Woodchipper PC-2700-PEC

Presentation

This tractor-mounted pellet woodchipper with a 360° console system can handle logs up to 27 cm in diameter. It is prepared for crane mounting to feed the machine. Your work is made easier by using, for example, a forestry crane. The two feed rollers are powered by the tractor’s hydraulics. The machine’s sturdy main frame provides a stable and reliable chipping process.

Each feed roller is driven by its own hydraulic motor, and the feed speed can be adjusted stepless as needed. Together with the rotation guard, this ensures optimal adjustment to the task at hand. The feed rollers are remote-controlled and can be operated from the same control station as, for example, a mounted forestry crane.

Top-Quality Wood Chips

With the pellet woodchipper, you can produce the Danish trademark-registered PC-FLIS®, which is completely free from splinters and lumps, making the chips ideal for, for example, heating.

With the correct adjustment of the knife's cutting height and selection of the hole size in the sieve, you can adapt PC-FLIS® to numerous purposes, such as animal bedding, uniform mulch, a replacement for wood pellets, and other tasks where it is critical that the chips are completely free from splinters and lumps.

Only chips produced on a PC pellet woodchipper may be called PC-FLIS®.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Technical Data

| Technical Data | PC-2700-PEC |

|---|---|

| Type | Pellet woodchipper with 360° sieve |

| Wood Diameter (max.) | Ø27 cm |

| PTO Revolutions | 540 / 1,000 rpm |

| Power Requirement at 540 rpm | Max. 60 kW / 80 hp |

| Power Requirement at 1,000 rpm | Max. 112 kW / 150 hp |

| Spline on Main Shaft | 1 3/4” x Z6 |

| Net Weight | 1,500 kg |

| Mounting | 3-point hitch on tractor |

| Hydraulics | From tractor |

| Number of Feed Rollers | 2 |

| Feed Roller Torque | Up to 1,096 Nm |

| Rotor Weight (total) | Approx. 380 kg |

| Capacity (*) | 30 m³ per hour |

| Crane Mounting Option | Yes |

| Rotation Guard | Yes, standard |

| (*) Capacity depends on factors such as knife settings, available horsepower, wood condition, and rotor speed. |

Details

3-Point Hitch

The sturdy 3-point hitch ensures secure mounting on the tractor.

Emergency Stop

The visible emergency stop button is used for quick stops in urgent situations.

Rotating Chute

The chute can be rotated in selected intervals via a stainless-steel handle.

Adjustable Top Flap

The top flap holder allows you to set the desired exit angle of the chip stream

Warning Symbols

Symbols increase safety awareness when using the machine.

Remote Control of Feed Rollers

The rotation direction of the rollers can be reversed (in/out), started, and stopped with a remote control.

Gas Cylinder

The gas cylinder helps hold the lid of the rotor housing in the open position during service.

Handle

The handle on the rotor housing lid makes it easy to open and close the lid.

