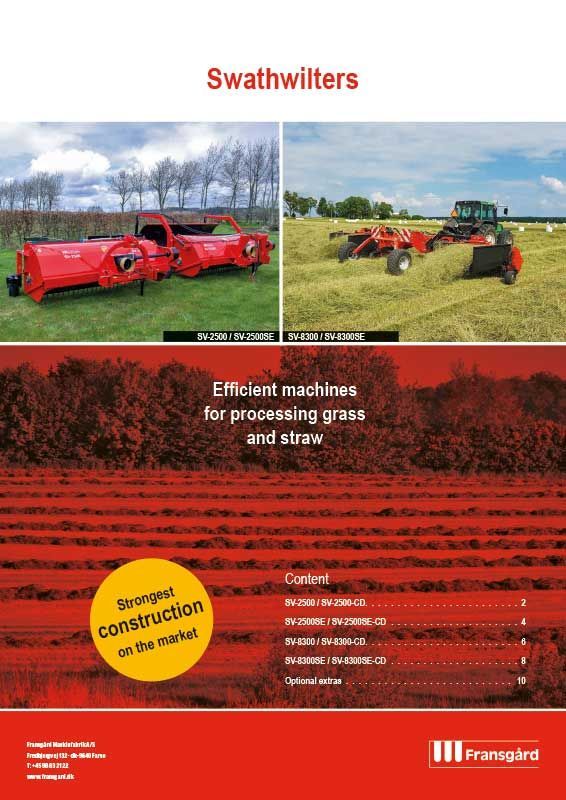

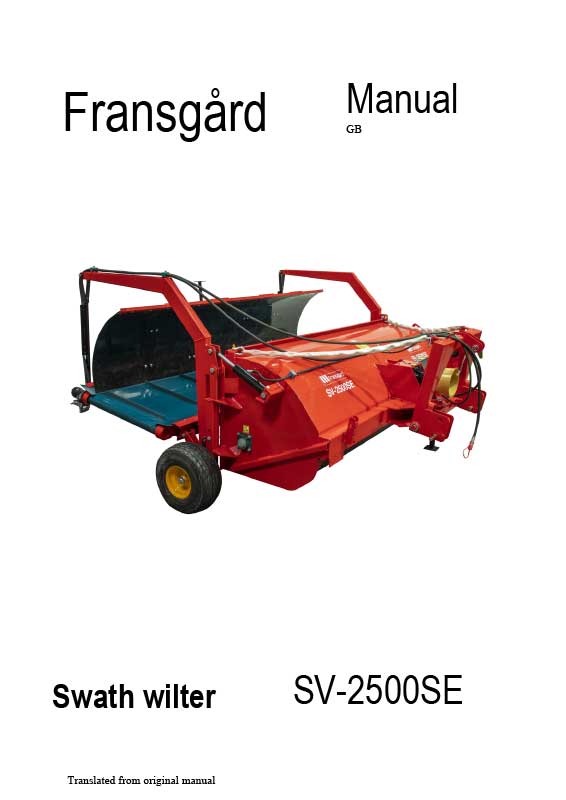

Swath Wilter SV-2500SE · SV-2500SE-CD

Presentation

Since its introduction in Sweden in 2003, Fransgård's popular swath wilters have been continuously developed and adapted to the needs of customers, while more and more markets have become aware of the machine and its qualities, which has made Fransgård the market leader in this machine.

The swath wilter is available in 2 models, one of which is with hydraulic side lift. Both models can be used to great advantage in grass, hay or straw and leave a high airy swath without impurities such as soil and stones.

