Disc Spreader STS-1800GA

Presentation

Fransgård's self-loading disc spreader is built in a robust construction. With the many well thought-out features, you get a very reliable machine. The galvanised container ensures long machine life - even in extreme working environments.

The machine is suitable for larger spreading jobs with different spreading materials such as coarse sand, sand/salt, fine gravel or similar material.

Strong and well thought-out construction

The spreader box is made of high strength steel (Domex 420) with wear steel on the top and bottom. The disc and closure fitting are made of stainless steel. The machine has a powerful hydraulic motor and a chain drive with a powerful tension wheel for operating the auger and agitator. The diameter of the auger is the minimum and grows steadily in size (progressively) towards the centre of the spreader to the disc. This provides a smoother flow of material to the disc, reducing the risk of clogging and reducing wear on the parts.

The spreader has an adjustable opening for the disc and hydraulic closing fitting for the supply of spreading material. The spreading symmetry can be hydraulically adjusted to spread from 2 up to 10 metres wide. The construction also consists of large, solid valve block with the option of manual control that is prepared for electrical control.

Optional suspension: 3-point, Volvo BM and HMV. There is the option of a 3-point loading cylinder.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Technical data:

| Model: | STS-1800GA |

|---|---|

| Working width | 2-10 m |

| Transport width | 232 cm |

| Container volume | 1800 L |

| Box dimensions, top | 220 x 120 cm |

| Spreading quantity | 5-250 g/m2 |

| Spreading symmetry | Stepless |

| Self-loading | Options |

| Agitators | Standard |

| Operation | Hydraulic |

| Oil quantity | 80 L |

| Oil pressure min. | 150 bar |

| Suspension/attachment | Optional |

| Weight | 733 kg |

Details:

Back

The back of the spreader box is bent and reinforced at both top and bottom to achieve a very robust and stable construction.