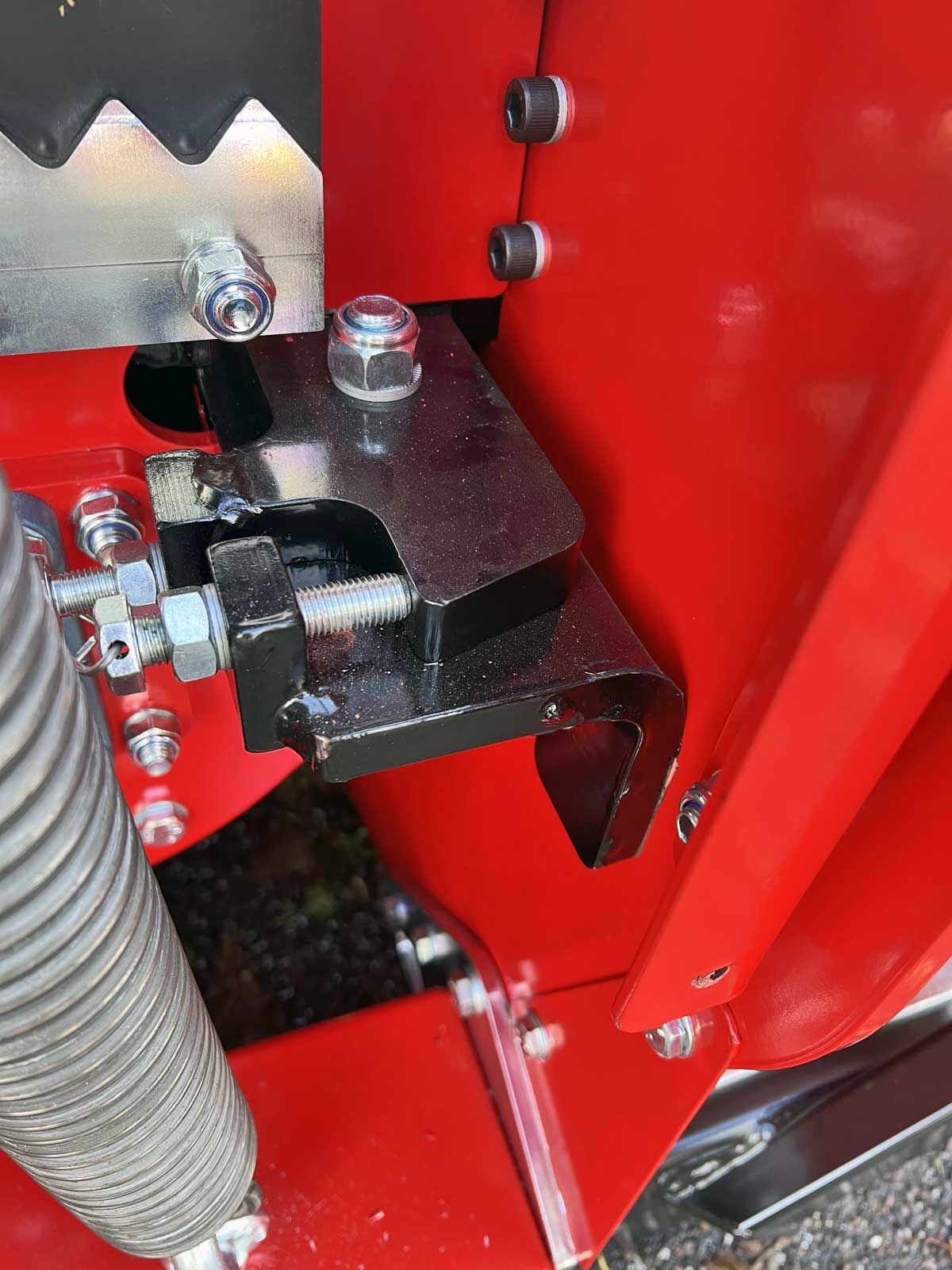

Rubber Mounting

The heavy-duty rubber mounting dampens vibrations.

Adjustment Valve

The adjustment valve ensures consistent hydraulic pressure to the feed rollers.

Chipping Wheel

The massive chipping wheel is the foundation for an efficient work process.