In short: BETTER CROP QUALITY

Efficient swath wilter with multiple options

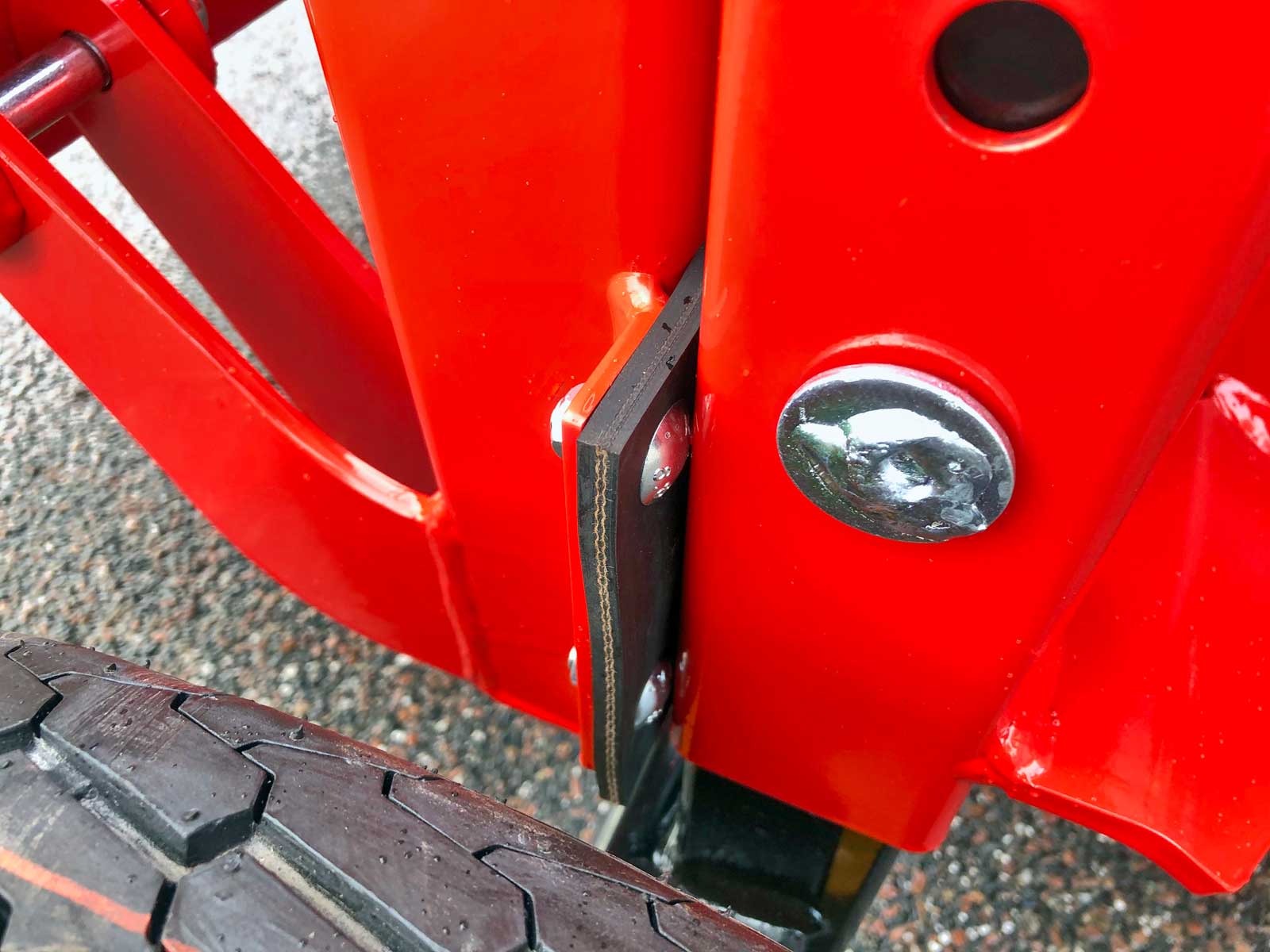

