Chain Mower FKR-152

Presentation

Customer requests, especially from the Scandinavian market, have once again created a unique product based on experience from existing, proven chain mower models. The model has been developed in response to requests from customers to develop a chain mower that can clear both centre and roadside verges without having to change machines.

Our development and production departments have worked hard to meet this requirement, as there is apparently no machine that can do both. The new FKR-152 chain mower with swivel arms is the machine to fill this gap.

Combination of functions creates a flexible solution

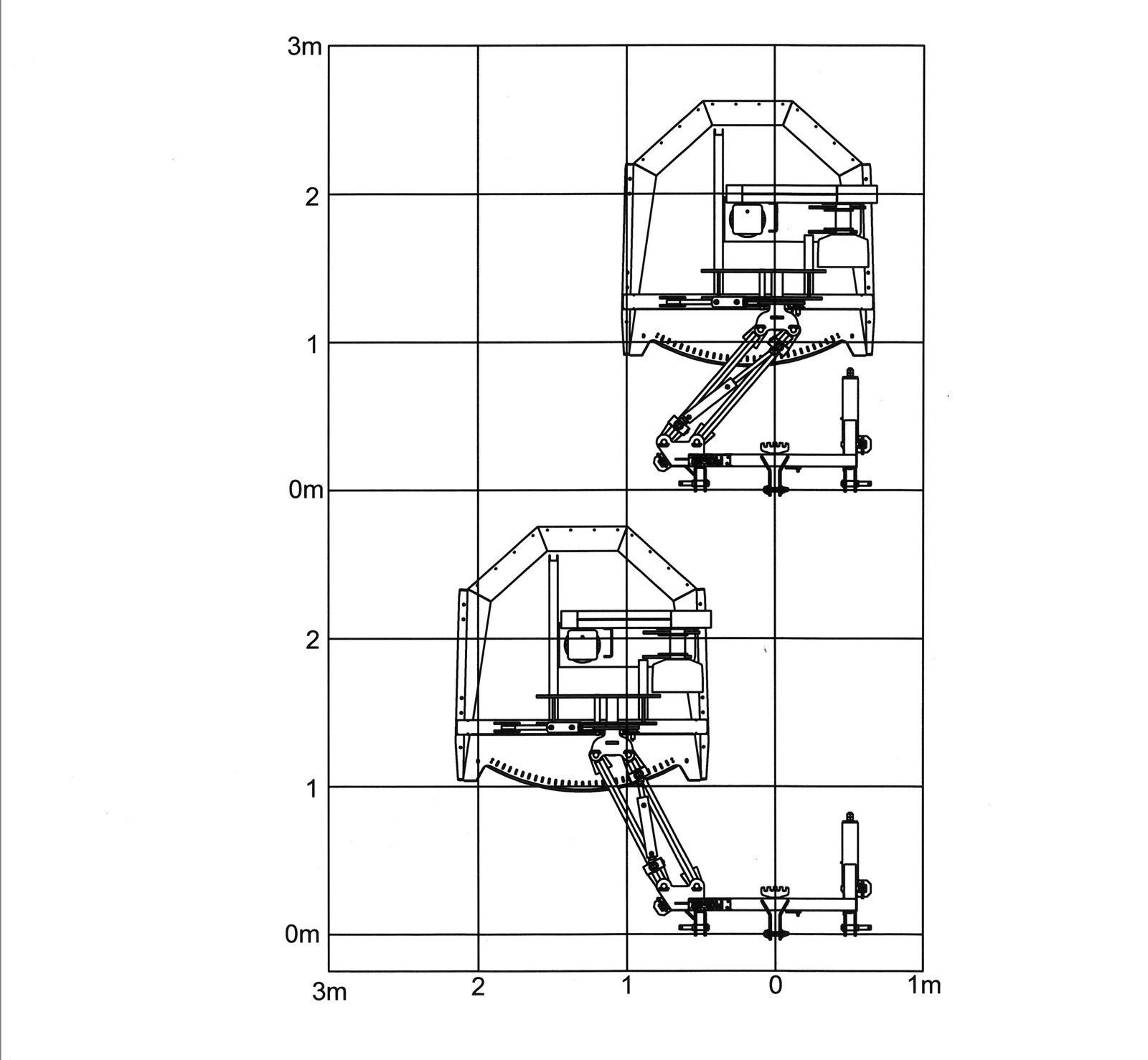

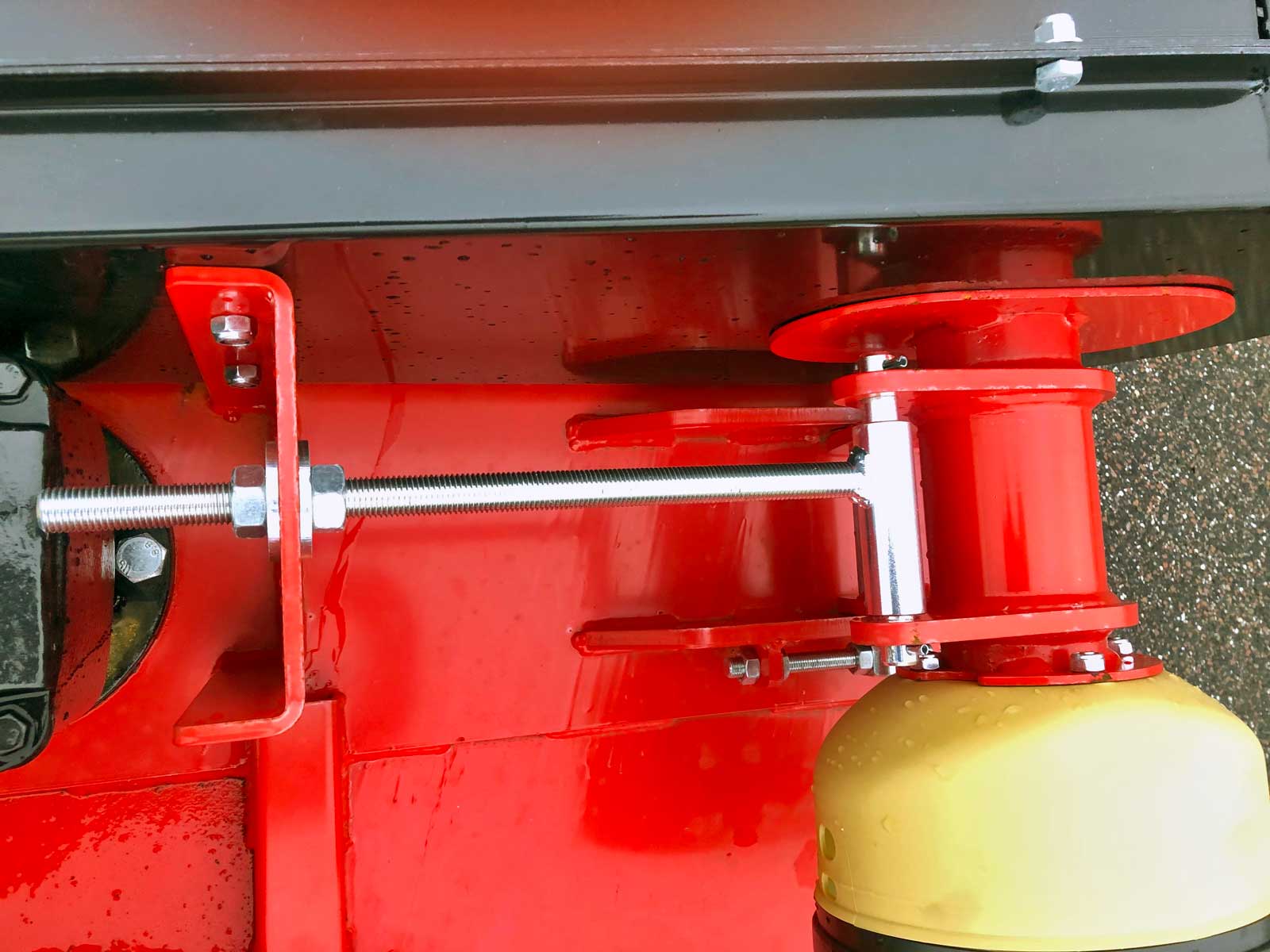

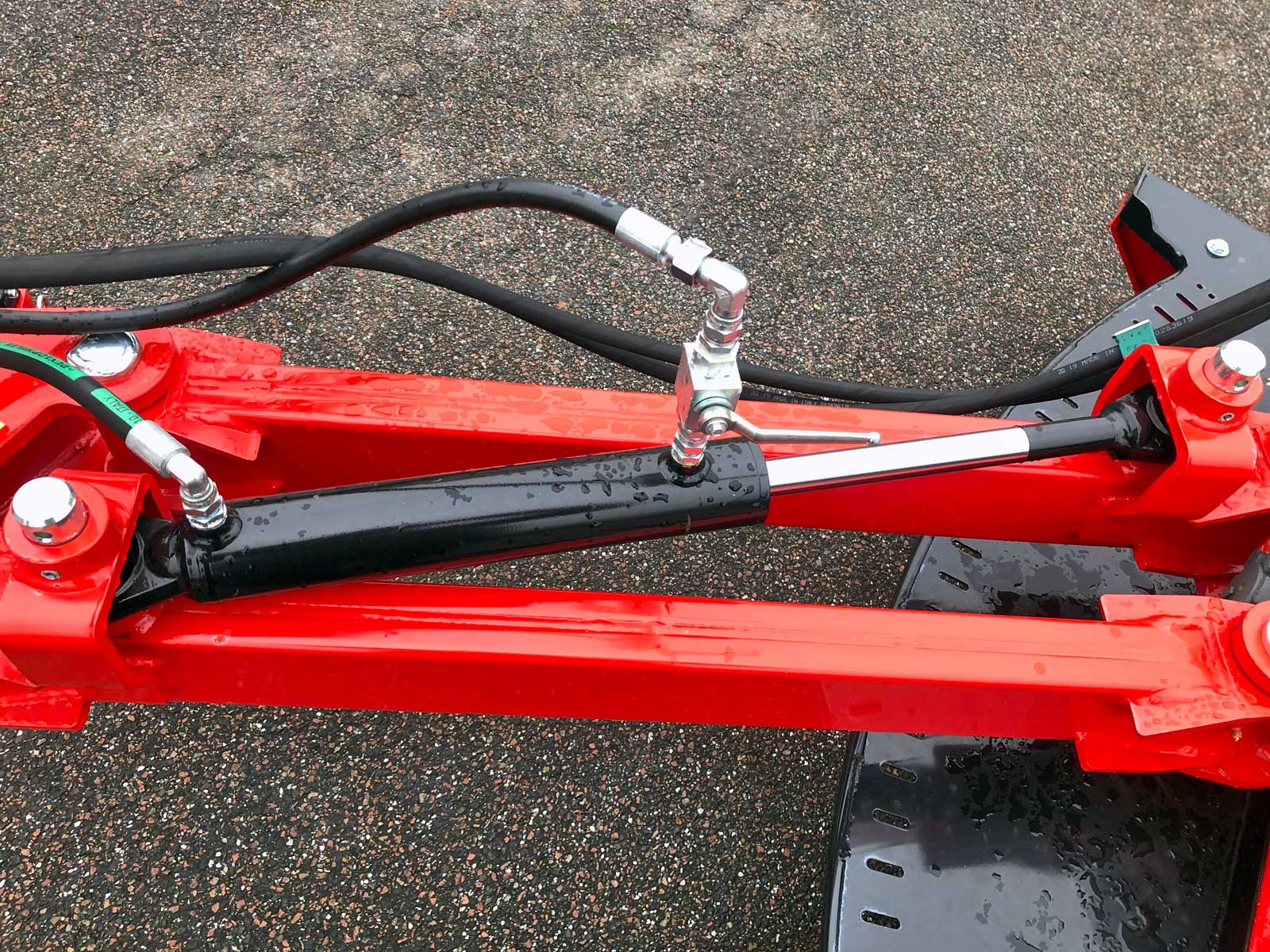

The FKR-152 chain mower has a built-in combination of features that make it very flexible. With hydraulic swivel arms, the machine can be pushed one metre to the side in relation to the centre position. This enables the machine to carry out both the clearing of the central verge when it is positioned centrally and the roadside verge when it is turned sideways.

