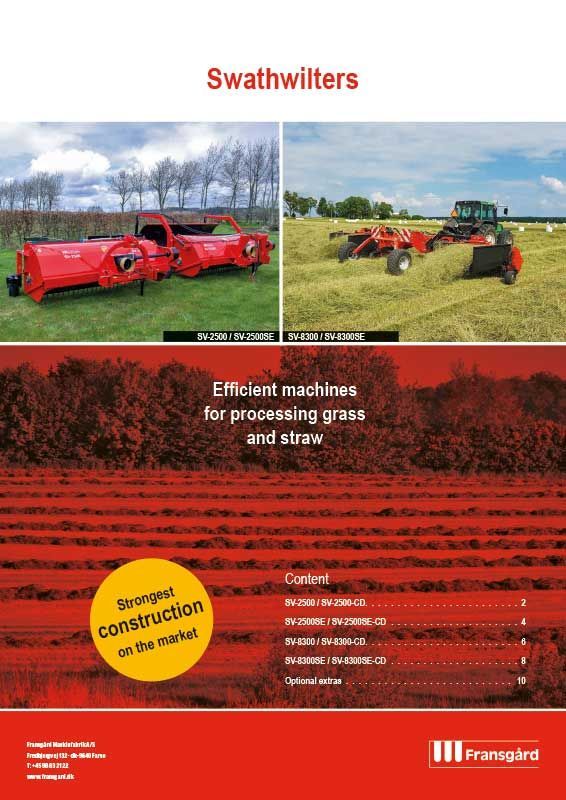

Swath Wilter SV-8300 / SV-8300-CD

Presentation

Fransgård's popular SV-2500 Swath Wilters are used as the basic construction in the dual-equipped SV-8300 / SV-8300-CD Swath Wilters. It is built in a strong construction with hydraulic folding, which makes it both efficient and flexible at the same time. The machine is a towed model designed to process 2 swaths simultaneously. Therefore, it expands the model range of Swath Wilters, making Fransgård the market leader in these machines.

The machine can be used with great advantage in grass, hay and straw, and leaves a high airy swath without impurities such as soil and stones.

In short: BETTER CROP QUALITY

Efficient swath wilter with multiple options

The SV-8300 / SV-8300-CD Swath Wilter has 2 powerful rotors, each fitted with 6 rows of springs and equally spaced around the shield for a uniform flow. The 2 x 4 V-belts ensure optimal non-stop operation.

The SV-8300-CD has the same basic design as the SV-8300, but with chain drives instead of v-belts.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Technical data:

| Model: | SV-8300 | SV-8300-CD |

|---|---|---|

| Working width | 760 - 830 cm | 760 - 830 cm |

| Transport width | 300 cm | 300 cm |

| Transport height | 400 cm | 400 cm |

| Transport length | 540 cm | 540 cm |

| Number of rotors | 2 | 2 |

| Rotor diameter | 80 cm | 80 cm |

| Rotor speed at 540 rpm | 485 rpm. | 485 rpm. |

| Number of rake springs | 144 | 144 |

| Number of wheels on the rotor | 4 | 4 |

| Number of transport wheels | 2 | 2 |

| Hydraulic connectors | 3 double | 3 double |

| PTO connector rpm | 400 – 540 | 400 – 540 |

| Power requirement kW/HP | Min. 40 kW | Min. 40 kW |

| Working speed km/h | 10-22 | 10-22 |

| Weight | 2860 kg | 2860 kg |

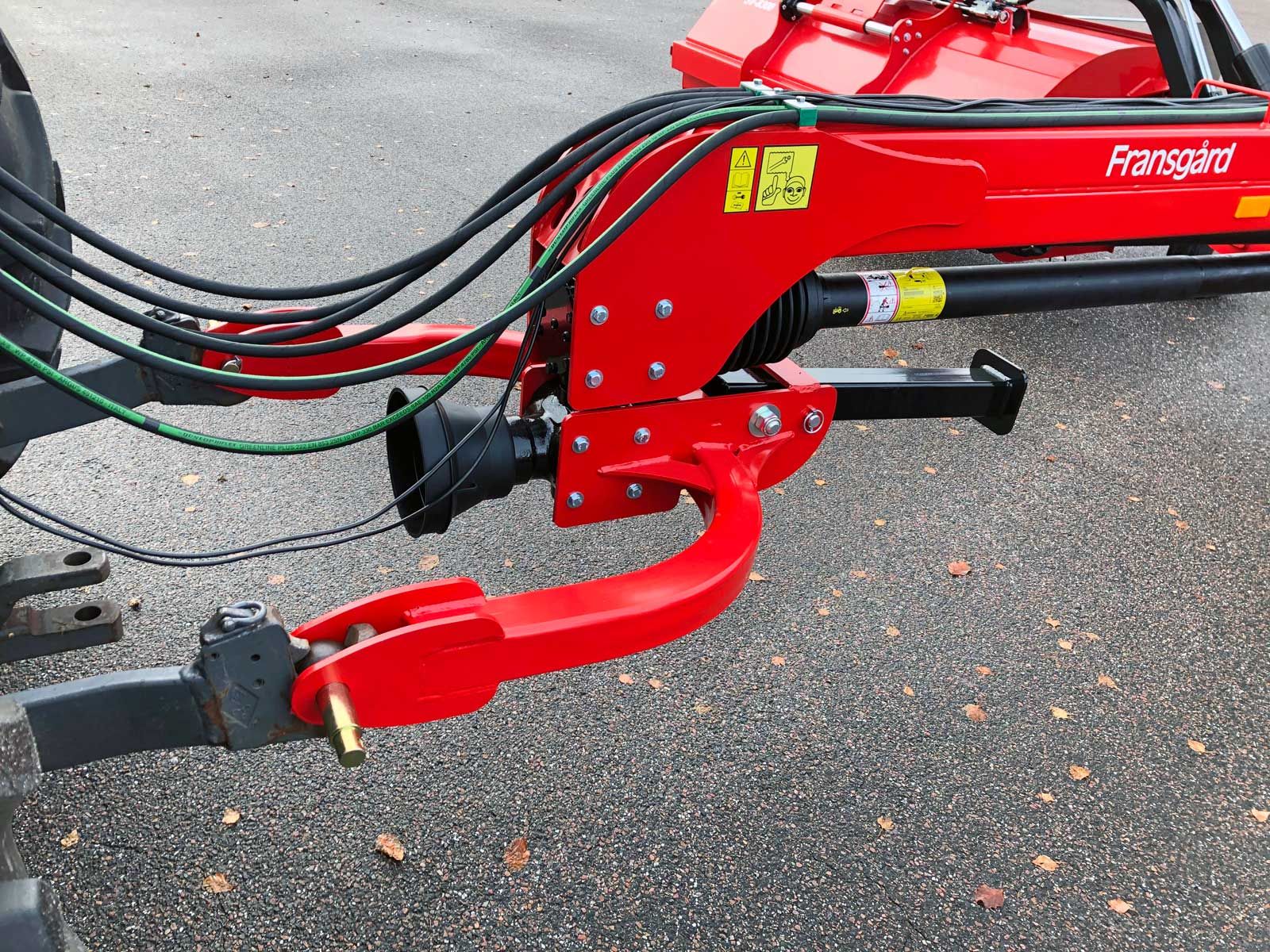

| Lift bracket | KAT II/III | KAT II/III |

Details

Fittings for swath guards

The large, heavy swath guards are mounted in a reinforced bracket with 2 bolts and nuts.