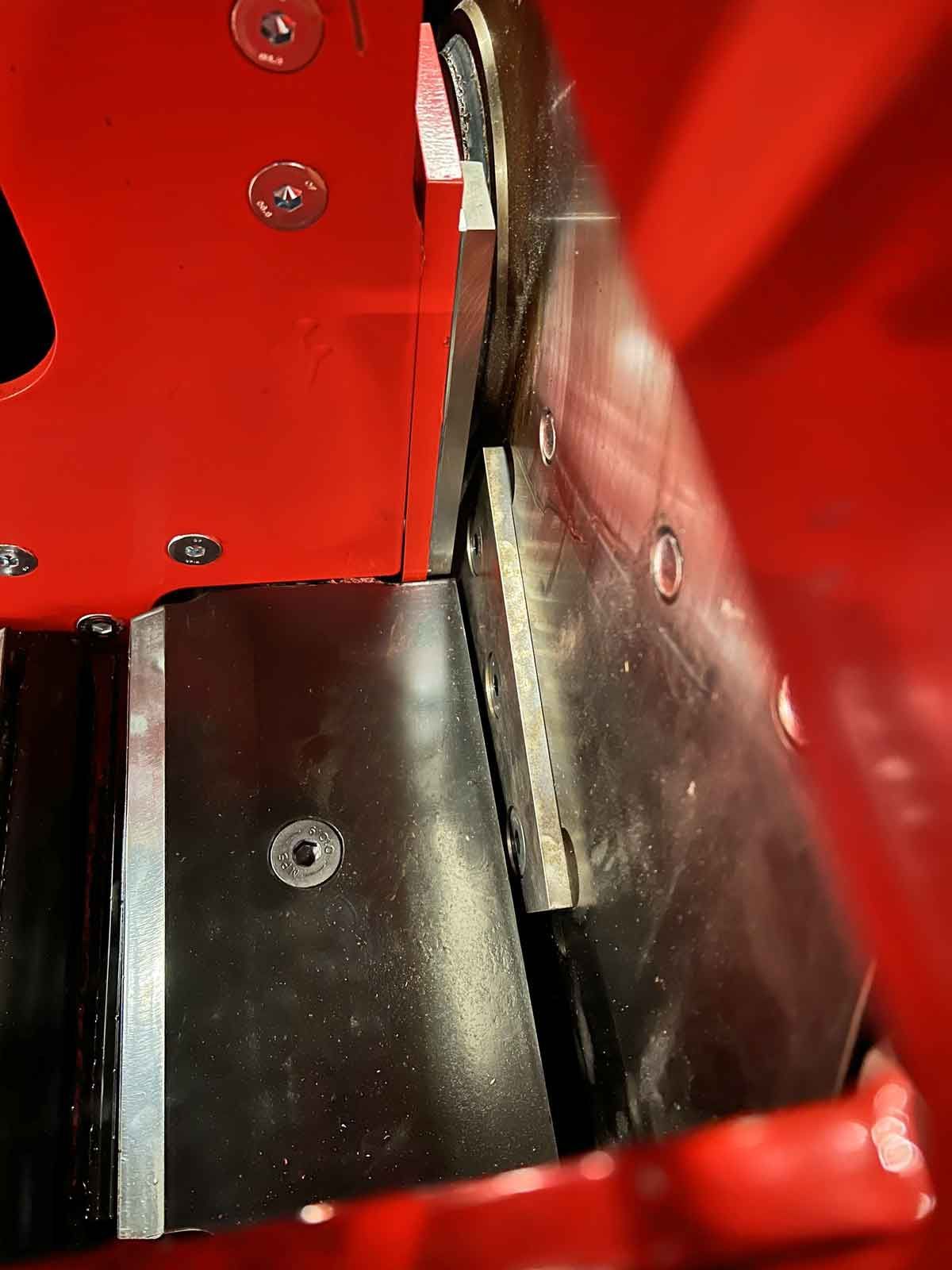

Chipping Knives

The sharp and robust chipping knives are mounted on the chipping wheel.

Hydraulic Valve

The hydraulic valve delivers consistent pressure to the feed rollers.

Feed Roller Opener Rod

The rod is used to open access to the feed rollers. The rod is stored on the machine stand for easy accessibility.

Sturdy Rotor Housing

The solid construction of the rotor housing ensures an efficient work area for the chipping wheel and knives.

Crane Flange

The crane flange is designed for mounting a crane used for feeding the machine.

Service Lid

The rotor housing lid is secured with solid bolts, which can be easily removed during maintenance.

Stainless Steel Lock

The lock secures the lid for the feed rollers and is released when the lid needs to be opened.

Counter Blade, Bottom

The bottom counter blade acts as a support for the material, ensuring that the chips are cut to the desired size.

Bottom Counter Blade Adjustment

The bottom counter blade in the rotor housing can be fine-tuned to ensure consistent processing of material.

Counter Blade, Side

The side counter blade acts as a support for the material, ensuring that the chips are cut to the desired size.