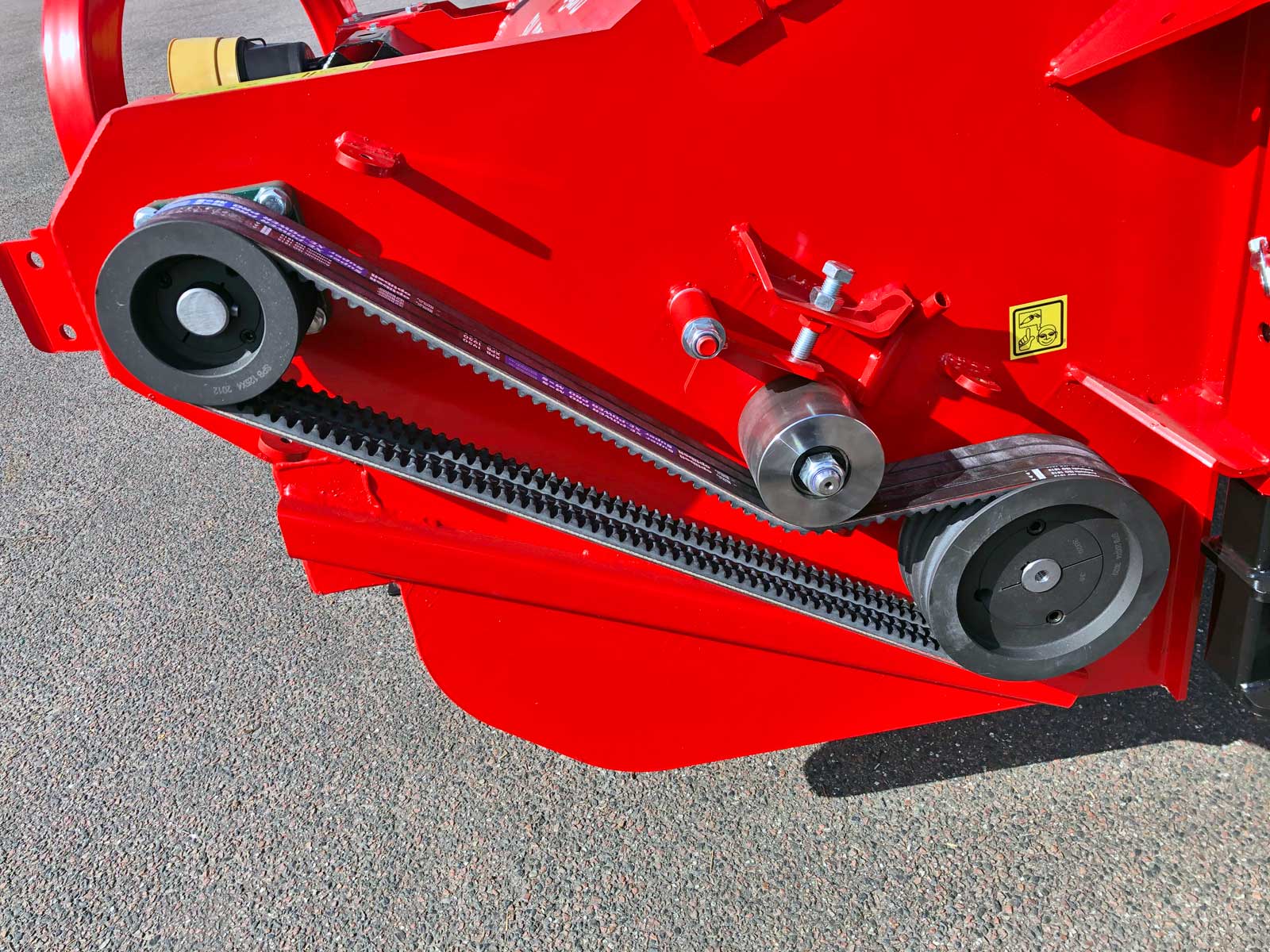

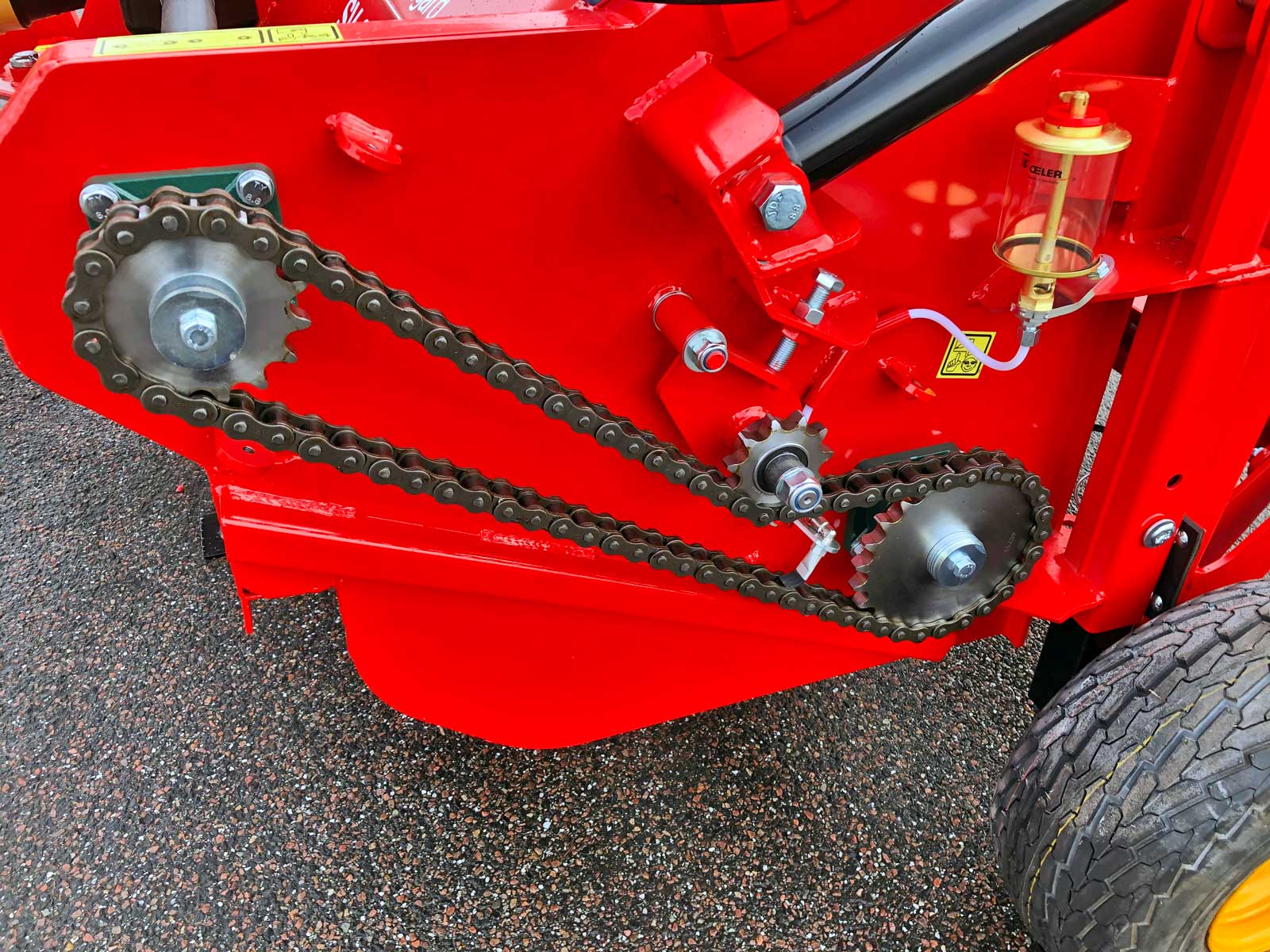