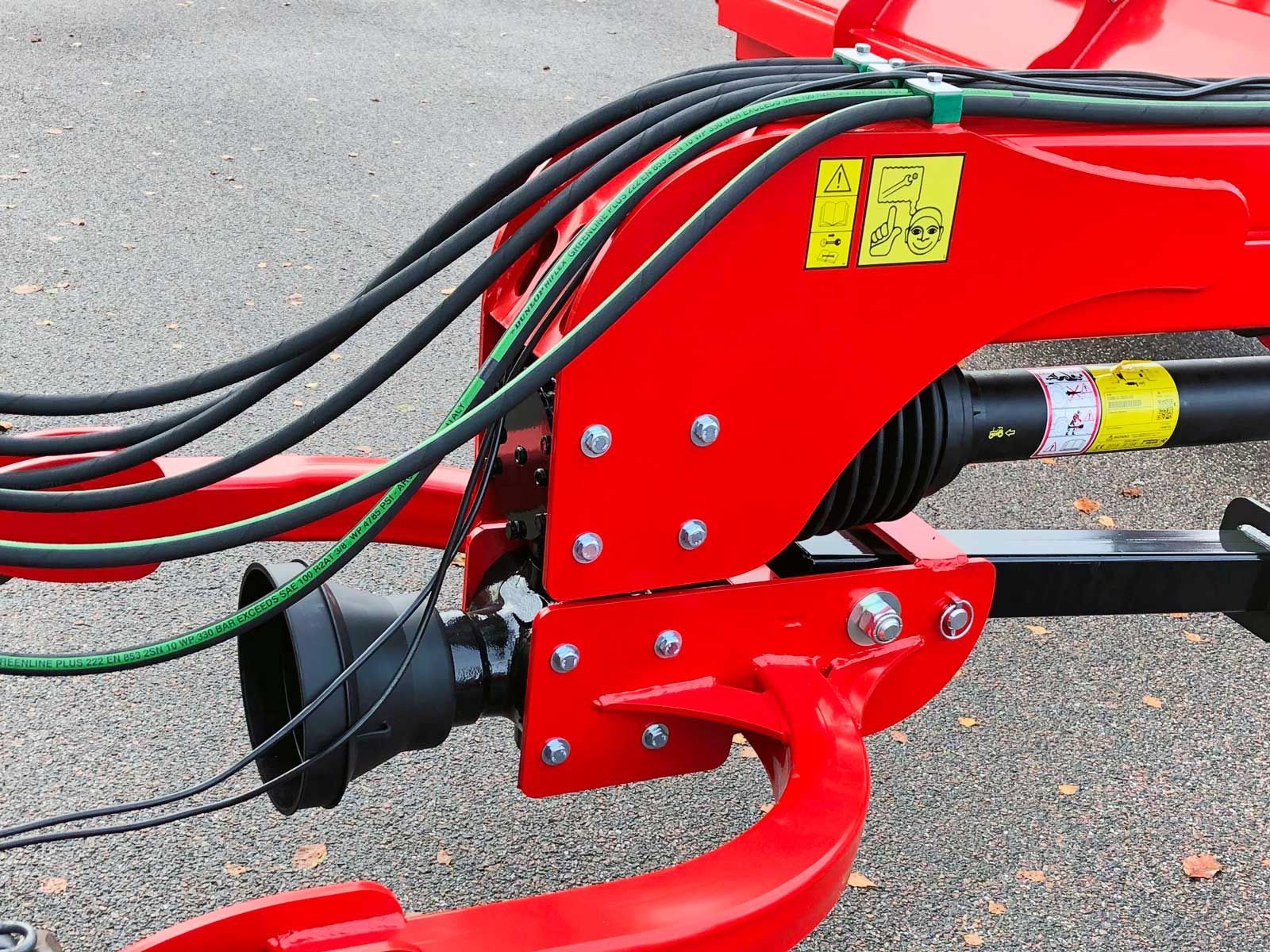

Drive shaft

PTO shaft gearbox and belt pulleys ensure optimal operation of the machine.