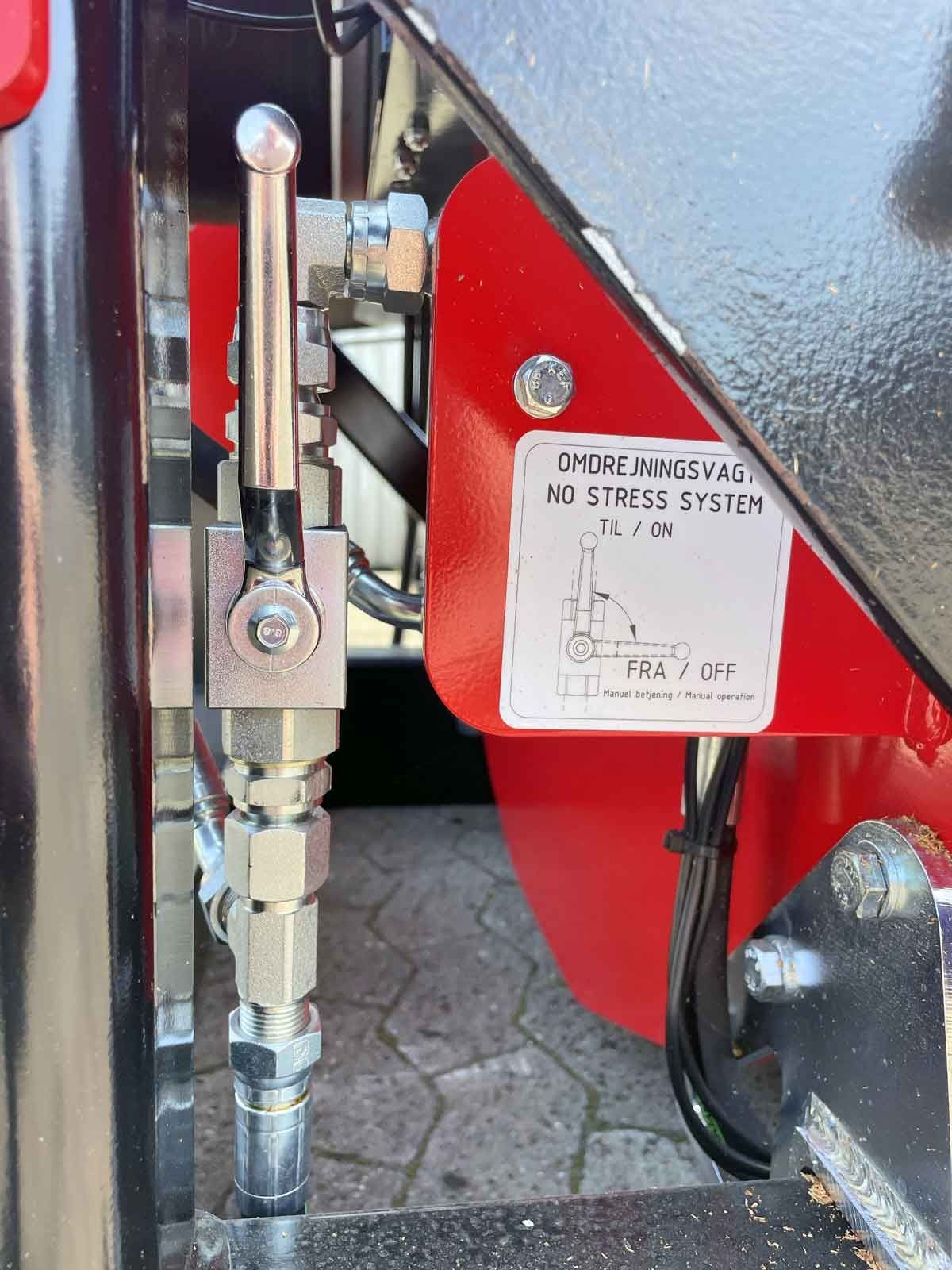

No Stress System, Adjustment

The handle allows you to choose between the automatic No Stress System or manual control. The No Stress System ensures an automatic adjustment of the amount of wood passing through the machine, so it is not overloaded.

