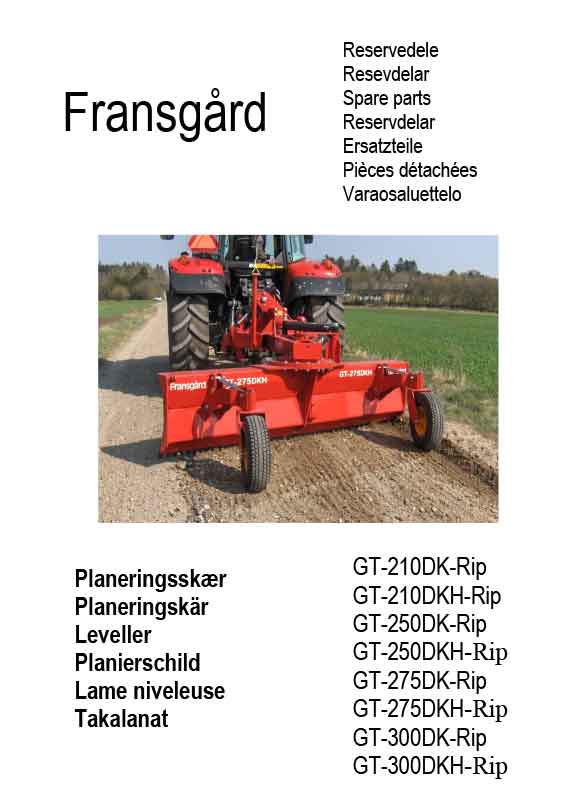

Leveller GT-250DKH-RIP · GT-300DKH-RIP

Presentation

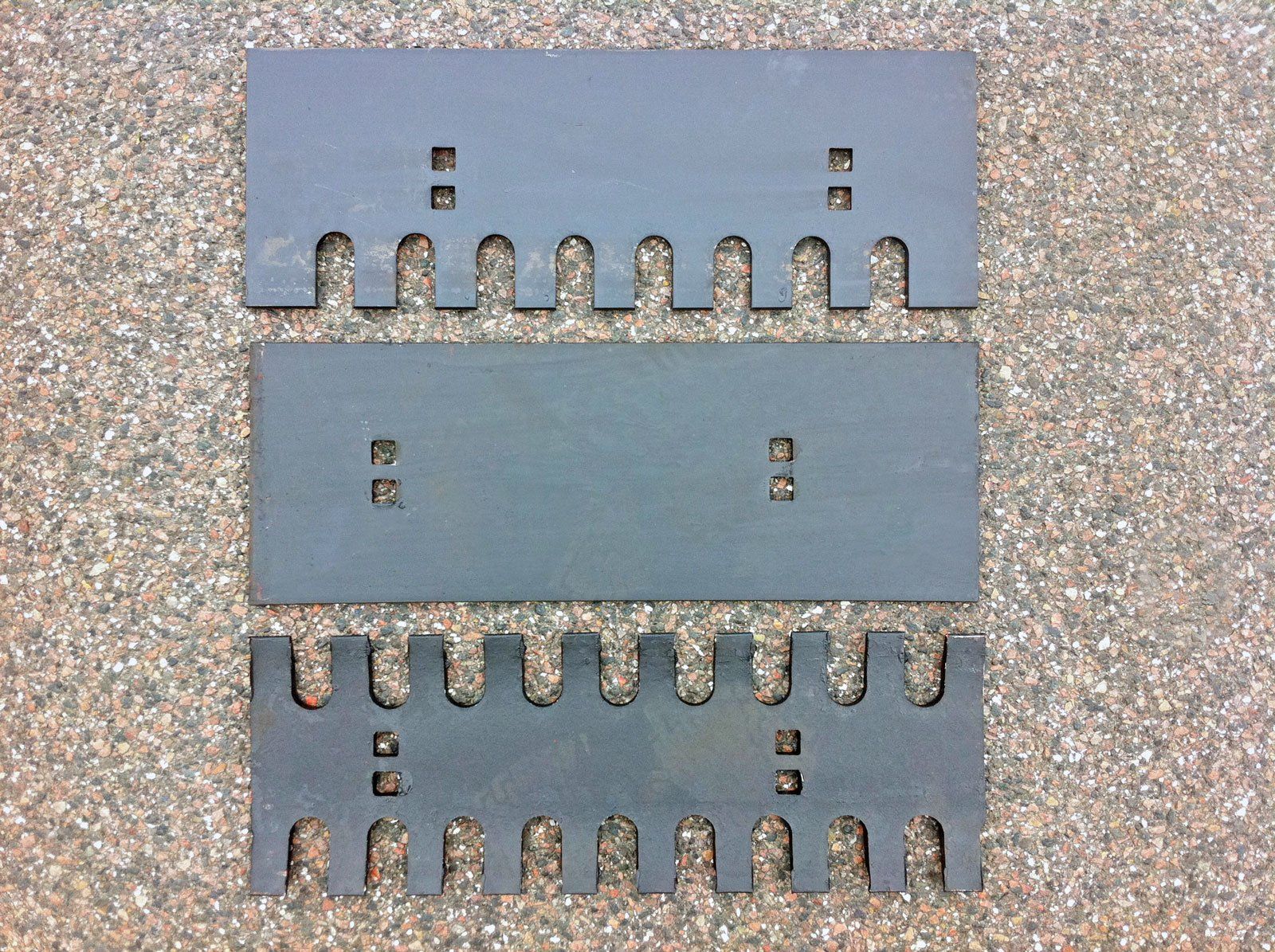

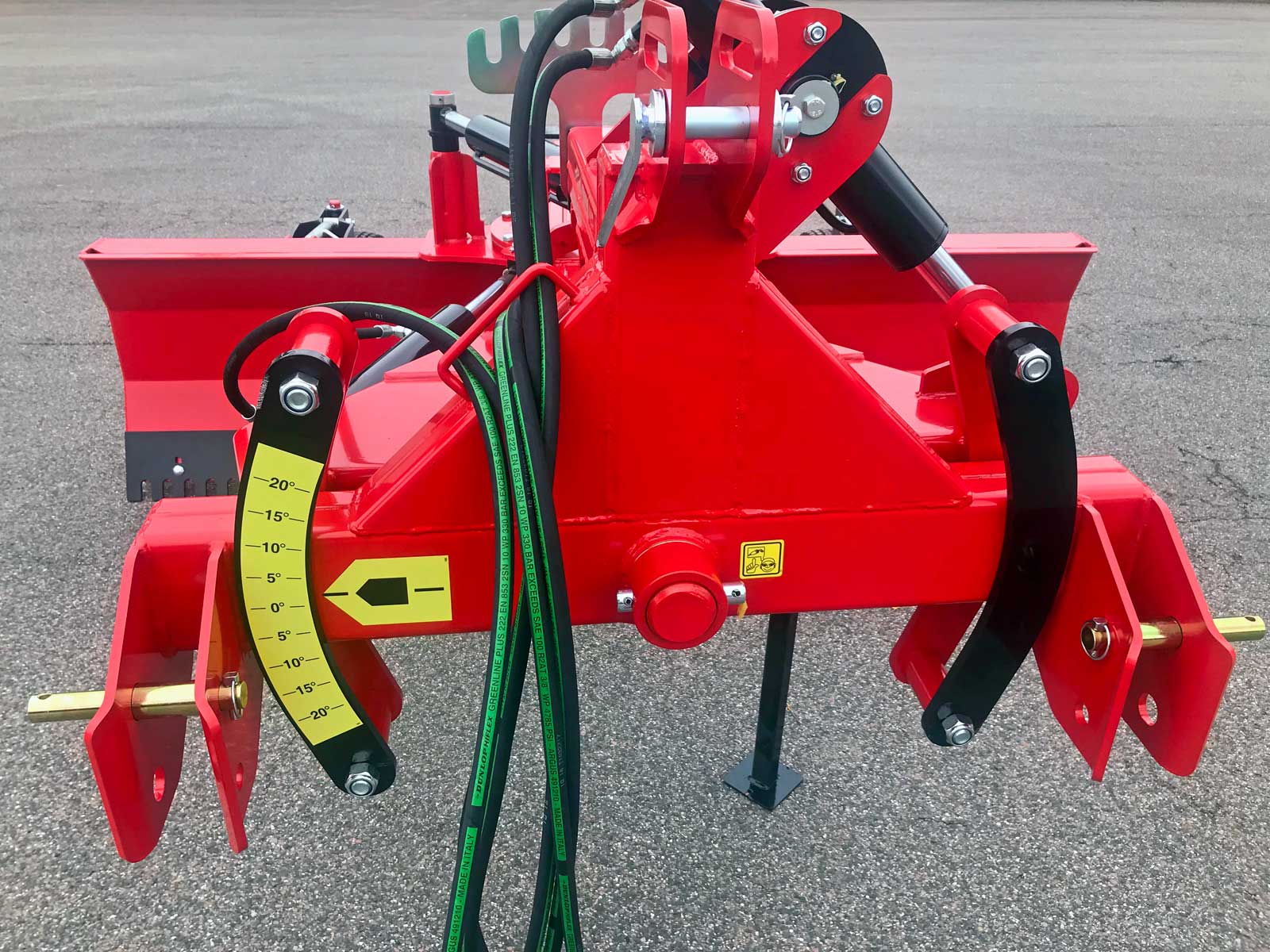

Fransgård's RIP models are constructed in the factory with particularly powerful rippers. The extra-large rippers are suitable for particularly hard-packed road material, where you want to be able to get more loose material to level the road.

The rippers can be tilted up and fastened, allowing the machine to operate as a standard model when the surface is loose enough. Therefore, an RIP model is more flexible than a standard model. The rippers can be ordered for the GT-DK, GT-DKH and GT-AUS models. They cannot be retrofitted and must therefore be ordered as an RIP model when placing the order.

The RIP models all have the same great advantages as the GT-DK version. Here you get a leveller that always gets down into the road material and easily makes a road slope, so water easily runs off the road.

