is built on 2 heavy-duty wheel suspensions. The Boogie system consists of 2 sets of 4 wheels each for a stable and smooth workflow. It has 4 large swivelling wheels and a flexible suspension under each rotor and together with the floating cylinders, it follows all terrains optimally.

The rotor is built on the same principle as our popular and proven TI models, consisting of an open curve control and nylon wheels, which makes it easy to service. Each rotor has a separate stepless height adjustment and is fitted with 9 arms with 3 rake springs each.

The machine has hydraulic folding/unfolding before and after transport. The transport option allows for a ground clearance of less than 4 metres and a width of 2.9 metres.

In brief: Compact, flexible and efficient.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Technical data:

| Model: | BF-7000 |

|---|---|

| Working width | 700 cm |

| Transport width | 290 cm |

| Raking arms per rotor | 9 pcs. |

| Double rake springs per raking arm | 3 pcs. |

| Rotor diameter | 323 cm |

| Number of wheels per rotor | 4 pcs. (16.5x6.5-8/6 ply) |

| Number of hydraulic sockets | 1 double-acting |

| Tractor requirement | 60 kW |

| 3-point linkage | Cat II |

| PTO rpm | max. 400 |

| Swath cover | Standard |

| PTO axle | Standard |

| Transport chain | Standard |

| Weight | 1.320 kg. |

Details

3-point

The solid 3-point suspension is rolled in square profile tube, which ensures high strength and good design.

Transport lock bracket

The heavy-duty bracket locks automatically when the machine is folded up in the transport position. Released mechanically with a pull cord.