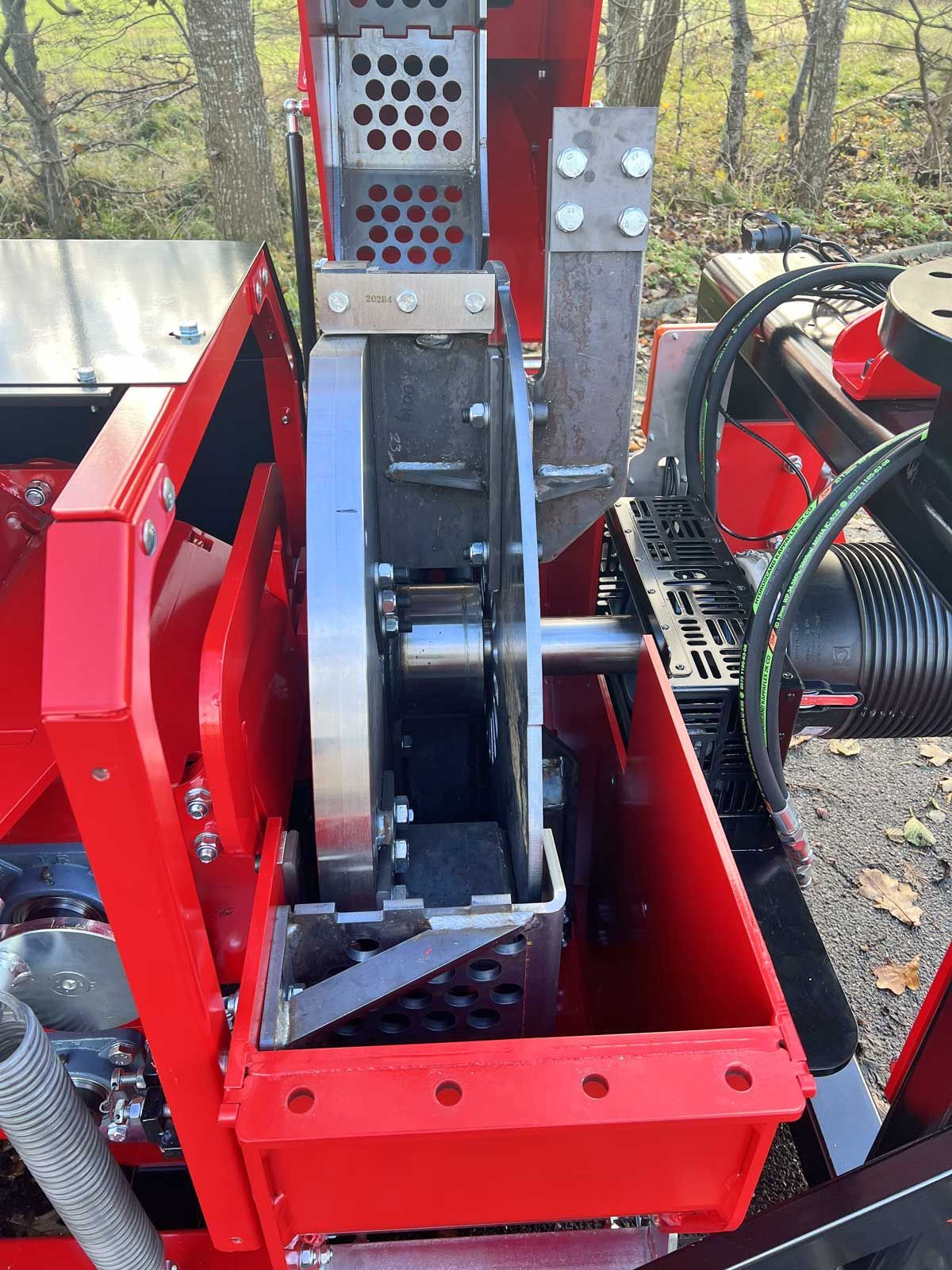

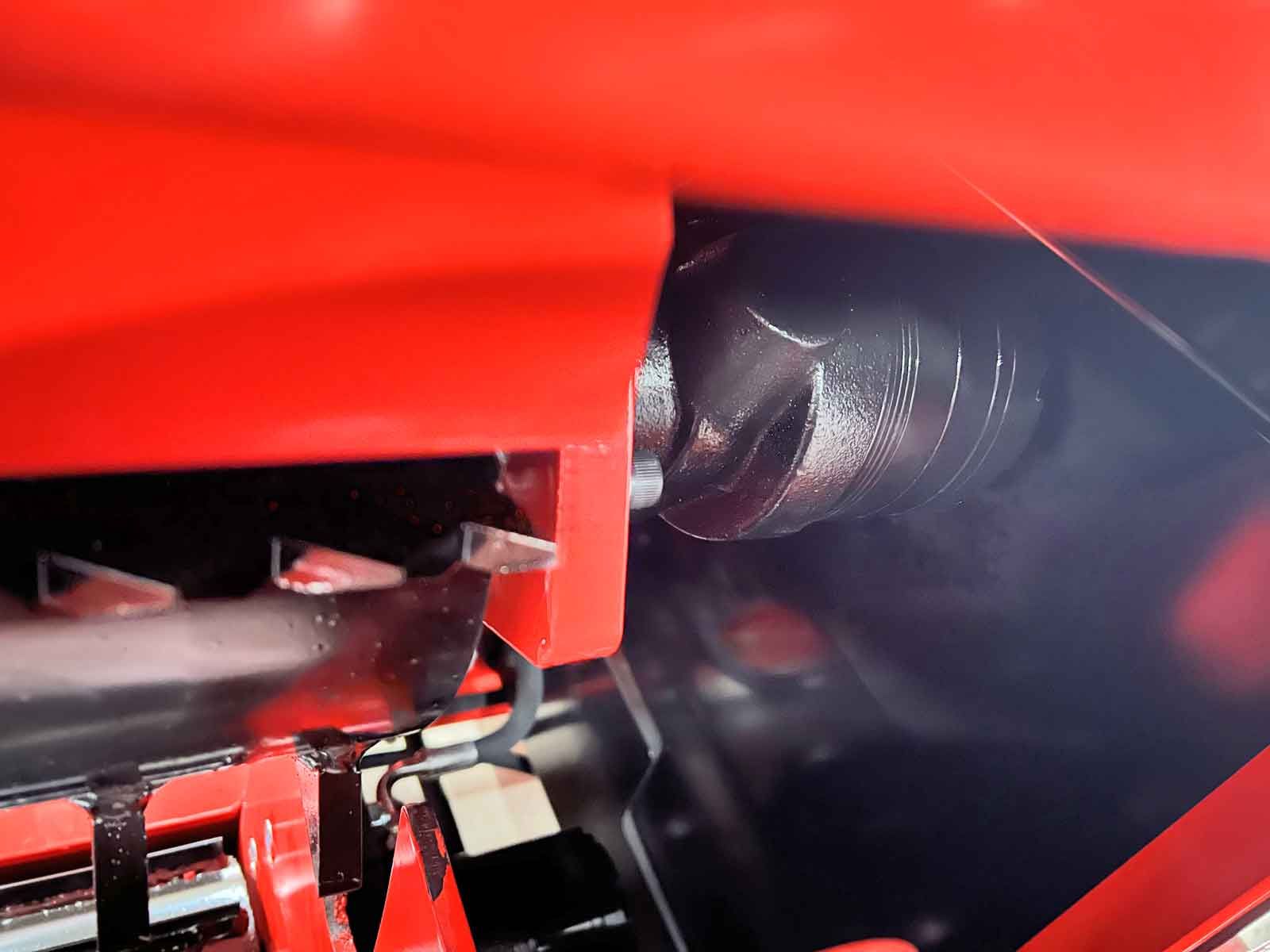

Oil Motor

The feed rollers are powered by a robust oil motor.

Towing Hitch

The tow bar allows a trailer to be hitched to the woodchipper. A bolt with a split pin is used to prevent the trailer from loosening when driving on uneven terrain.

PC-FLIS®

The pellet woodchipper PC-2700-PEC, with the patented 360° console system, produces PC-FLIS® without splinters and lumps. The console guarantees that the chips are free from splinters and lumps and thus meet strict quality standards. Only chips produced on a PC pellet woodchipper may be named PC-FLIS®.