Details that enhance quality

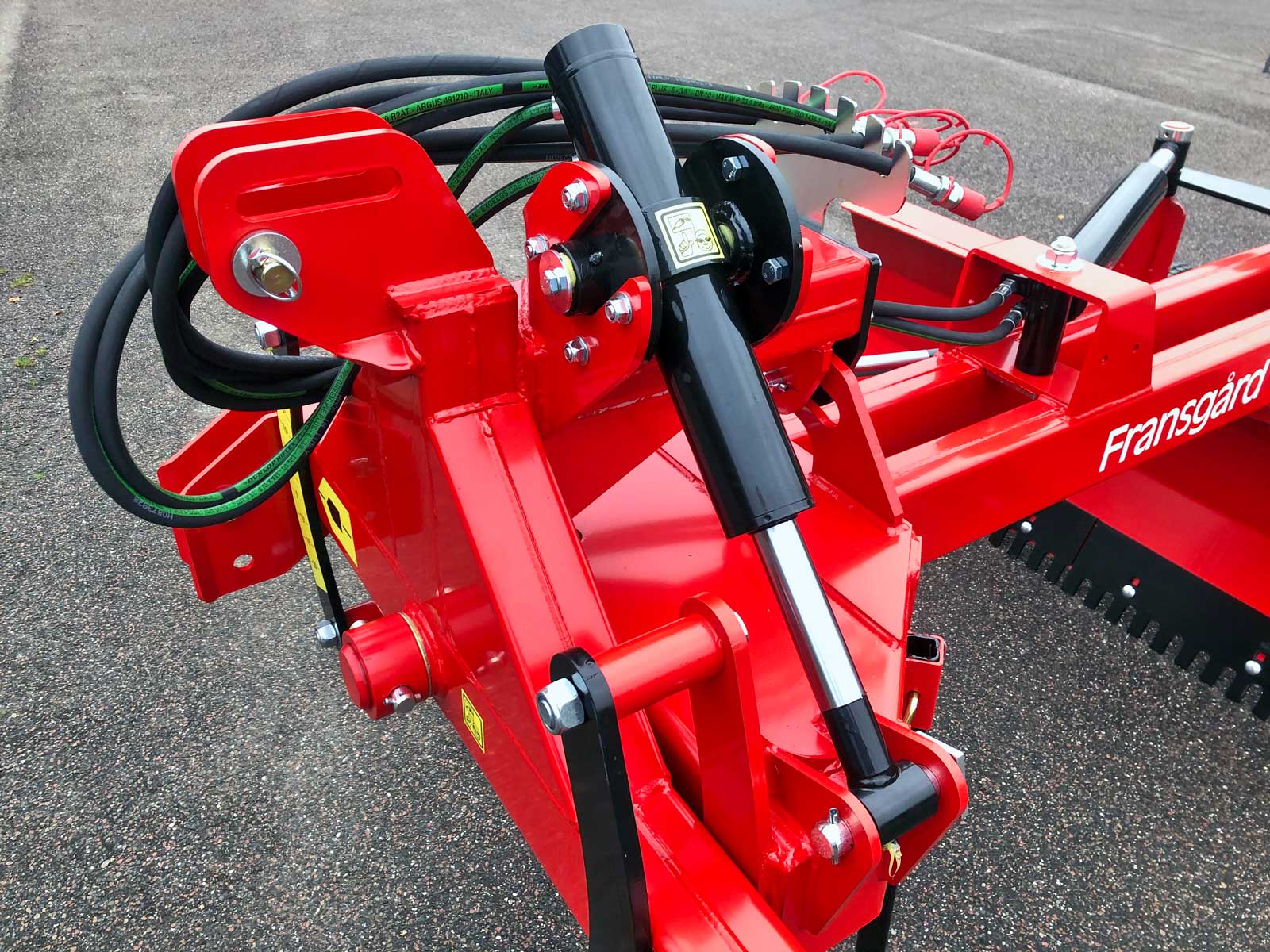

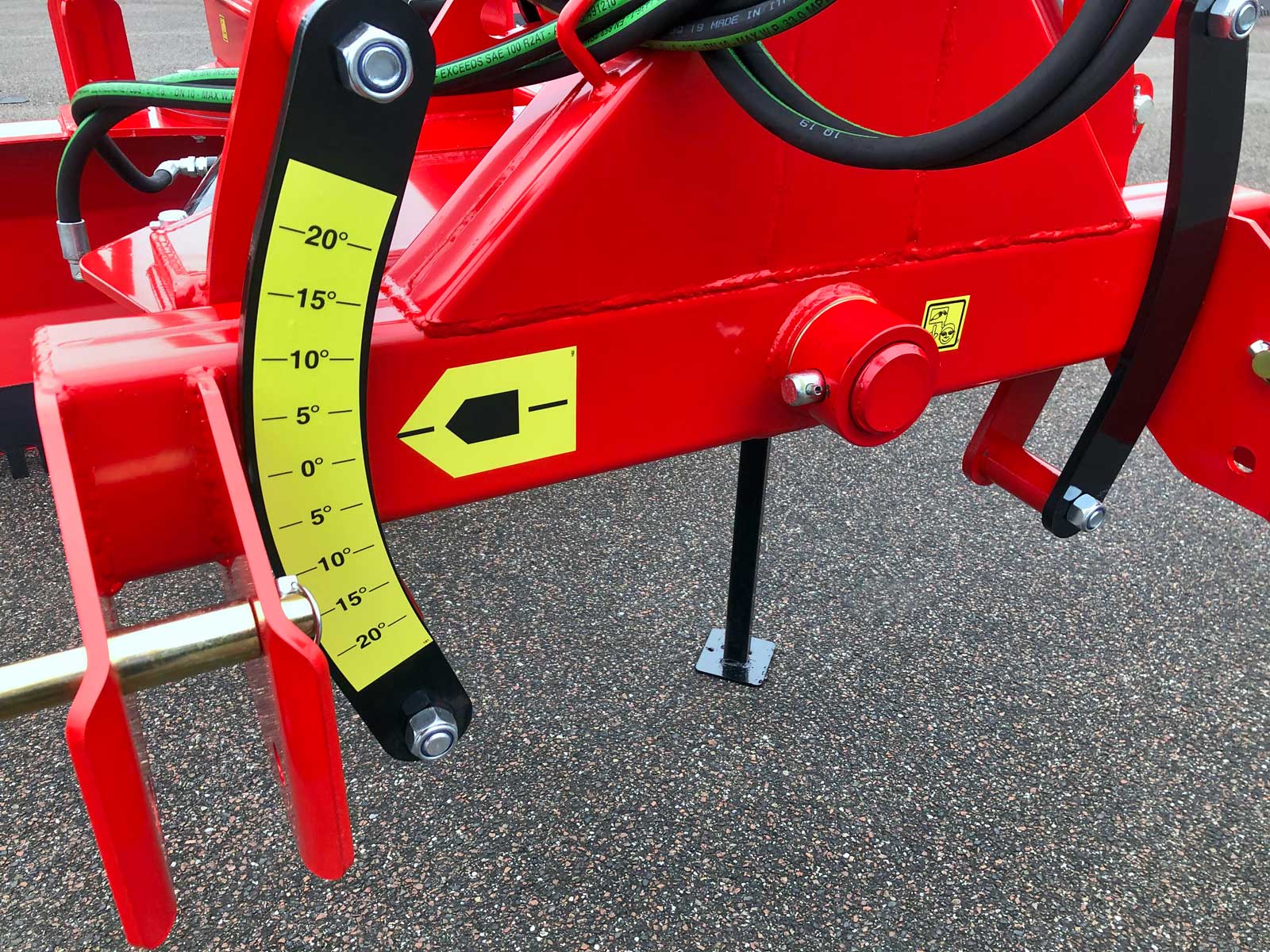

GT-DKH sets a new standard in professional cutting. The icing on the cake is the 3-point suspension design, where the horizontal angle is set up to 20° to each side between boom and hitch, thereby not stressing the lift arms on the tractor. This reduces wear and thus costs.