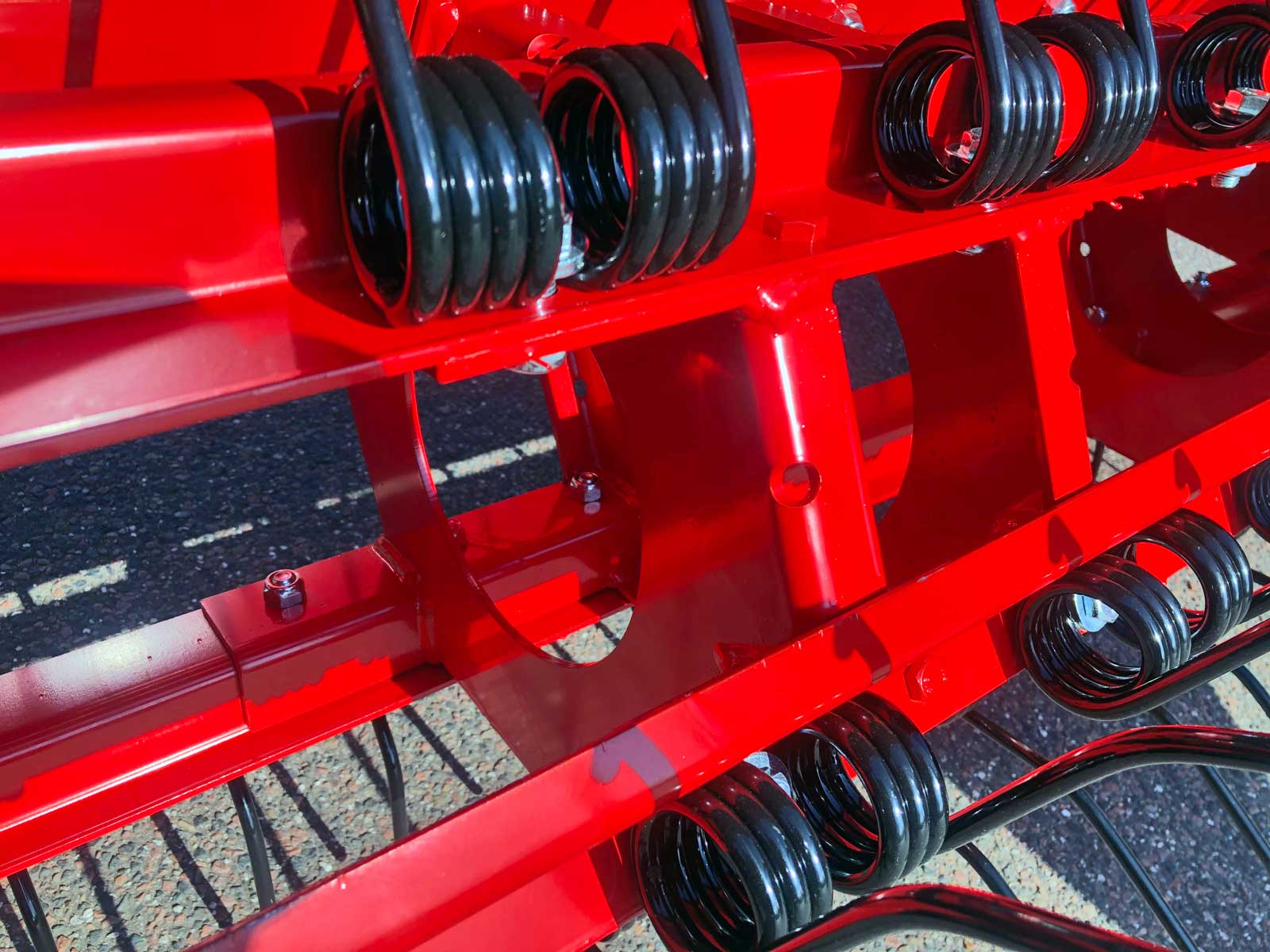

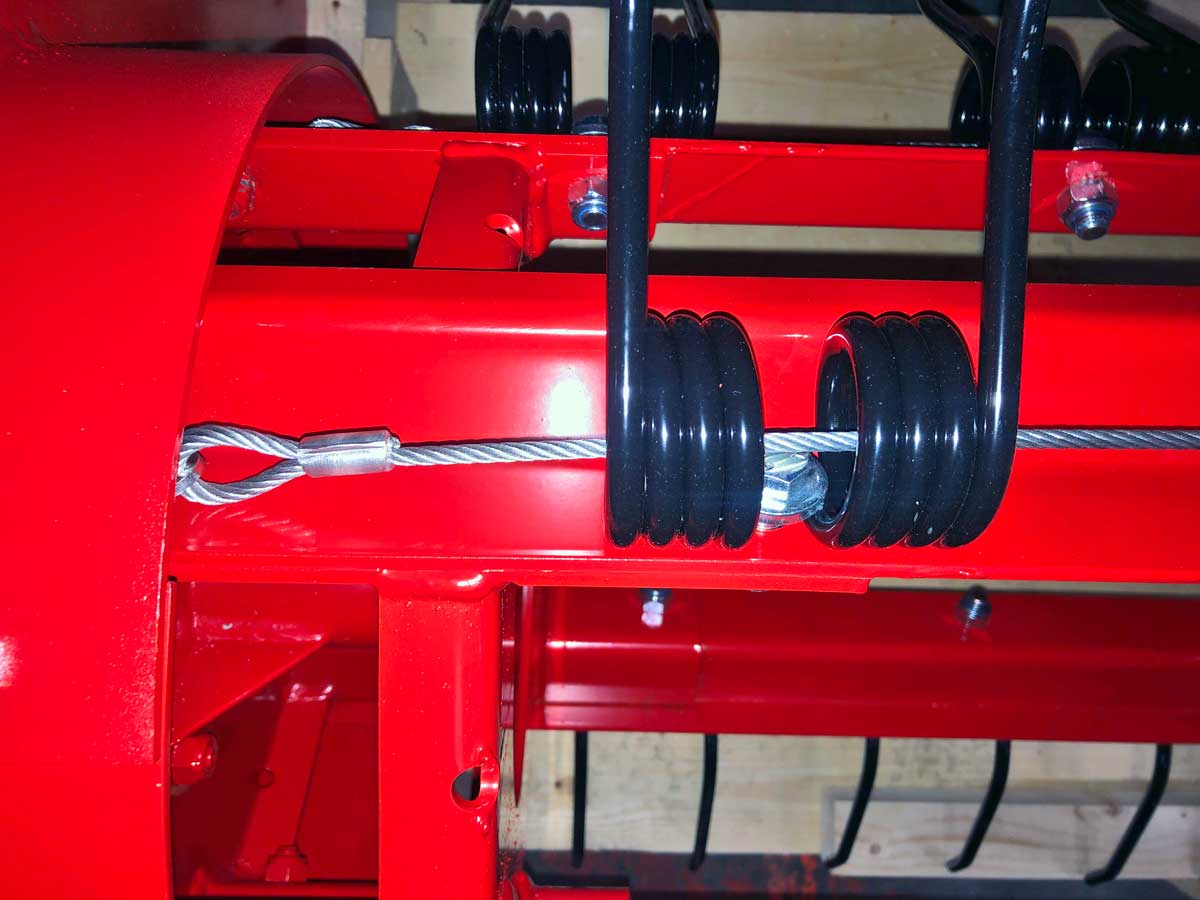

Swath wilter SV-2500SE/SV-2500SE-CD has a powerful rotor with 6 rows of springs and equal spacing around the shield, giving a uniform flow. 4 v-belts or chain drive (optional) ensure optimal operation without stopping.