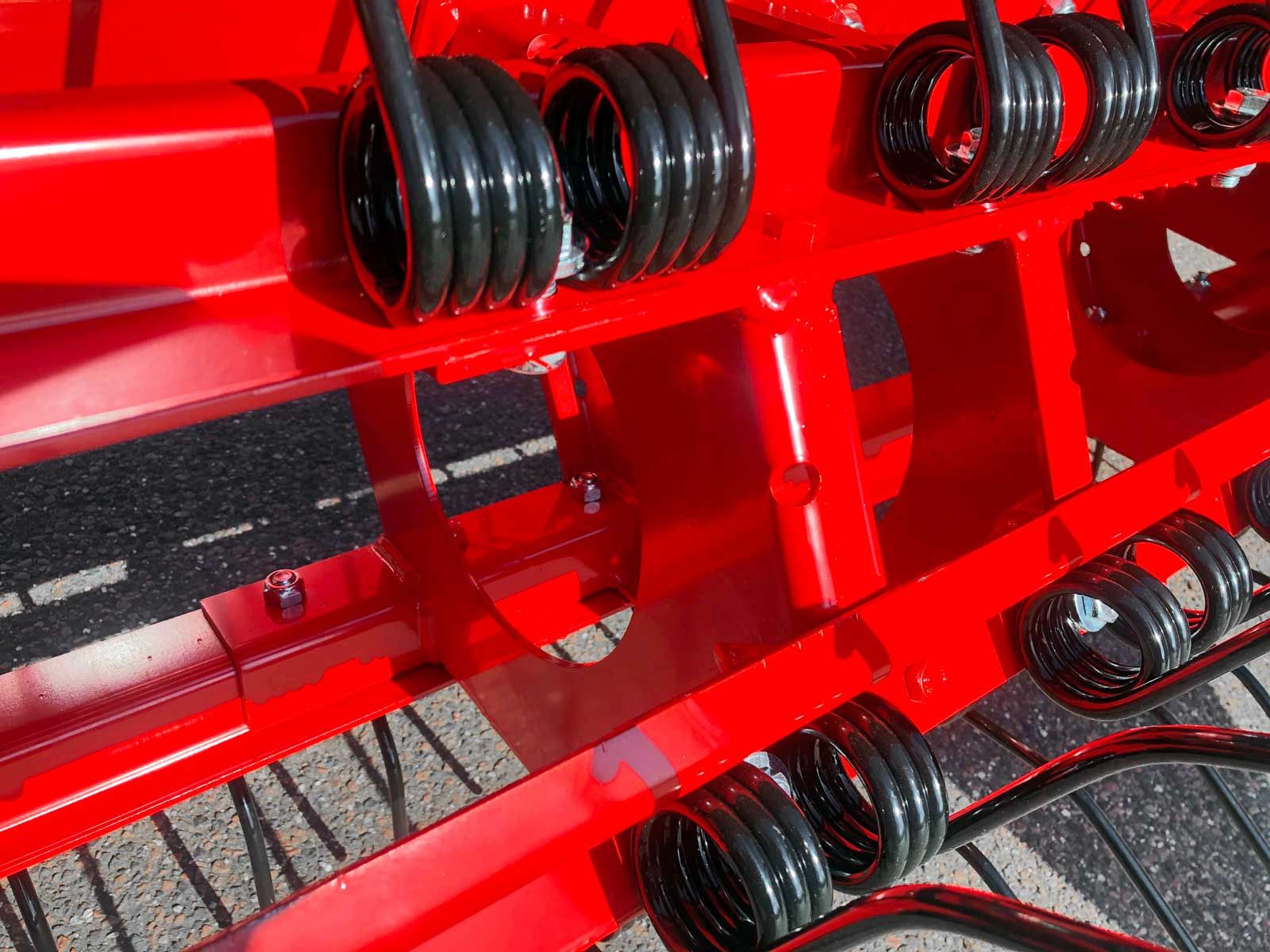

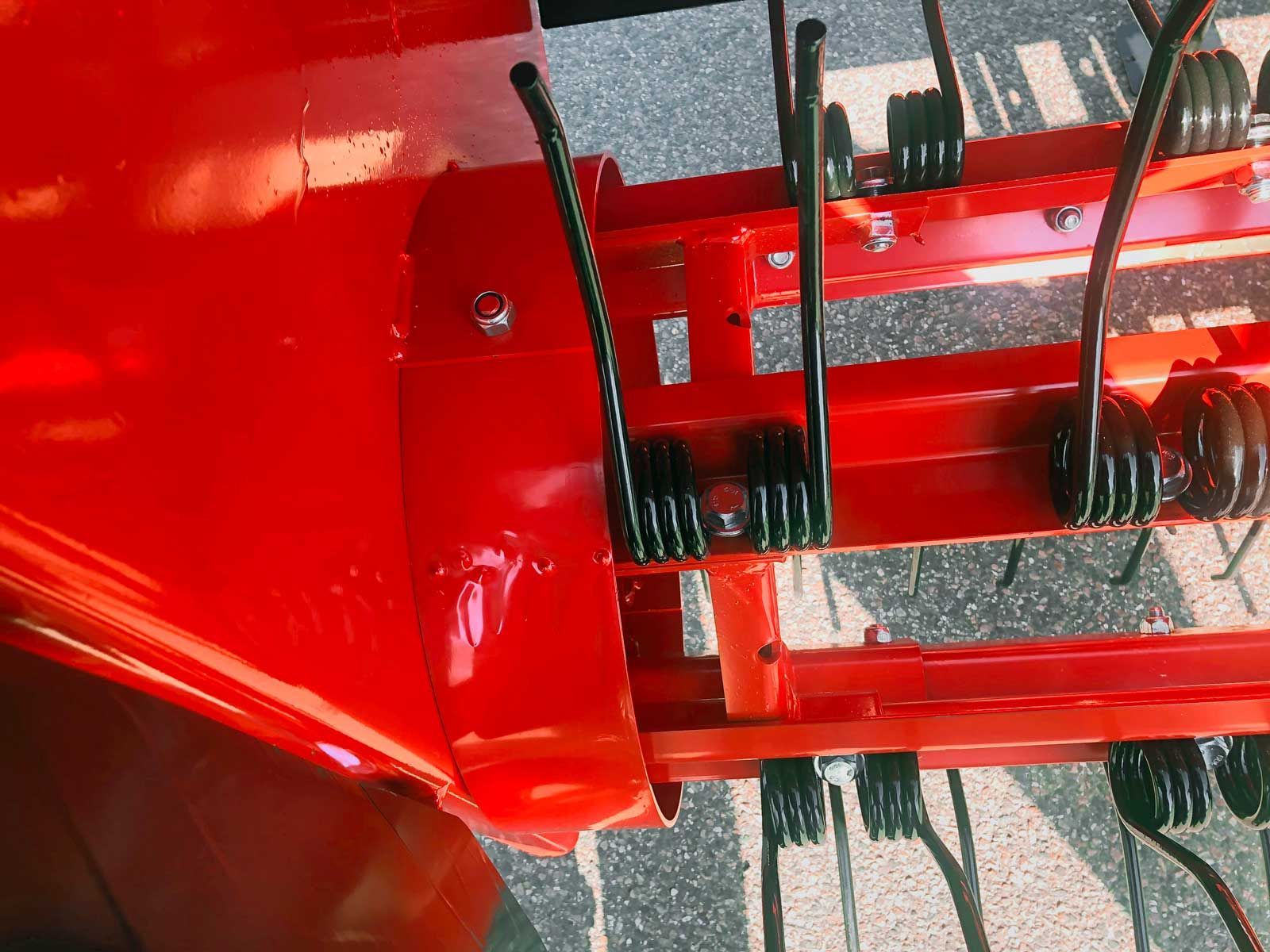

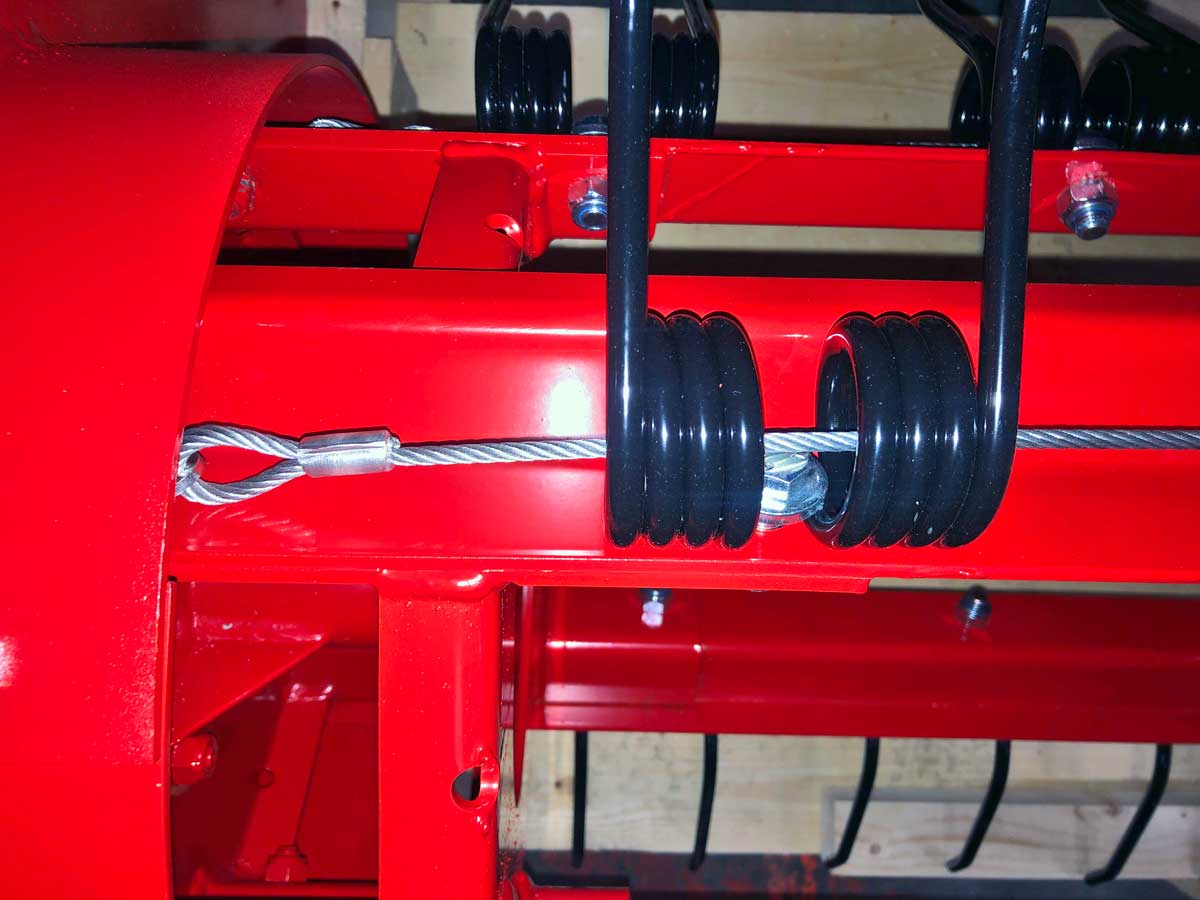

Spring, wheels

The draw spring, which is mounted on the wheel bracket, provides a smooth movement of the wheel fork and ensures that the wheels are always turned during transport.

Flange bearing

The cast flange bearing at each end of the rotor can be easily greased from the outside.

Gearbox

The robust angular gearbox has a standard vented plug that is well protected in the main frame.

Wheel suspension

The swivel wheel suspension adjusts in height without the use of tools.

Main frame

The shield above the rotor has a robust arc-shaped design with a curved edge on top and is made of Domex-420 steel grade.

Hole for lubrication

Cut-outs in the v-belt guard allow easy access for lubricating the flanged bearings.

Hole bracket

2 hole brackets on the top of the shield allow for a customised adjustment of the swath guards.