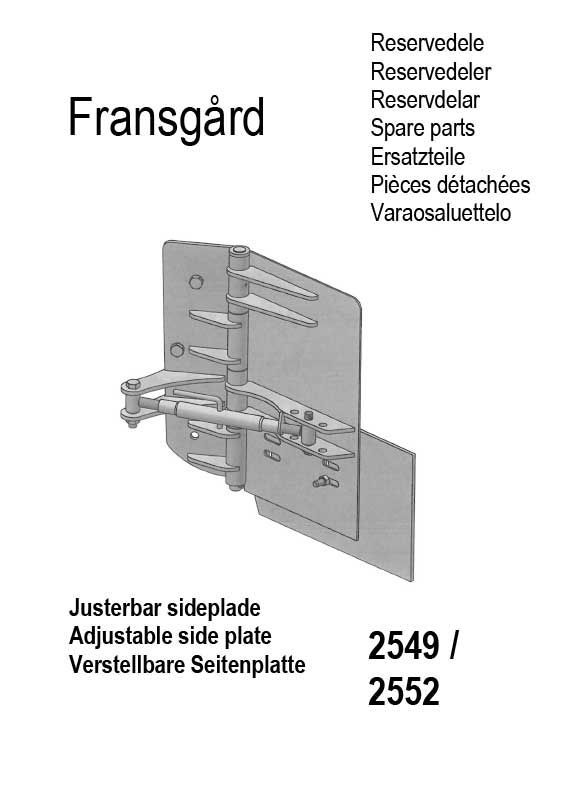

Mounting bracket for hydraulic cylinder and wear steel for the blade are made of Hardox 500. Heavy reinforcements on the back and on the side of the blade. On the side of the blade there are holes for mounting the snow blade and side plates.

The back of the blade is designed to push excess material into the road by backing up the blade without turning it - a great advantage when approaching an asphalt road, for example.

Technical data:

| Model: | GT-250DKH-RIP | GT-300DKH-RIP |

|---|---|---|

| Working width | 250 cm | 300 cm |

| Blade height | 70 cm | 70 cm |

| Mechanical offset adjustment, right/left or hydraulic (Optional) | 60 cm | 60 cm |