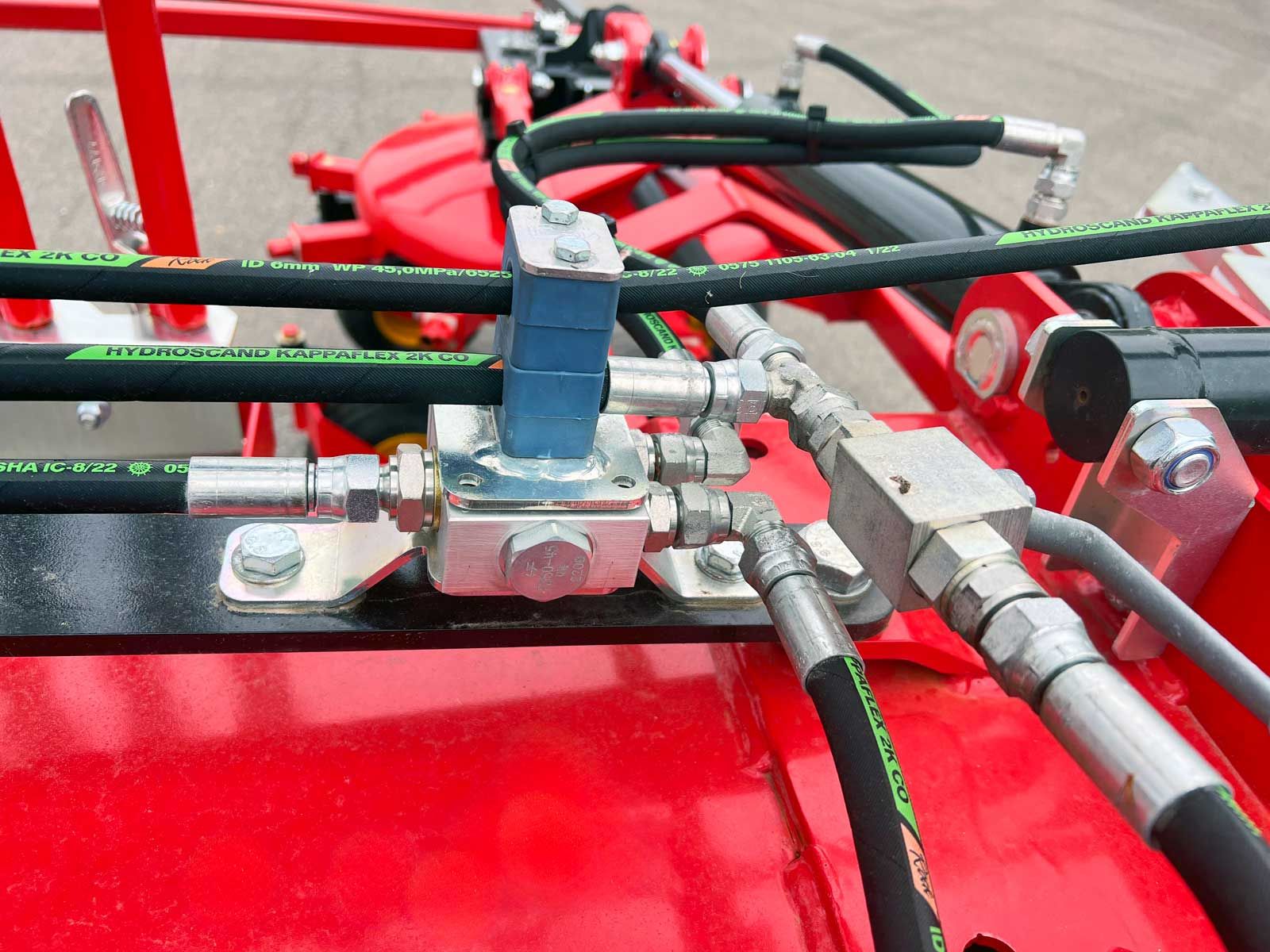

Flow divider

Hydraulic flow divider ensures that the machine follows the terrain optimally.

Galvanised bolts

Galvanised bolts with grease nipples ensure a long life.

Gearbox

The powerful T-gearbox is well protected in the main frame for optimised operation.

Yellow warning labels

The rake has obvious yellow warning labels.