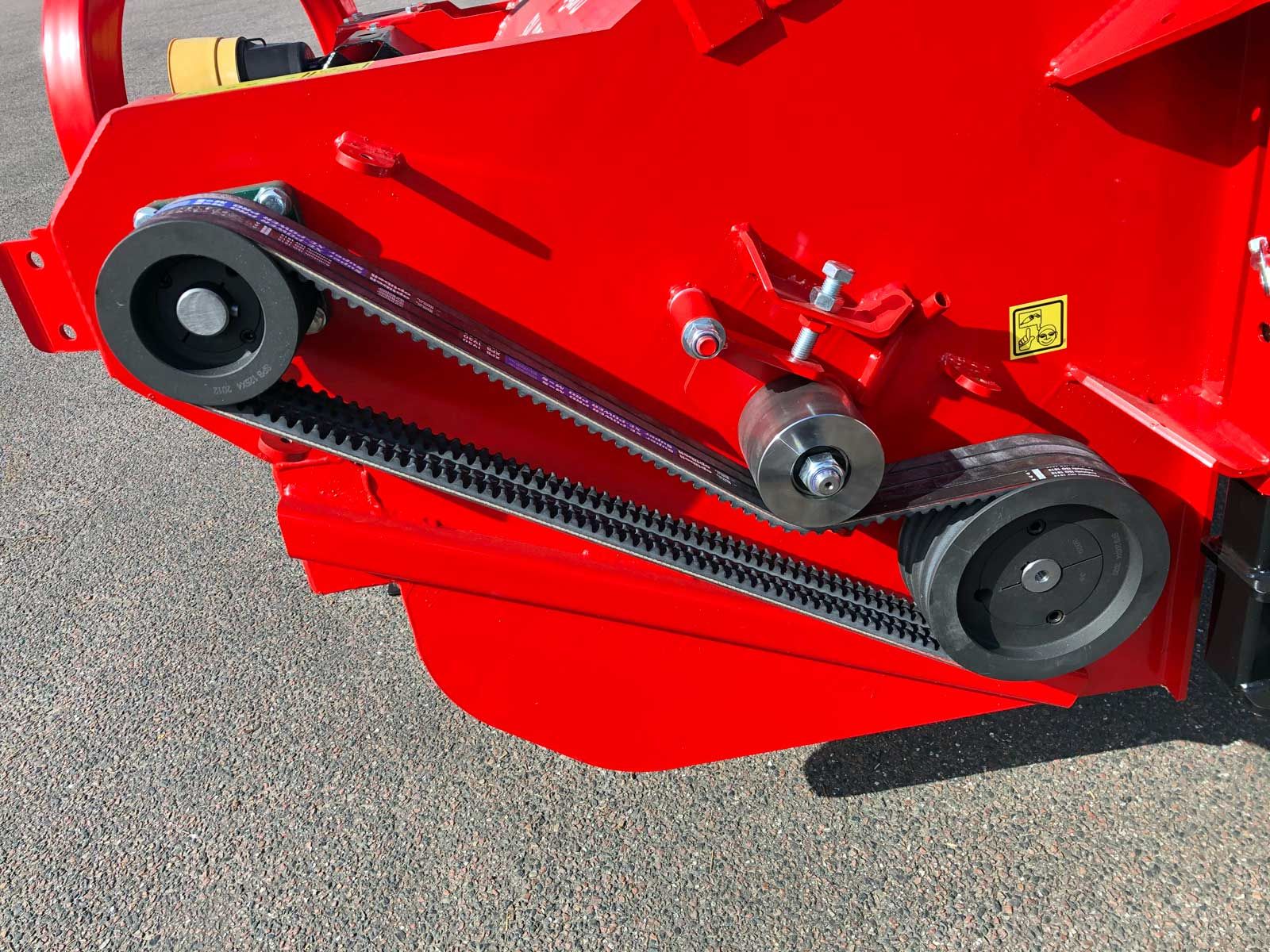

V-belt

The 4 XPB v-belts are tightened via the large tightening wheel to provide optimal operation. The placement of the tension wheel helps to achieve an even greater power out of the belt drive. (The SV-8300-CD is equipped with a chain drive.)

V-belt guard

The v-belt guard protects the belts well and is fitted with a service hatch for checking the belts.

Belt tensioner exterior

The belt tensioner on the SV-2500 is easily operated from the side of the machine.

Rotor, reinforcement

The rotor on the machine has 10 reinforcements mounted inside.