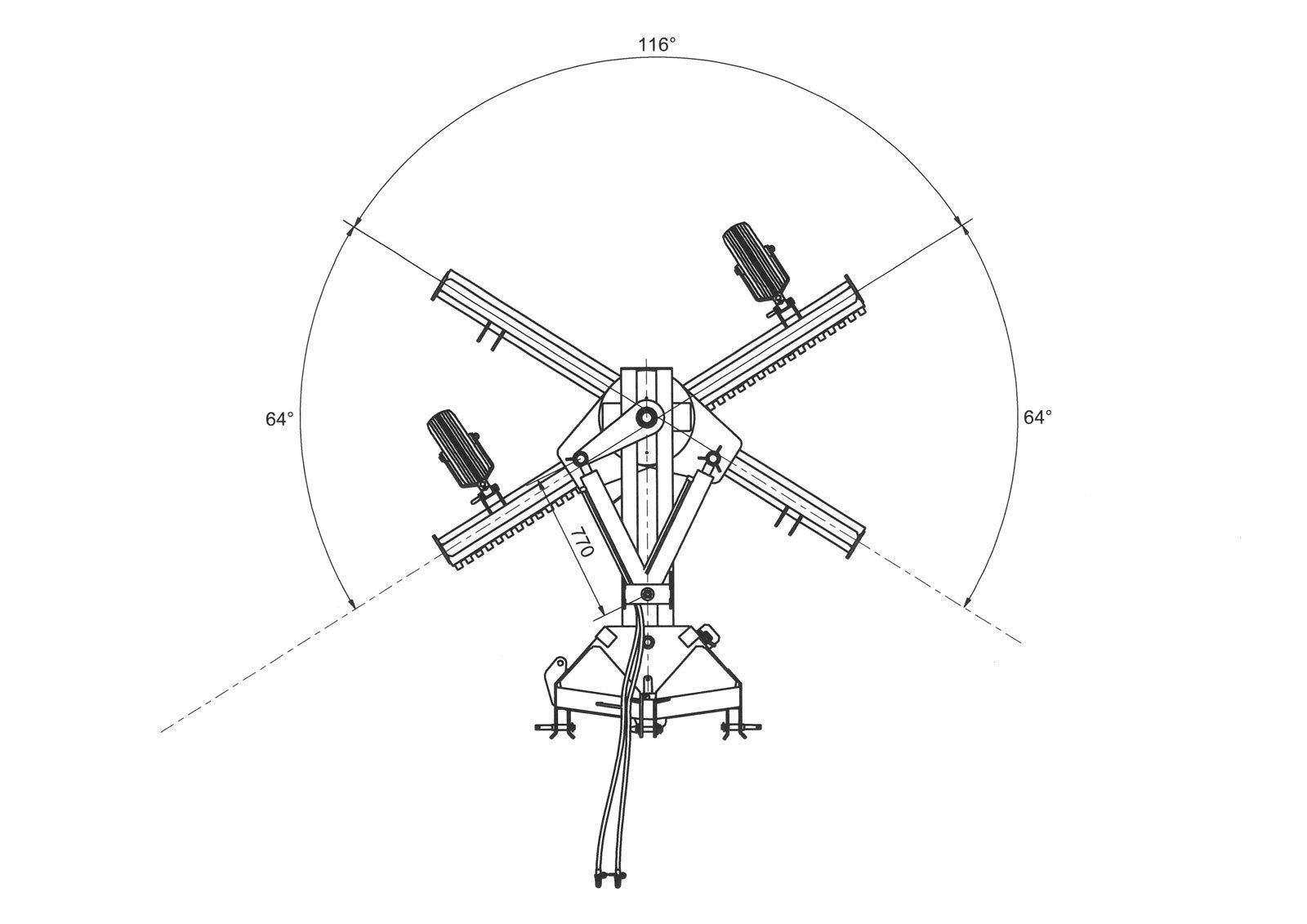

| Hydraulic rotating blade | 244° | 244° |

| Horizontal adjustment hydraulic | 20°/20° | 20°/20° |

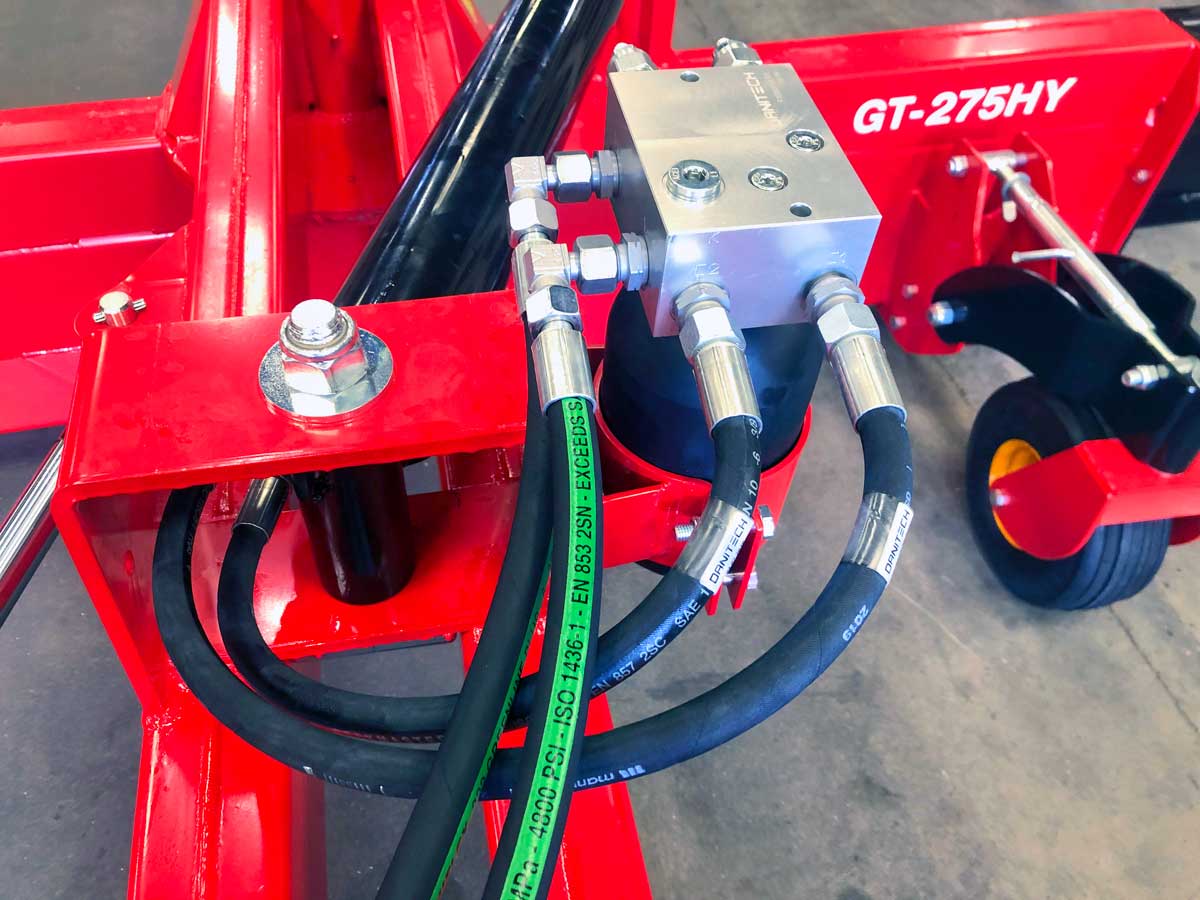

| Hydraulic connectors | 3 double | 3 double |

| Reversible wear steel Hardox 500 | Std. | Std. |

| Push/front mounting | Yes | Yes |

| Support wheels | Std. | Std. |