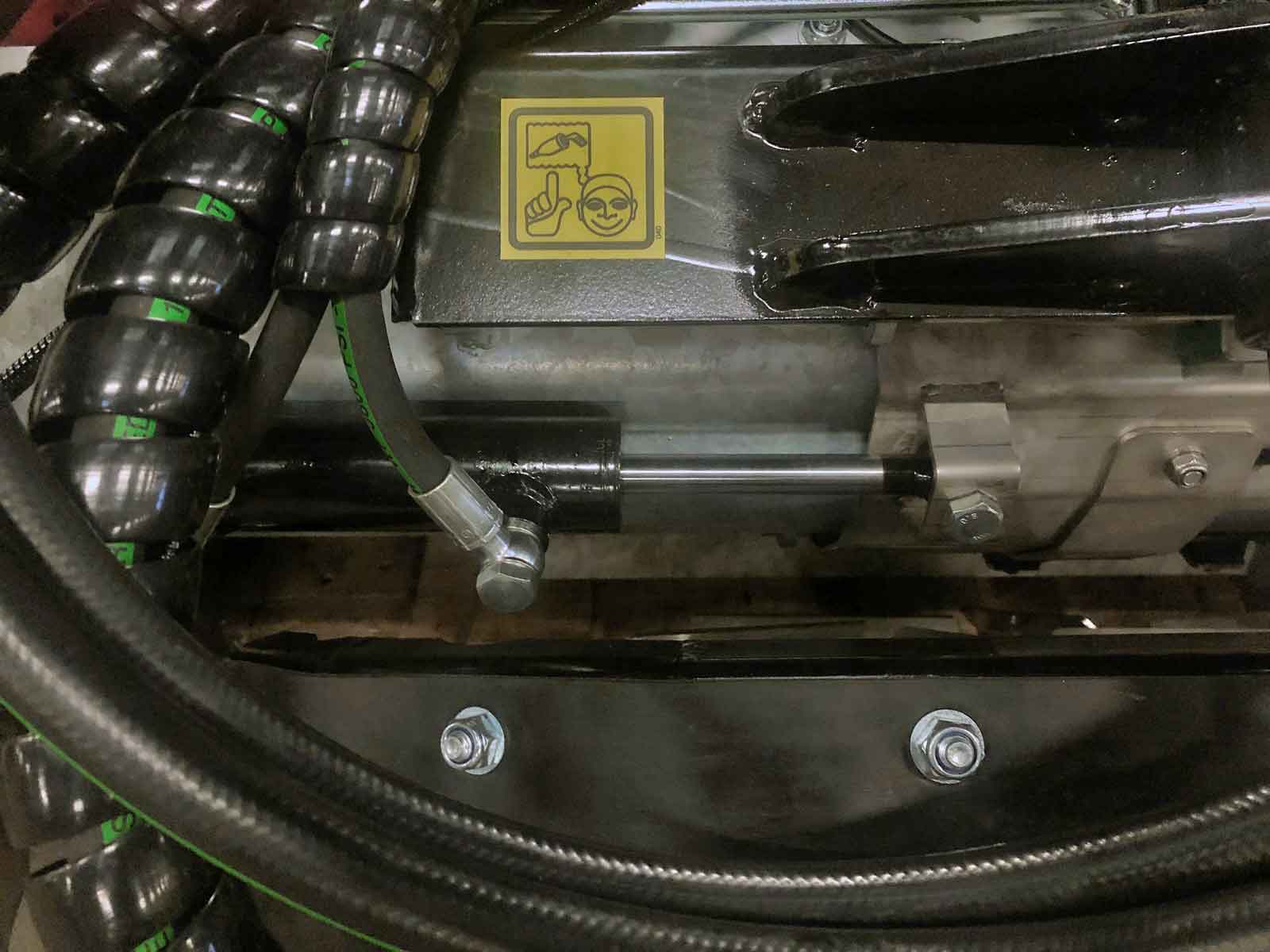

Cylinder control of the shield

A small robust cylinder with stainless steel rod ensures optimal operation of the opening and closing function of the shield.

