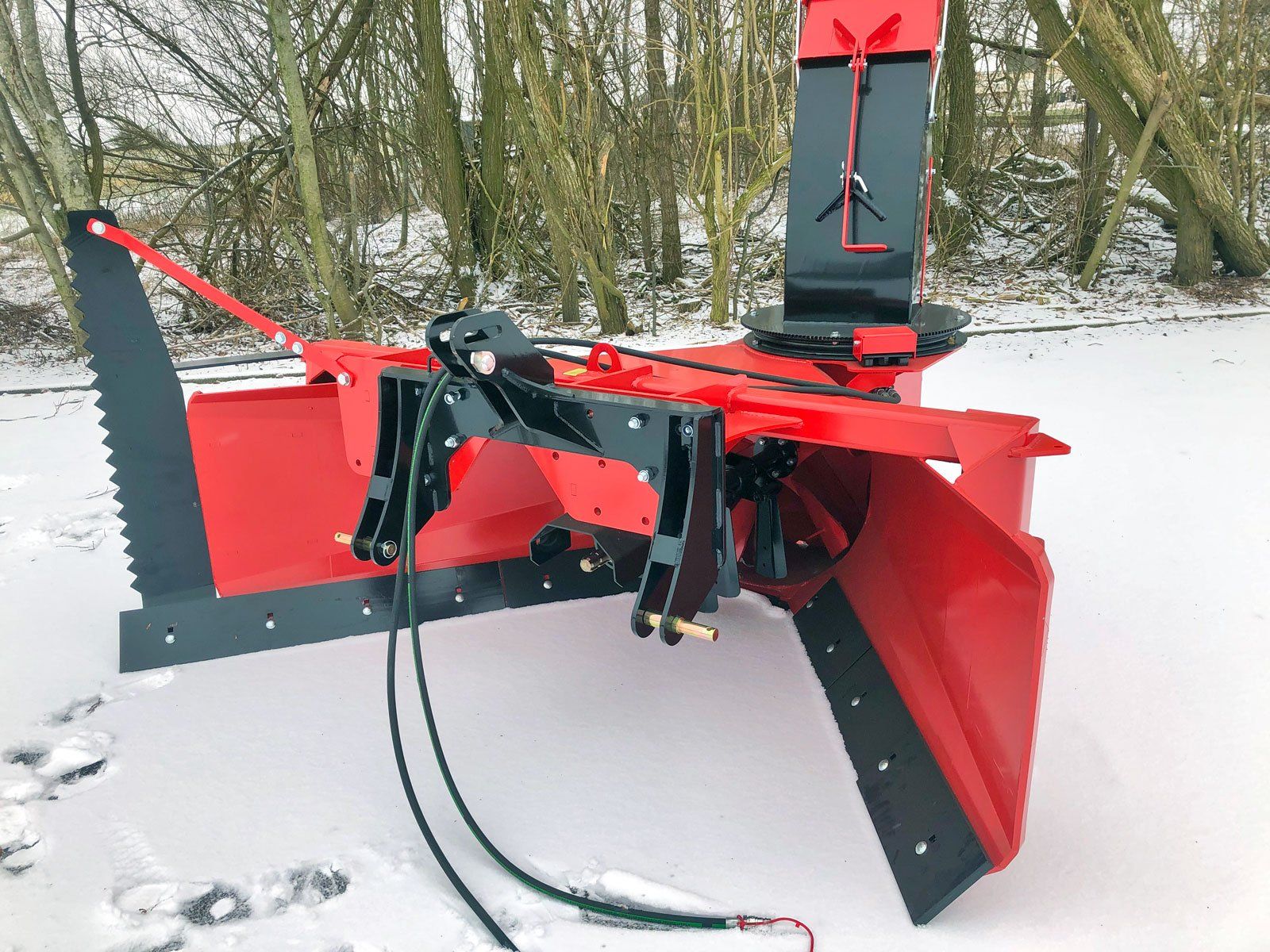

Snow blower VSF-255

Presentation

VSF-255 is Fransgård's largest snow blower in the V models. The snow blower solves the need to clear extra large amounts of porous snow quickly and efficiently. The simple and strong construction ensures high reliability, where fast and safe clearing of roads is paramount.

The VSF-255 has been made with attention to detail, to achieve the best functionality for the user and the largest capacity in its class on the market.