| Snow blade, right | Possible | Possible |

| Side flap | Possible | Possible |

| 3-point suspension | Cat III | Cat III |

| Weight | 940 kg | 975 kg |

| Number of rip teeth | 5 | 8 |

| Tractor performance | Max. 150 HP | Max. 150 HP |

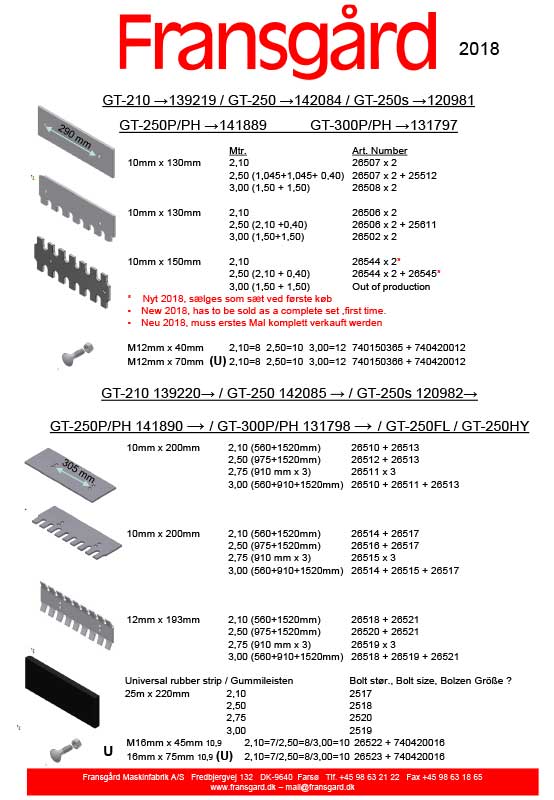

Download PDF files

See our information material here, where you can also read it online, print or download the file.