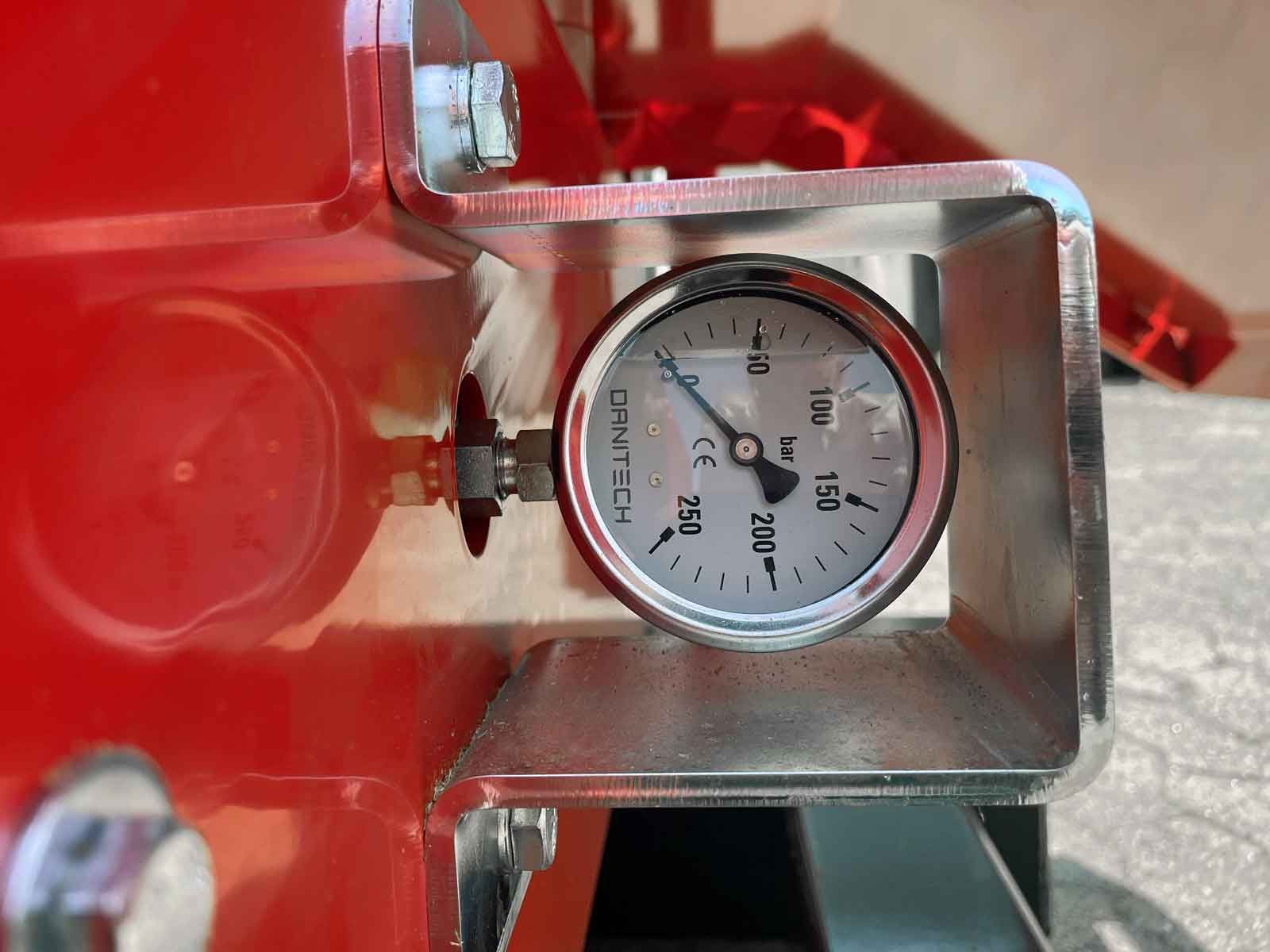

Pressure Gauge

The pressure gauge shows the current hydraulic pressure.