The construction increases accessibility

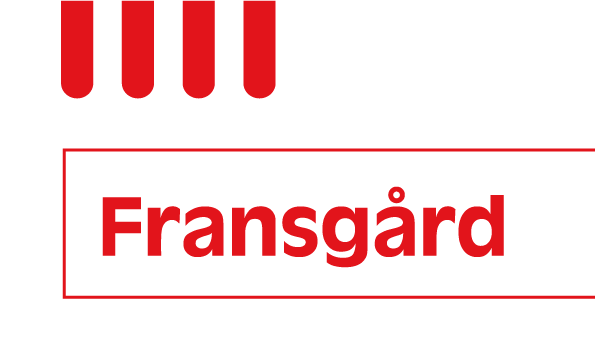

The VSF-255 snow blower is designed asymmetrically and with an offset adjustment of the suspension, it provides the best possible clearing conditions. The 5 loose feeding blades and the large 85 cm ejector fan gives a very large capacity and long throw.

VSF-255 is made with reinforced edges, double wear steel at the ends, Hardox 500 wear shoe and 80% of the blower is built in high strength steel, which together give a strength like a real 'Viking'.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Technical data:

| Model: | VSF-255 |

|---|---|

| Working width | 235/265 cm |

| Working width with edge blade r/l | + 15 / + 15 |

| Ejector fan diameter | 85 cm |

| Ejector fan housing diameter | 40 cm |

| Number of feed blades | 5 |

| Centre flap | Std. |

| Hydraulic top flap | Possible |

| Springbolt magazine | Std. |

| 3-point suspension Category II | Optional |

| HM suspension | Optional |

| PTO-pin | 1¾” |

| Power requirements | 100 HP |

| Push/front mounting | No |

| Weight | 870 kg |

Details:

3-point suspension

VSF is available with 3-point cat. II or HMV suspension. Bolted to the mounting plate where there is a possibility of an offset adjustment.

Bolt in the top flap

All S models are fitted with greasable bolts in the centre and top flaps to minimise vibration and extend service life.

Turntable

All spouts are mounted on a greasable ball bearing turntable, which allows the spout to rotate 360 degrees easily and freely. The oil engine with a gear wheel is well protected on the snow blower.

Reinforcement, bottom

The main frame is reinforced with a horizontal flat bar all around the bottom

Reinforcement, side

The outer part of the main frame is further reinforced with 2 horizontal and 1 vertical flat bars.