Rotor, internal

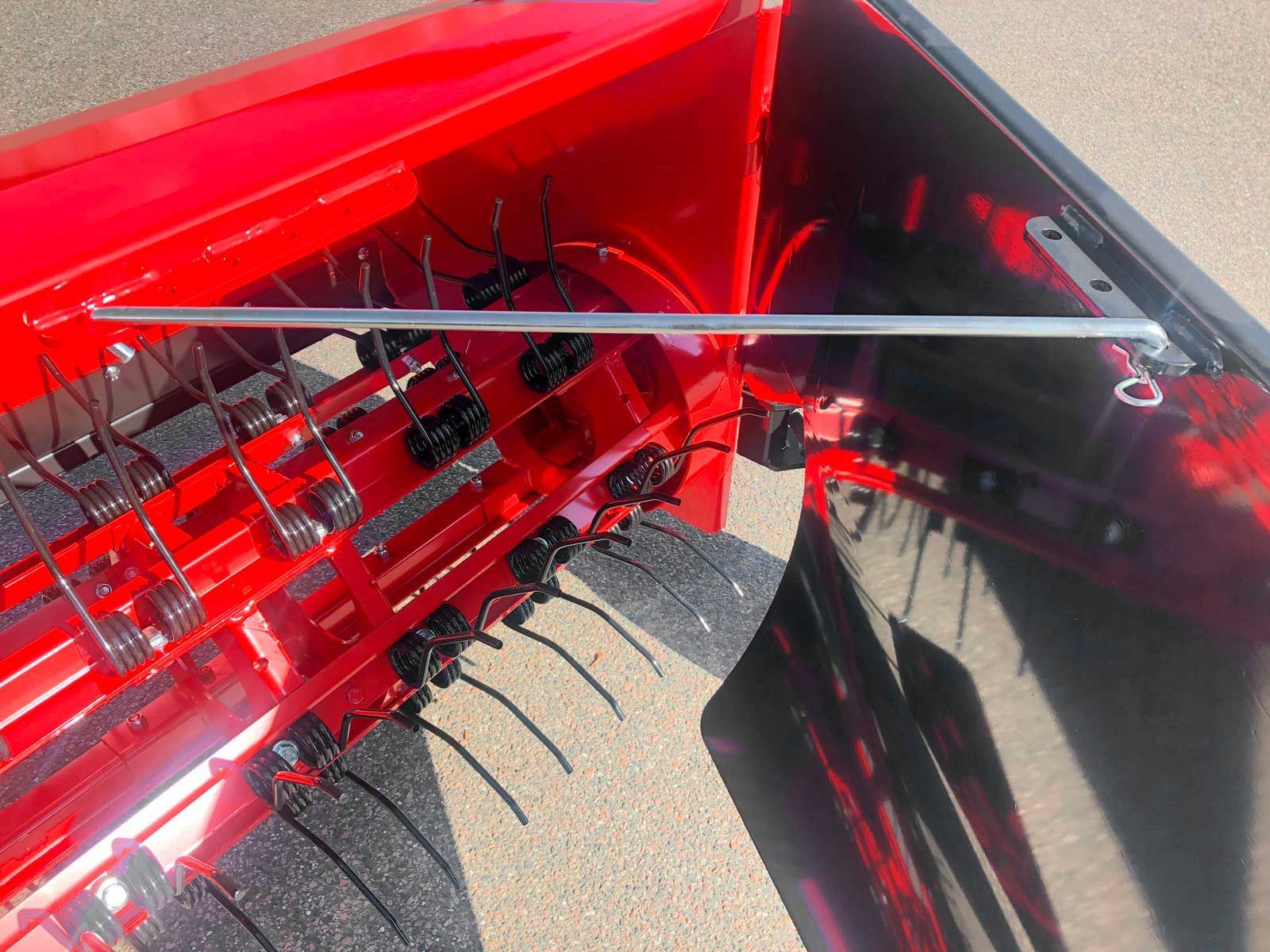

The 72 close-fitting pick-up springs have a small bend at the edge and spaced equally to the shield all round, ensuring optimum flow through the machine and a perfect swath.

Rotor

The most powerful rotor on the market has 6 rows of springs and a diameter of 80 cm. The spring rows can be replaced individually. The same applies to the 72 springs.

Guard, rotor

Wide and close-fitting guards around the ends of the rotor ensure that the material does not twist around at the ends.

Guard, exterior

The guard at the bottom of the shield can be removed to provide a 10 cm larger input into the machine, which is a great advantage when working in larger material volumes.

Swath guard

The large swath guards have a rolled arch at the bottom and thereby help to form a high airy swath. The guards can be moved in and out according to the amount of material and the desired position of the swath.

Positioning bar

The galvanised bar for adjusting the swath guard can be fitted in 6 holes on the machine and 3 holes on the swath guard.

Support legs

The support leg for parking the machine is easily swung up when coupling the machine and is therefore always carried on the machine.

Gearbox

The heavy-duty gearboxes are well protected between the lifting arms, which are fitted with a swivel joint that gives the machine a smaller turning radius.

Suspension

The machine is mounted in the lifting arms of the very strong lifting suspension, which makes it easy to connect and disconnect the machine. The lifting suspension is rolled in a square section, which gives it great strength and an attractive design.

Wheel frame

The heavy-duty wheel frame is curved in a square section and fitted with large wheels for smooth transportation, helping to follow the terrain while working with the machine. The wheel frame is adjusted up and down hydraulically.

Lights

LED lights and a warning triangle are standard equipment on the machine.

Optional extras

Item No. 4236

The tooth lock consists of 6 x 5 mm galvanised wire with a bracket. This ensures that broken springs do not fall into the swath. Can be retrofitted.

Download PDF-files

See our information material here, where you can download and print the file.