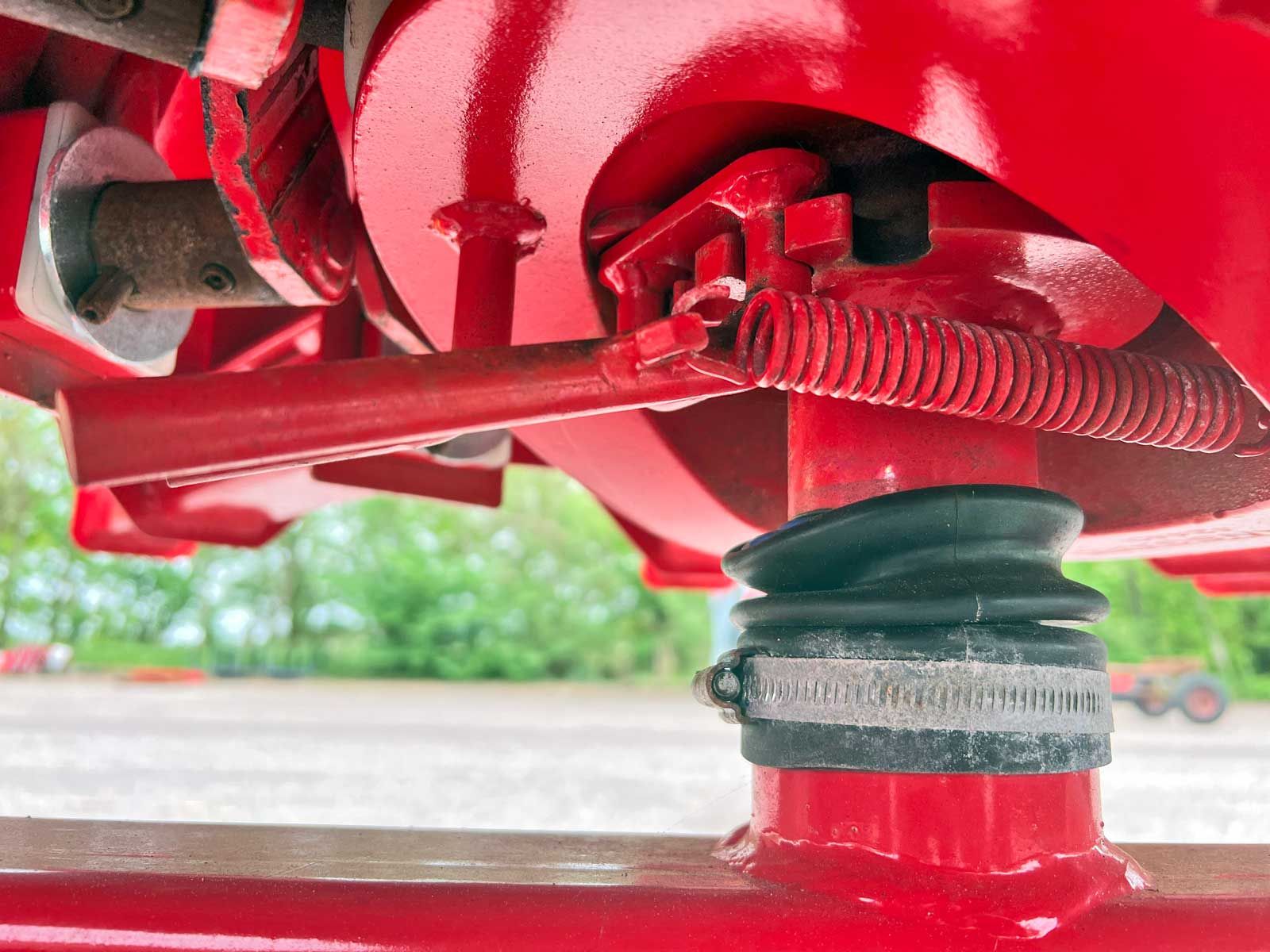

Rubber shielding

The rubber collar under each rotor protects the main shaft from dust, dirt, etc.

Wheels, close

Large solid wheels with greaseable hubs.

Wheels

4 swivelling wheels under each rotor.

Wheel frame

The wheel frame under each rotor tilts in pairs and the wheels are staggered for maximum bearing surface.

Holders for the raking arms

The raking arm is set in transport and winter storage position.

Main frame

The design of the heavy-duty main frame ensures a very stable machine.

Hydraulic cylinder, rotor

The double-acting hydraulic cylinder runs smoothly during operation to ensure an optimal workflow.

Hydraulic transport lock

Hydraulic operation of the transport lock: OPTIONAL EXTRA.