Main axle

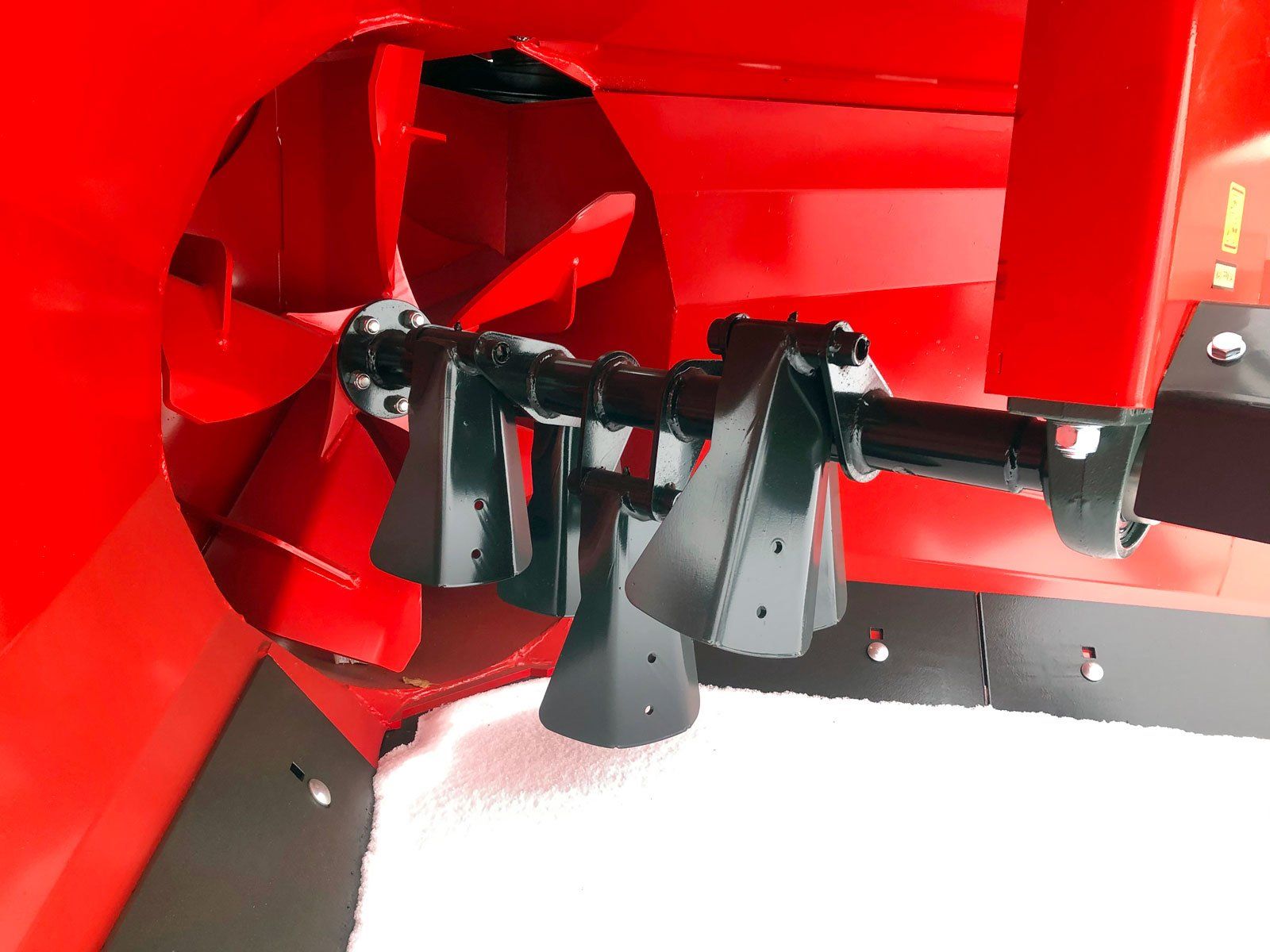

The heavy duty main axle has a 1¾" 6 spline PTO connector and has 5 loose impactors.

Main frame

Strong main frame shaped as an asymmetric V and with a solid square profile all around.