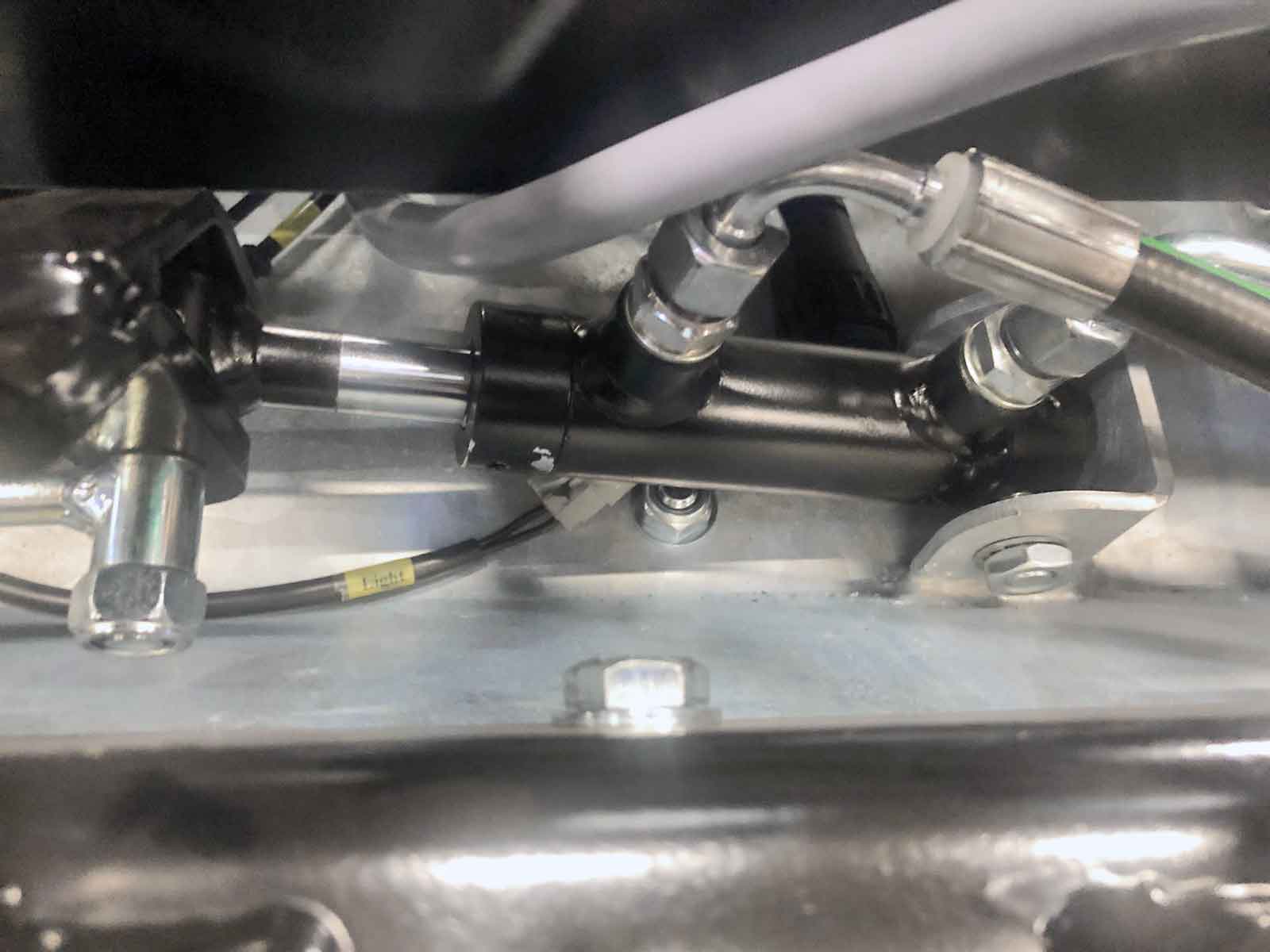

Cylinder control of the disc

A small compact cylinder hydraulically turns the spreader disc in the desired position to both the right and left.

Cover plate

The cover plate over the auger ensures that the pressure on the auger is not too great, so that it cannot rotate.