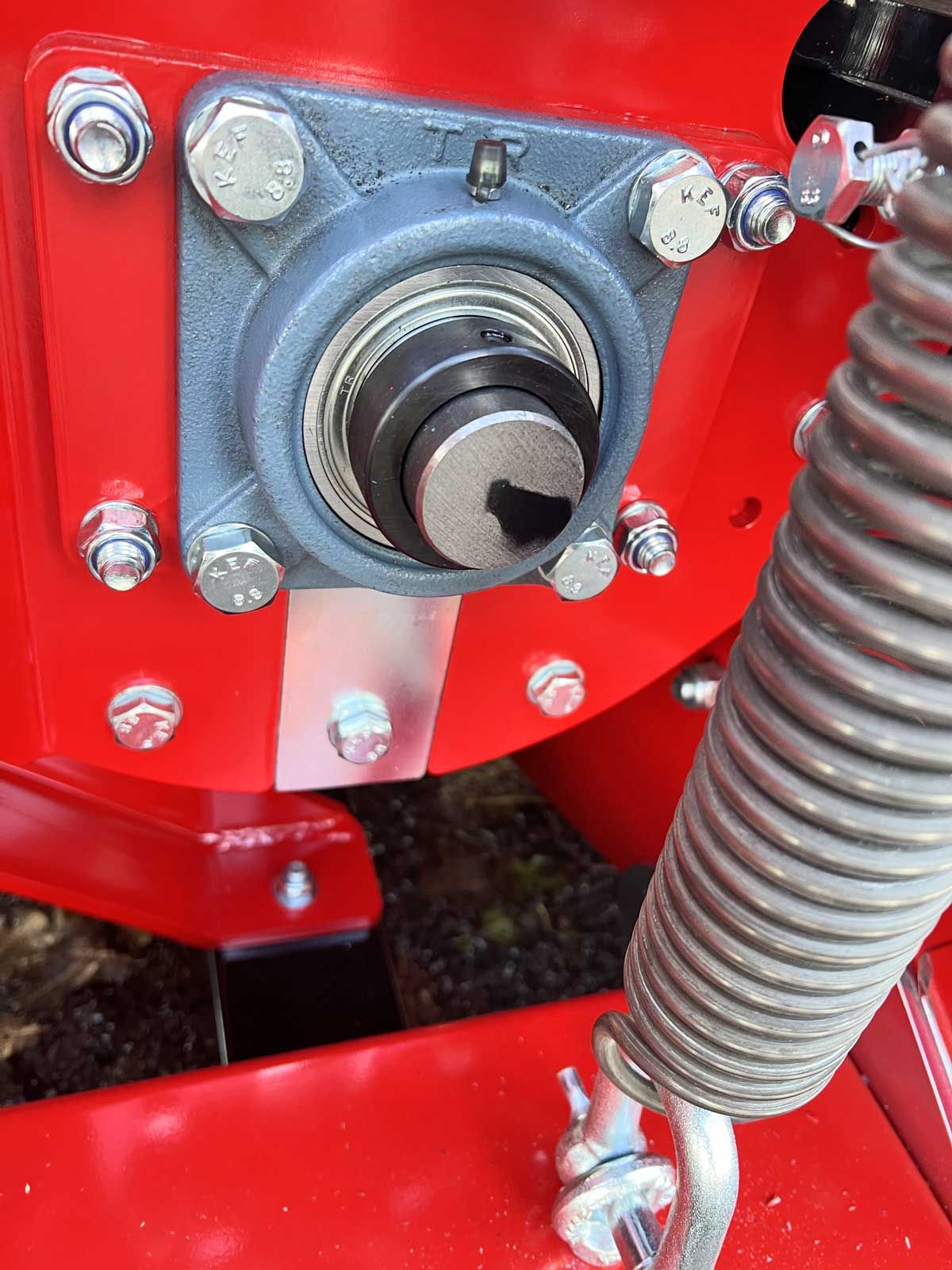

Steel Bearing

The rotor is mounted on a heavy-duty steel bearing designed to handle large loads during operation.

PTO Shield

The large, solid PTO shield provides optimal protection. It can be easily removed with two clamps for easier access during power transfer assembly.

PTO Holder

The PTO holder in stainless steel is used for protective storage when the woodchipper is not in use.

Rotor

The total rotor weight of approximately 380 kg ensures smooth operation. The rotor's inertia helps chip the wood without the tractor's power requirement being of critical importance.

Console (optional)

The console (optional) is delivered with the desired chip sizes. The holes in the console determine the size and quality of the chips. The console is constructed of heavy-duty stainless steel for demanding tasks and long durability.

Console Knives

The console knives further shred the wood material until it can pass through the console holes.

Rollers, Open

Easy access to rollers and feed during service.

Rotor Lock Bolt Mounting

The lock bolt is a safety measure. It is mounted into the side of the rotor to prevent it from rotating unintentionally during service or inspection.

Rotor Lock Bolt Storage

The lock bolt is stored in the holder when in use, during transport, or in storage.

Spring on Feed Rollers

The heavy-duty spring holds the feed rollers in the optimal working position.

Mounted Crane

The woodchipper is an effective work machine when fully equipped with a crane, which is additional equipment.

Horizontal Feed

The feed consists of two horizontally placed feed rollers, providing the strongest construction and best grip on the wood. The adjustable feed speed, which the wood is fed into the woodchipper, can be steplessly adjusted to achieve more even and adapted operation.

Accessories

Item No. 11417110

PTO shaft for PC-2700

Download PDF-filer

See our information materials here, where you can also read them online, print, or download the file.