Intake fan

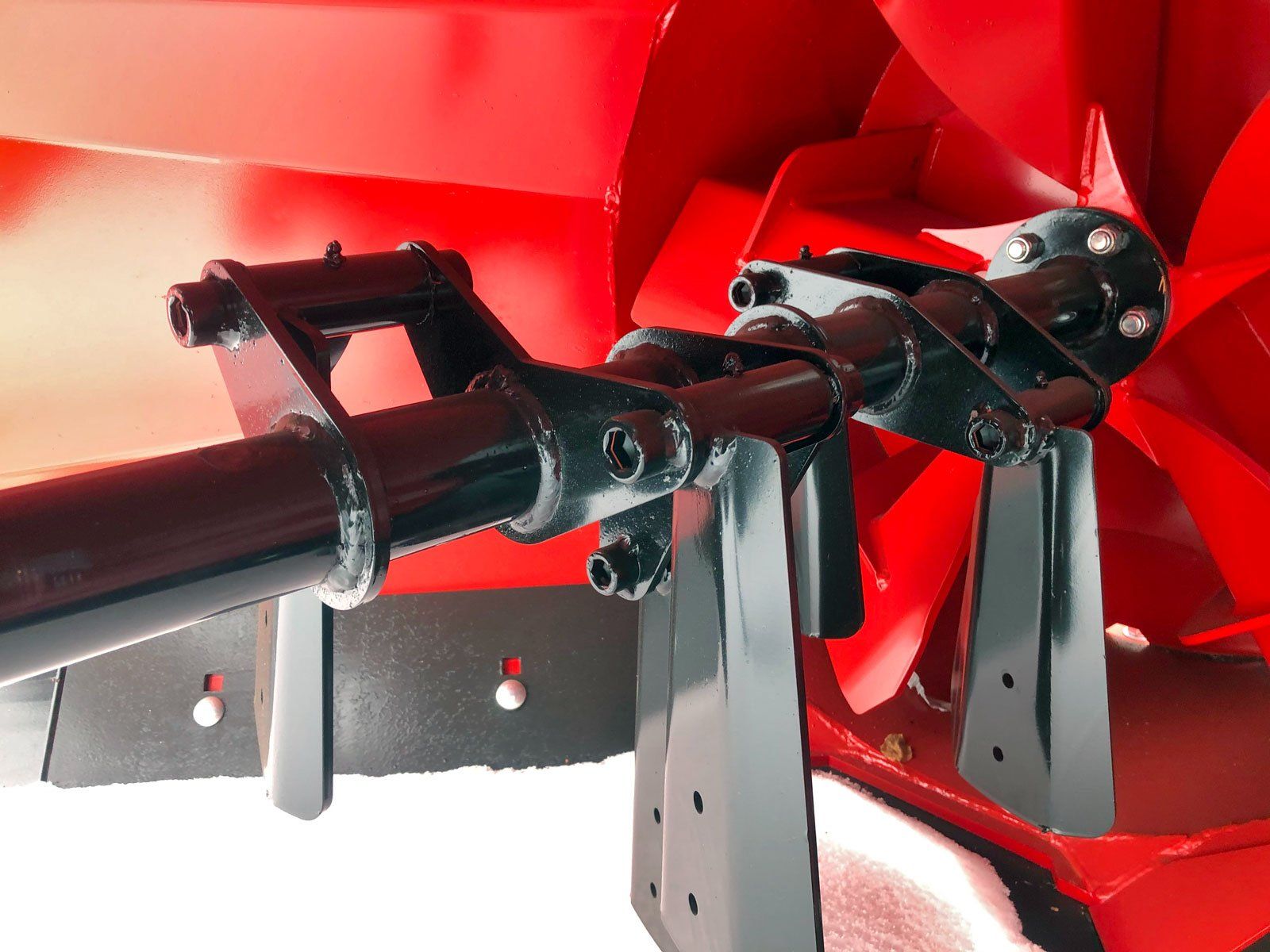

The very low intake to the fan housing allows an optimal flow of snow into the fan and thus greater capacity.

Bearing cover

The bearing cover is made in square profile with a moulded lubricatable bearing housing.

Bearing house, rear

The moulded and greasable bearing housing is mounted with 4 bolts and is well protected behind a screen.

Lifting eye

The snow blowers have standard lifting eyes for transport or moving to summer storage.

Centre and top flap

All snow blowers are fitted as standard with both a centre and top flap, which allows you to control the snow stream with great precision.

Suspension

The very strong mounting plate for suspension is prepared with holes for mounting suspension in several different positions.

PTO screen

The PTO screen is made of steel to withstand the pressure of large amounts of snow.

Safety grill, spout

The spout has a standard safety grill fitted to prevent accidental contact with the impeller.

Impactors

The 5 impactors are designed to help feed the snow into the fan, while breaking up larger clumps.

Wear shoe, rear

Rear wear shoes are located under the entire fan housing and can be replaced. The wear shoe is made of Hardox 500.

Wear shoe, side

Wear shoes in the sides are standard and can be adjusted up and down in height via a bolt. The wear shoes are made of Hardox 500.

Wear steel, edge blade

When the edge blade is fitted, the double wear steel goes right to the edge.

Wear steel

Reversible wear steel smooth/grey in special wear steel is fitted as standard. VSF has double wear steel at the ends as standard. Also available with serrated wear steel on request.

Top flap

The top flap can be angled down so that snow can be thrown down between the tractor and the snow blower when passing a side road, for example. Manual adjustment of centre and top flaps without using tools. Hydraulic adjustment is an optional extra (item no. 2227).

Top bar attachment

3-point suspension (2240). The top bar attachment has both 2 fixed holes and an elongated slot, where you can advantageously mount the top bar bolt, as the snow blower will then follow the terrain better and you will achieve a better end result.

Funnel-shaped

The funnel-shaped main frame with the slanted wear steel at the bottom ensures an optimal flow of snow into the fan.

Fan

The powerful impeller with 5 vane-shaped blades is mounted with 6 bolts on the shaft.

Fan housing

The 400 mm deep fan housing is made of Domex 420 steel, with reinforcement on the back.

Optional extras:

Item No. 1417103 PTO

PTO axle with 8 mm 8.8 springbolt.

Item No. 2227

Hydraulic cylinder for adjusting the top flap of the spout to quickly control where the snow is thrown.

Item No. 2213A

Edge blade for the right side, bolts on. The triangle ensures that the snow enters the machine. The working width is increased by 15 cm. Double wear steel at the bottom is included.

Item No. 2213B

Edge blade for the left side, bolts on. The triangle ensures that the snow enters the machine. The working width is increased by 15 cm. Double wear steel at the bottom is included.

Item No. 2240

3-point suspension cat. II bolts on.

Item No. 2242

HMV suspension, bolts on.

Download PDF files

See our information material here, where you can also read it online, print or download the file.