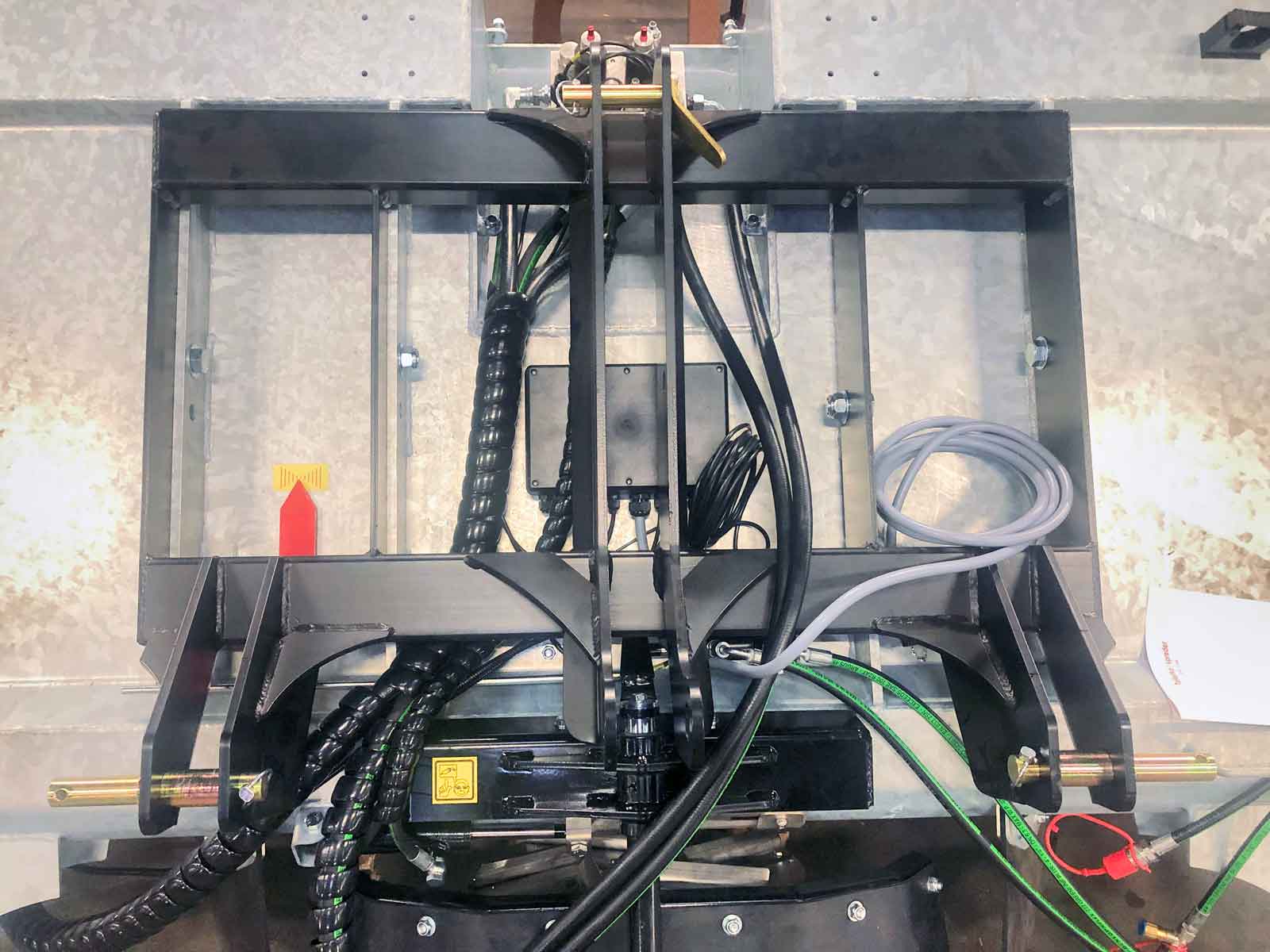

Electric control box

Electric control of all functions of the spreader (optional extra item no. 3708) watch the video.

Reinforcement of the sides

Reinforcements at the top of the side of the spreader box provide high stability. The support leg can also be rotated and mounted on the side while working with the machine.

Reinforcement, front

The box is reinforced all along the top, so it is well protected and durable when self-loading with the machine.

Safety grill

Safety grills on the top of the spreader ensure that arms or legs do not get into the machine and that, for example, large stones do not get into the machine when loading materials.

Rubber guard

Rubber guards around the disc are standard equipment, minimising the amount of material thrown forward.

Holder for the support leg

The excavation bucket holder is standard equipment on the STS-1800GA

Box design

The design of the spreader box provides a compact machine that sits close to the tractor but can still be used as a self-loader. The whole spreader box is hot-dip galvanised and all painted parts are treated with a special primer.

Chain guard

The strong chain guard is fitted with an edge strip and protects the chain drive well.