In addition, the chain cutting shield itself is hydraulically tiltable at an angle of up to 30°, so it can automatically adapt to the terrain. The machine is therefore very suitable for field and gravel roads, narrow forest roads and paths through dense vegetation and changing landscape.

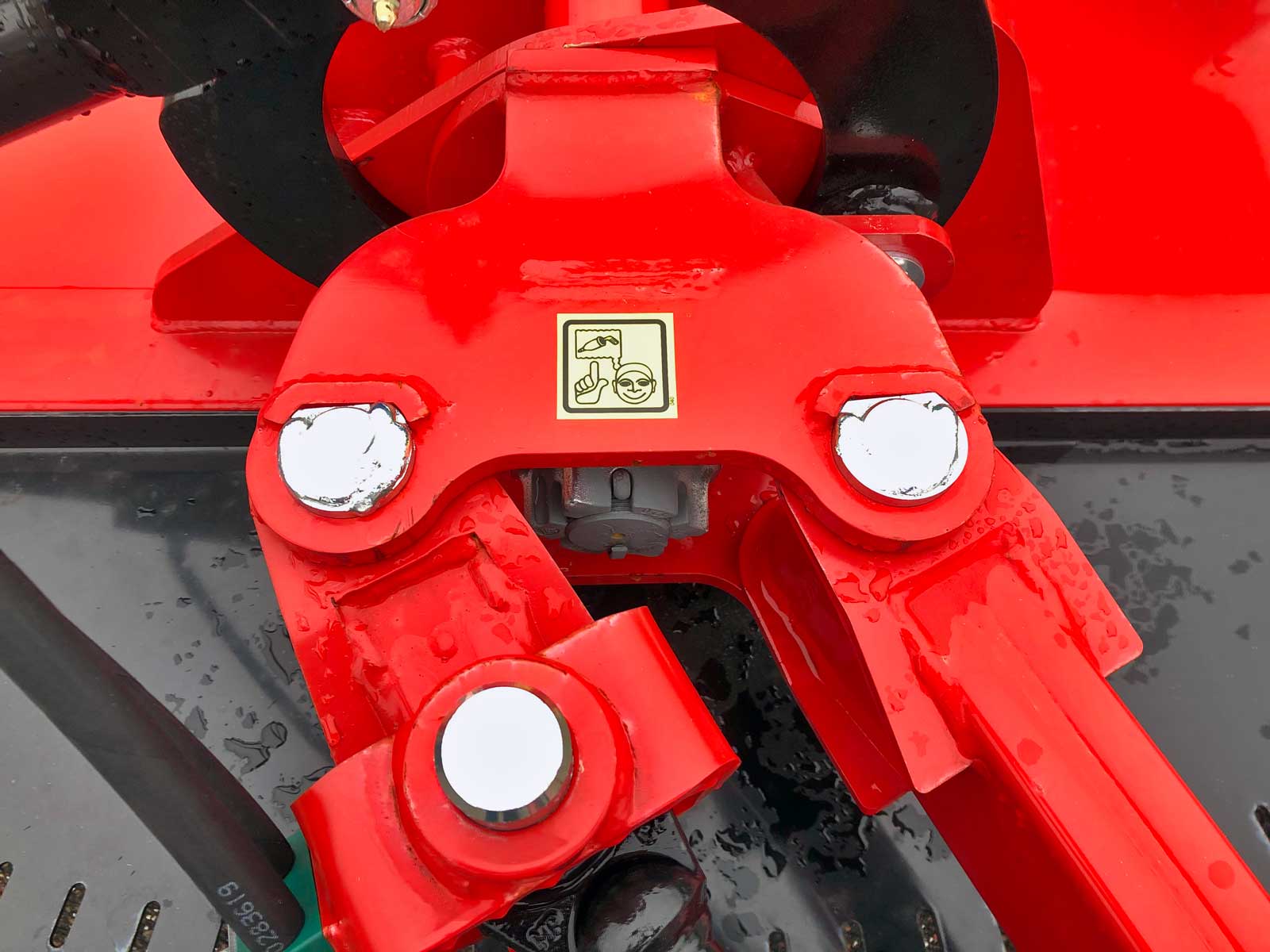

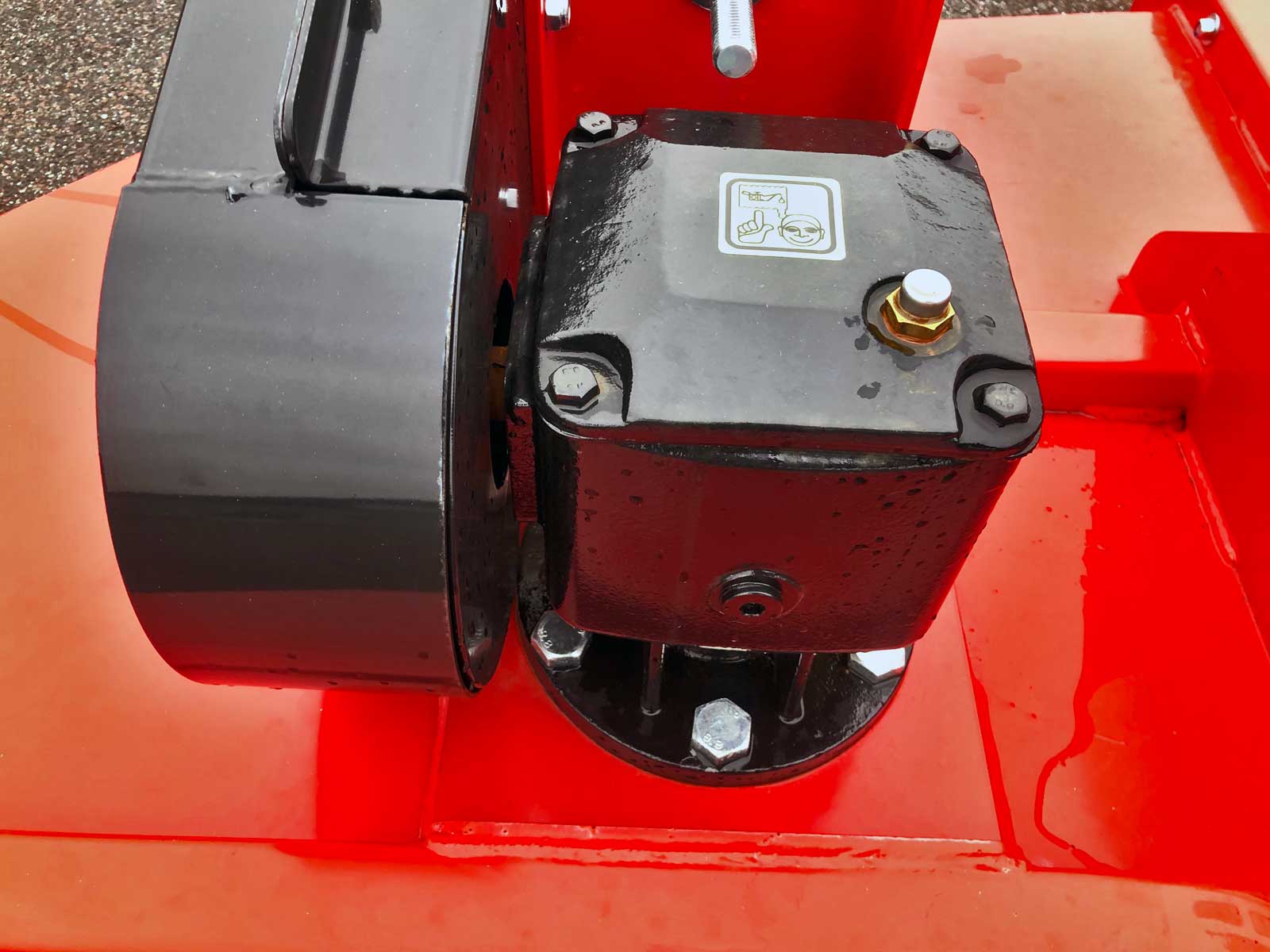

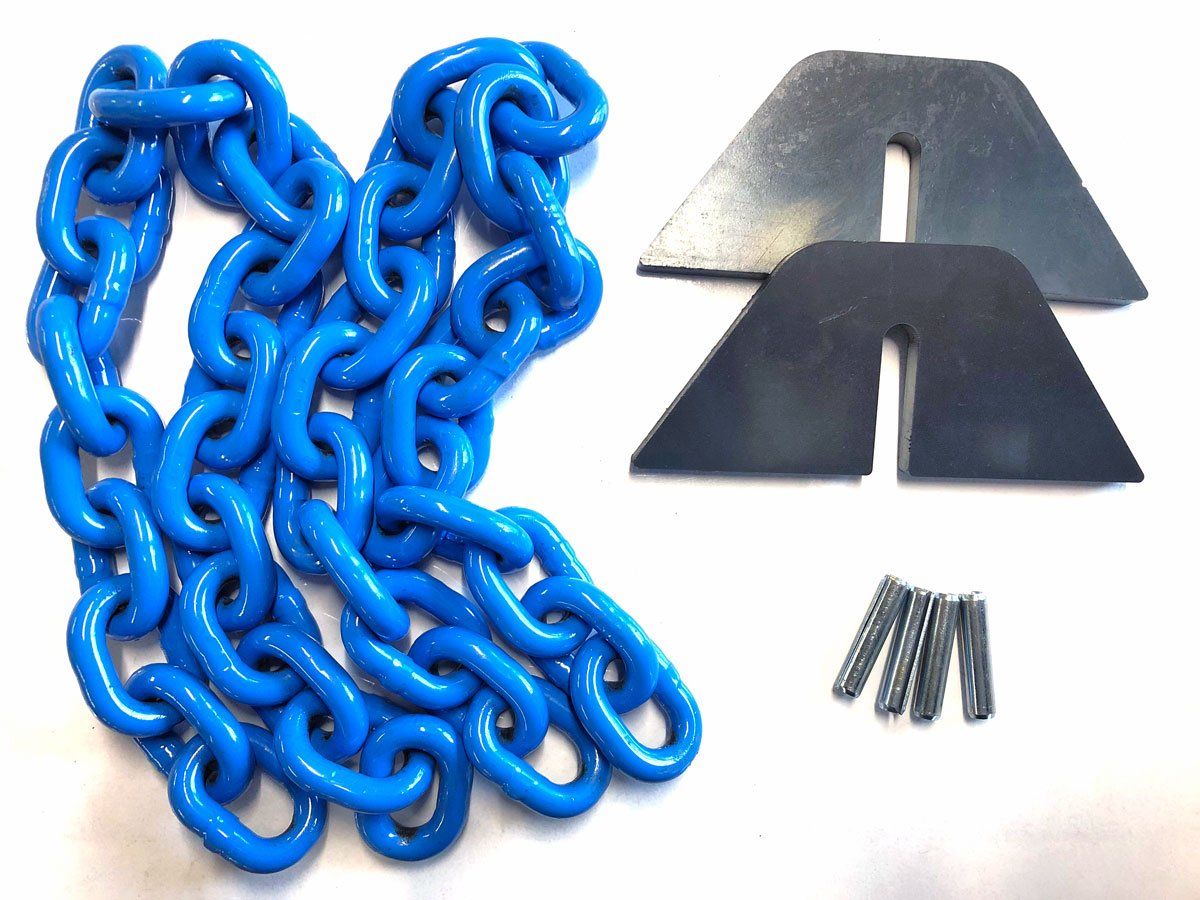

Clearing vegetation places high demands on quality and durability, as there are often stones and other things hidden in the tall grass and many leaves. Therefore, the model has 2 steel chains in G100 quality. Power is transmitted by a three-track powerbelt belt drive, which, in addition to transmitting high power to the work, also absorbs vibrations coming from the chains.

The wear shoes are made of Hardox 500 metal and the main frame is built of Domex 420 high-strength steel. In addition, a reinforced rubber cover is fitted to the back to protect against flying objects.

Technical data:

| Technical data: | FKR-152 |

|---|---|

| Working width | 150 cm |

| Chains mm/number | 10/13 mm / 2 pcs. |

| PTO drive | Yes |

| PTO speed | 540 rpm |

| Working speed | 0-20 km/h |

| Offset adjustment | 115 cm |

| Weight | 675 kg |

Download PDF files re. Chain Mower FKR-152

See our information material here, where you can also read it online, print or download the file.