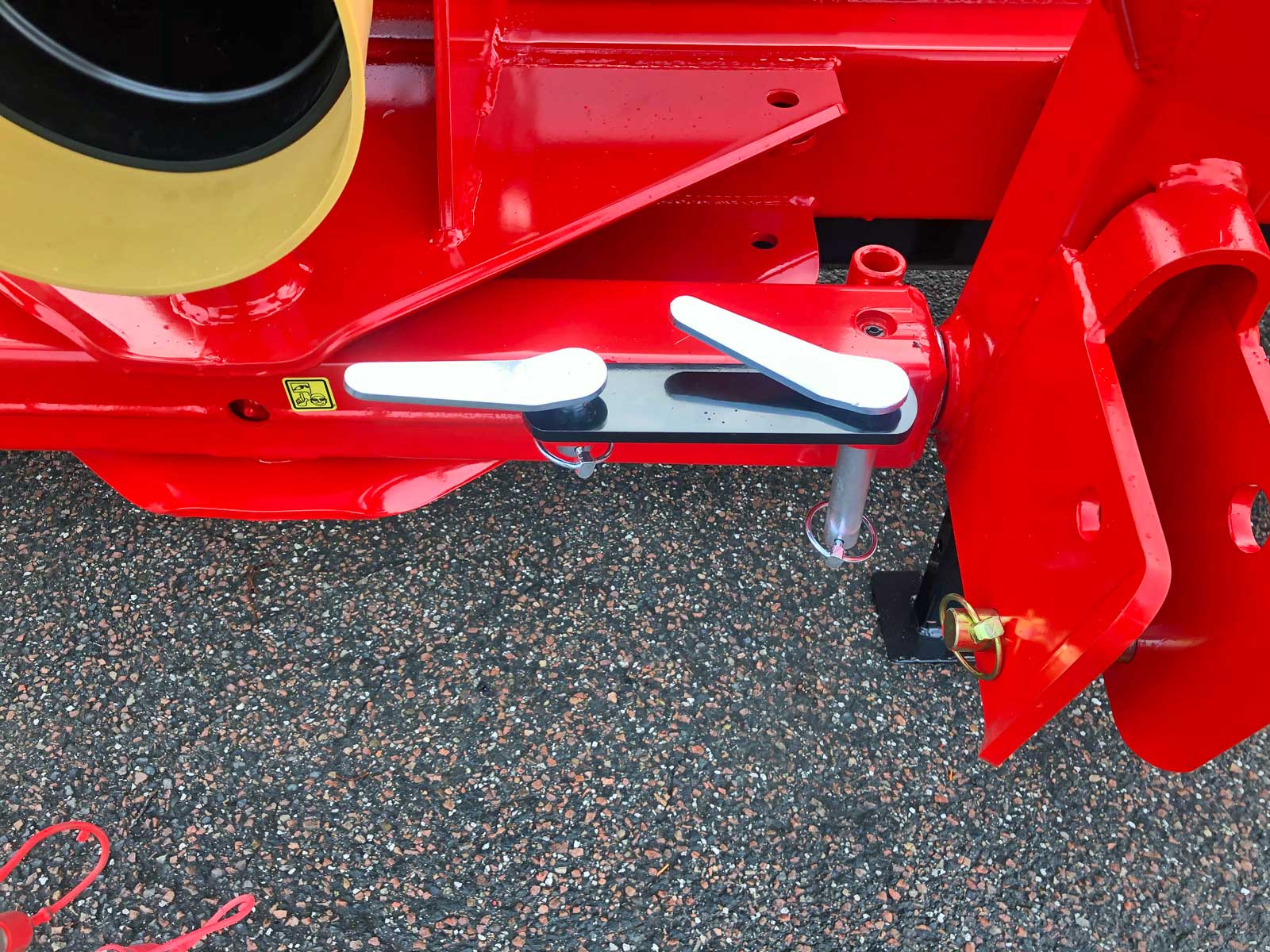

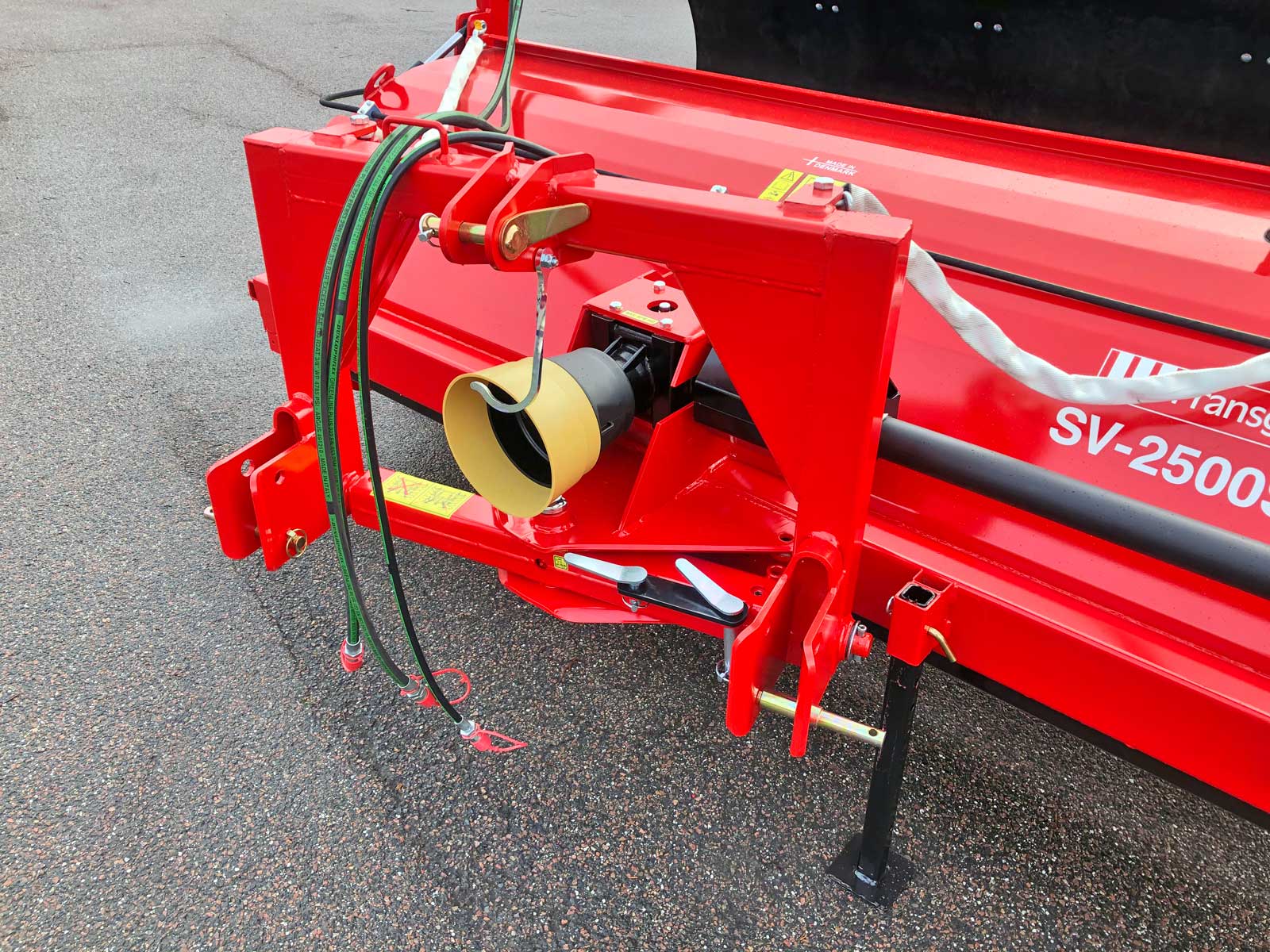

SV-2500SE/SV-2500SE-CD has the same basic design as SV-2500, but with swivel 3-point and fixed wheels. With the side lift you can move the swath to the side and set it in 3 positions. The best result is achieved when the material hits the middle of the lift. For large amounts of material, the belt can be lifted completely and swath guards (optional extras) can be fitted.

Technical data:

| Model: | SV-2500SE | SV-2500SE-CD |

|---|---|---|

| Working width | 250 cm | 250 cm |

| Transport width | 330 cm | 330 cm |

| Number of rotors | 1 | 1 |

| Rotor diameter | 80 cm | 80 cm |

| Rotor speed at 540 rpm | 485 rpm. | 485 rpm. |

| Number of rake springs | 72 | 72 |

| Number of wheels | 2 | 2 |

| Wheel size | 18.5 x 8 / 6 ply | 18.5 x 8 / 6 ply |

| Hydraulic connectors | 1 double + 1 single | 1 double + 1 single |

| 3-point suspension | Cat II | Cat II |

| PTO connector rpm | 400-540 | 400-540 |

| Power requirement kW/HP | 60 / 80 | 60 / 80 |

| Working speed km/h | 8-15 | 8-15 |

| Weight | 910 kg | 910 kg |