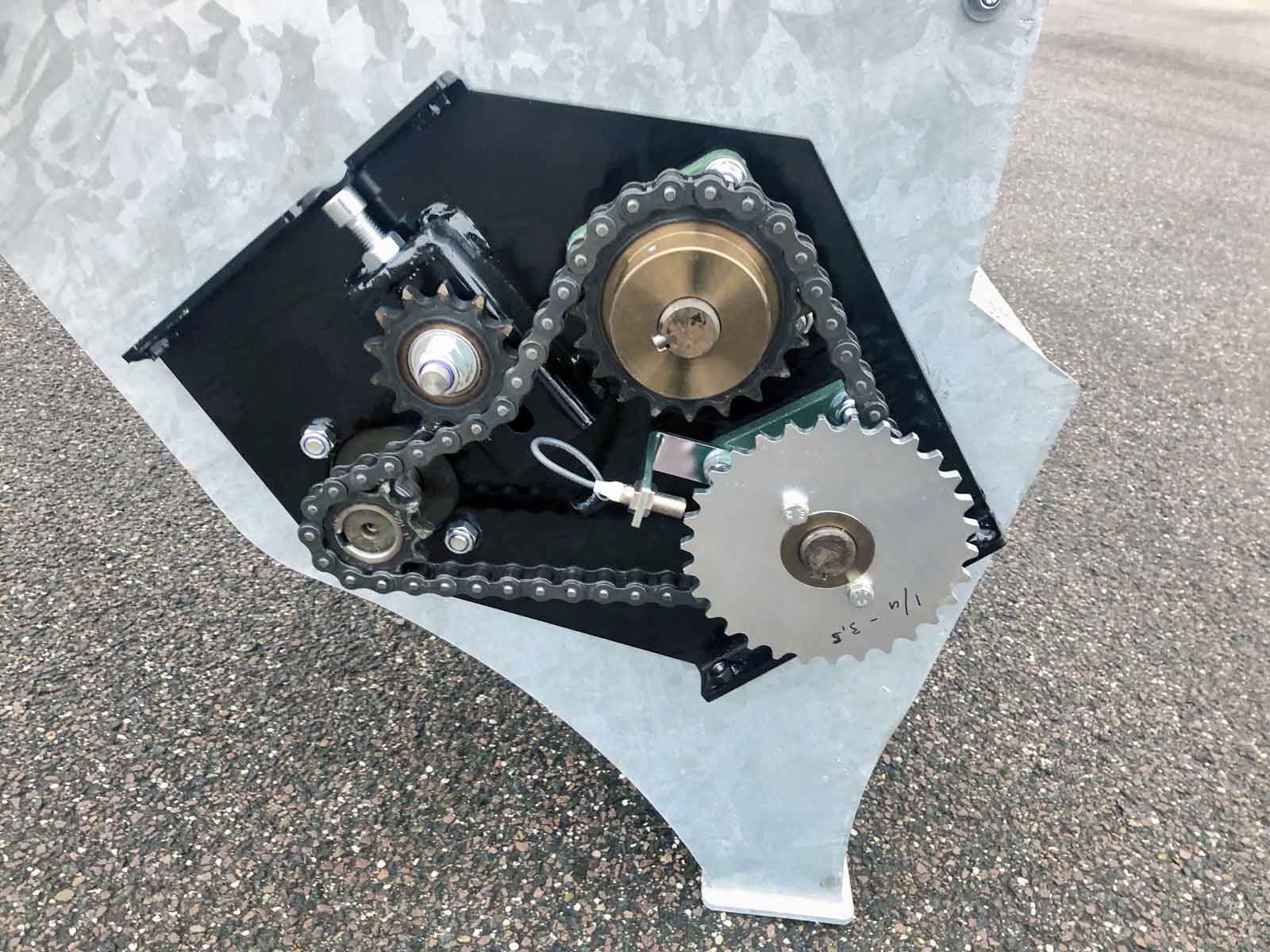

Chain drive

The powerful chain drive with ¾" chain and hardened gear wheel, as well as a stepless adjustable chain tension wheel ensure high reliability.

Bearings

Heavy-duty greasable flanged bearings ensure optimum operation of both the auger and agitators.

Oil engine

The powerful 250 cc oil engine, to drive the auger and agitator via the solid chain drive, ensures a quick start-up of the machine. The oil engine is well protected behind the guard under the machine.

Agitators

The agitators with angled blades provide optimum agitation of the material, creating an even flow of material to the auger.

Suspension, bolts on

All suspensions are bolted to the machine and you can choose between the many different options. (See optional extras).

Tarpaulin

A tarpaulin can be fitted to the spreader box to keep the material dry while working with the machine. (See optional extras).

Removed tarpaulin

The tarpaulin is easily unrolled and stored in the 4 holders at the rear while the machine is being filled with material.

Auger sensor

The spreader is as standard prepared for the installation of an auger sensor if you choose the electric control item no. 3708. (See optional extras).