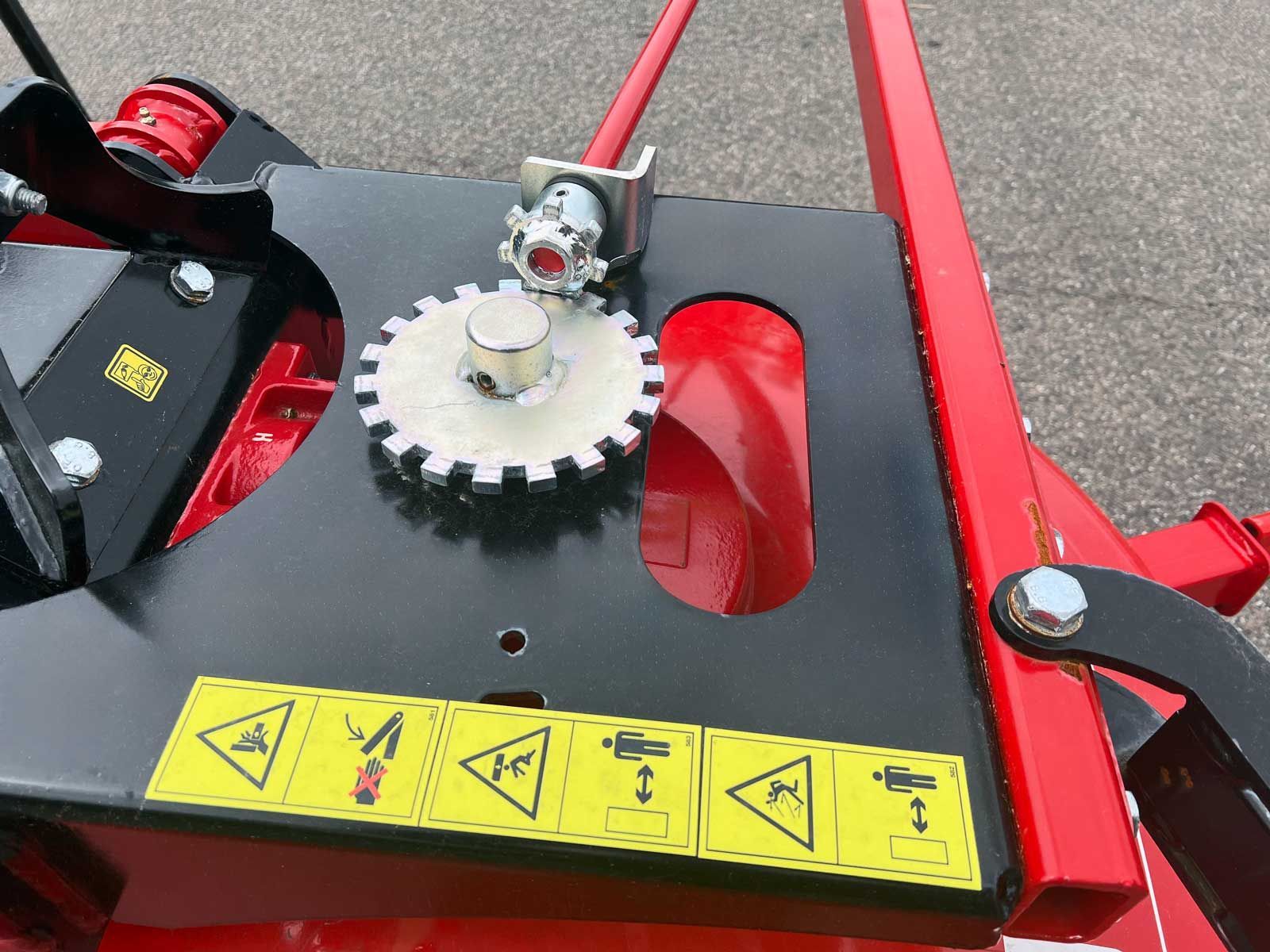

Handle for height adjustment

Galvanised handle with locking pawl is located outside the safety bars for easy access.

Adjusting the raking

The curve control can be adjusted in 3 positions to achieve the best possible result depending on the type of crop you are working with.

Crown drive pinion

The curve control can be adjusted in 3 positions to achieve the best possible result depending on the type of crop you are working with.

Curve control

The moulded curve control with nylon-wheels has ball bearings for a long life and is designed to be very easy to service.

PTO axle main boom

The PTO axle with spring-loaded coupling is well protected in the main frame.

PTO fittings

The powerful linkage to the PTO axles ensures an optimal angle of the PTO in the different settings and the best possible angle of the PTO to the tractor.

PTO hook

The powerful linkage to the PTO axles ensures an optimal angle of the PTO in the different settings and the best possible angle of the PTO to the tractor.

PTO rotor

Each rotor is driven by a powerful PTO shaft.

Raking arms

The powerful linkage to the PTO axle ensures an optimal angle of the PTO in the different settings and the best possible angle of the PTO to the tractor.

Rotor

The moulded rotor ensures a very robust and stable machine.

Safety bars

The safety bars can be folded to reduce the overall height.

Swath cover

Tarpaulin swath cover with plastic stiffeners that automatically flip up during transport.

Transport

The rake folds hydraulically for transporting.

Height adjustment

Galvanised cogwheel on top of the rotor for height adjustment of the desired rake height, separately for each rotor.

Raking arms

The raking arm is fitted with 3 rake springs via a special bracket, and the rake spring is bent to achieve maximum clearance when folding up.

Hose holder

As standard, the machine is fitted with a galvanised holder for hydraulic hoses to keep them off the ground.

Support leg, rear

Support legs with 2 feet at the rear of the machine ensure stable parking of the machine.

Support legs, front

2 angled support legs at the front of the machine ensure stable parking. If the machine is parked in the transport position, it must be on a firm, level surface.

Optional extras

Item No. 5600

Hydraulic cylinder for locking and releasing transport locks.

Ready for installation as standard.

Download PDF files

See our information material here, where you can also read it online, print or download the file.