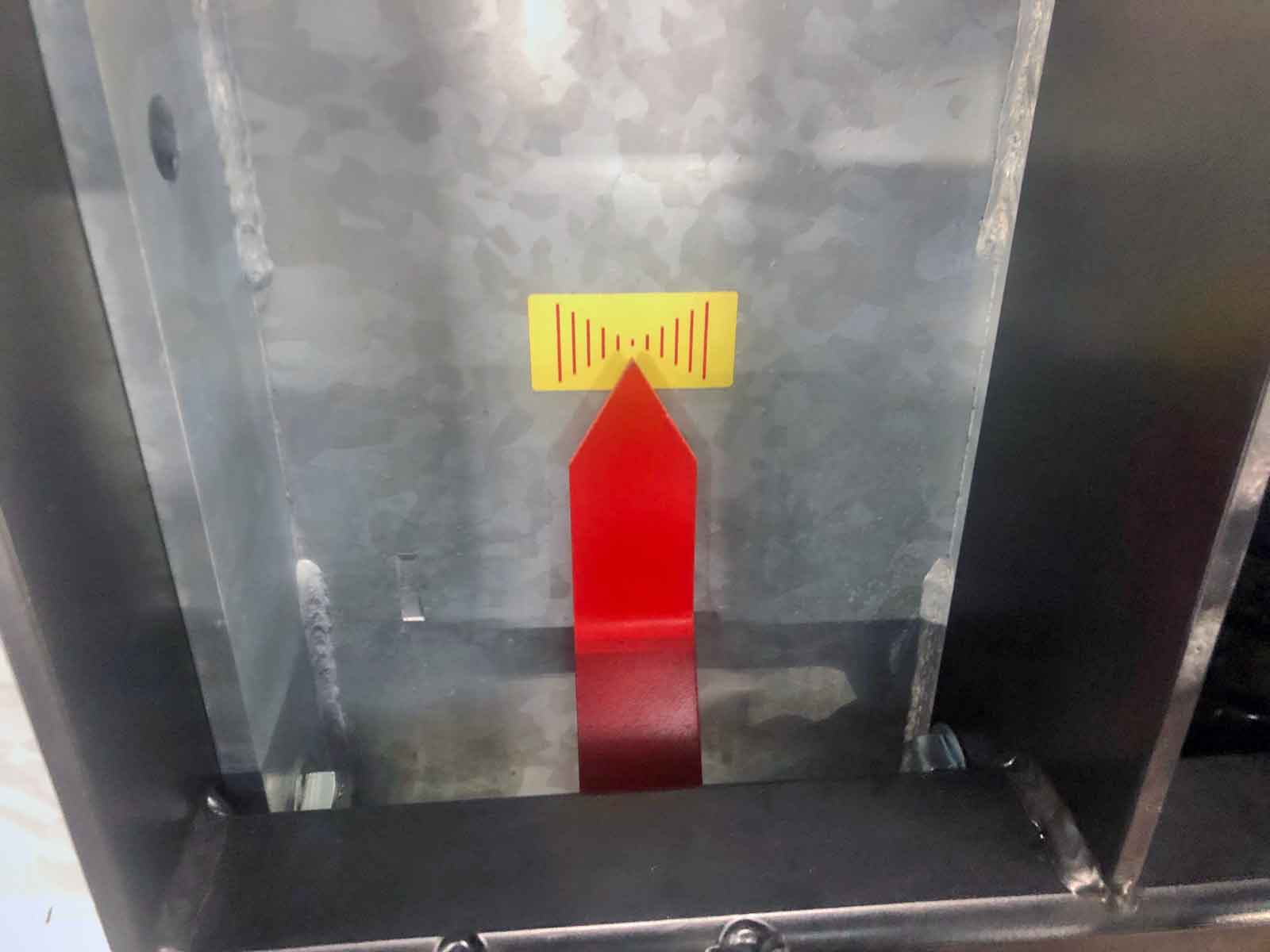

Shield

All parts of the shield at the bottom of the spreader box are made of stainless steel and the opening of the shield can be manually adjusted from 1 cm to 10 cm opening depending on the material being spread.

Disc sensor

The spreader is as standard prepared for the installation of a disc sensor if you choose the electric control item no. 3708. (See optional extras).

Guard over the bearings

The guard over the flanged bearings provides good protection against impacts when working with the machine and also ensures a long service life.

Guard over the valve block

The large valve block is well protected at the top centre of the machine and covered by the guard to avoid dirt and debris in the valves.

Auger

The auger at the bottom of the machine has a progressive rise on the blades, which ensures that the machine can constantly get rid of the material being fed. The strong blades ensure a long life.

Spreader disc

The spreader disc is made of 100% stainless steel and is driven by a hydraulic motor, which is well protected. The 6 blades are bolted on and can be adjusted in 3 positions, at the same time the disc can be hydraulically turned to the right or left side to achieve the optimal spreading pattern.

Control box for electrical control

The black control box for the electrical control item no. 3708 (optional extras) is IP66 approved and is well protected behind the suspension under the valve block.

Support legs

Strong support legs in a 4-edged hollow profile ensure stable parking of the machine. The support legs are lifted up while working with the machine so that they are always on the machine.

Support foot

The sturdy support feet at the back of the machine on each side ensure that the machine stands stable even when loaded and that the disc does not touch the ground.

Valve block

The large powerful valve block ensures optimal operation of the machine and can be operated manually on the 2 red screws on the block. It is recommended to purchase electrical control item no. 3708, to get the maximum utilisation of the STS-1800GA.

Holder for shovel

Holder for excavator shovel is standard equipment on STS-1800GA

Optional extras:

Item No. 3708

Electrical control box with many features such as spread width, volume control, forward speed, booster function and connection of various accessories

(Watch the video).

Item No. 3720

Hydraulic loading cylinder with a bracket for mounting on 3-point suspension (item no. 3730)

Item No. 3730

3-point suspension cat. II bolts on.

Download PDF files

See our information material here, where you can also read it online, print or download the files.