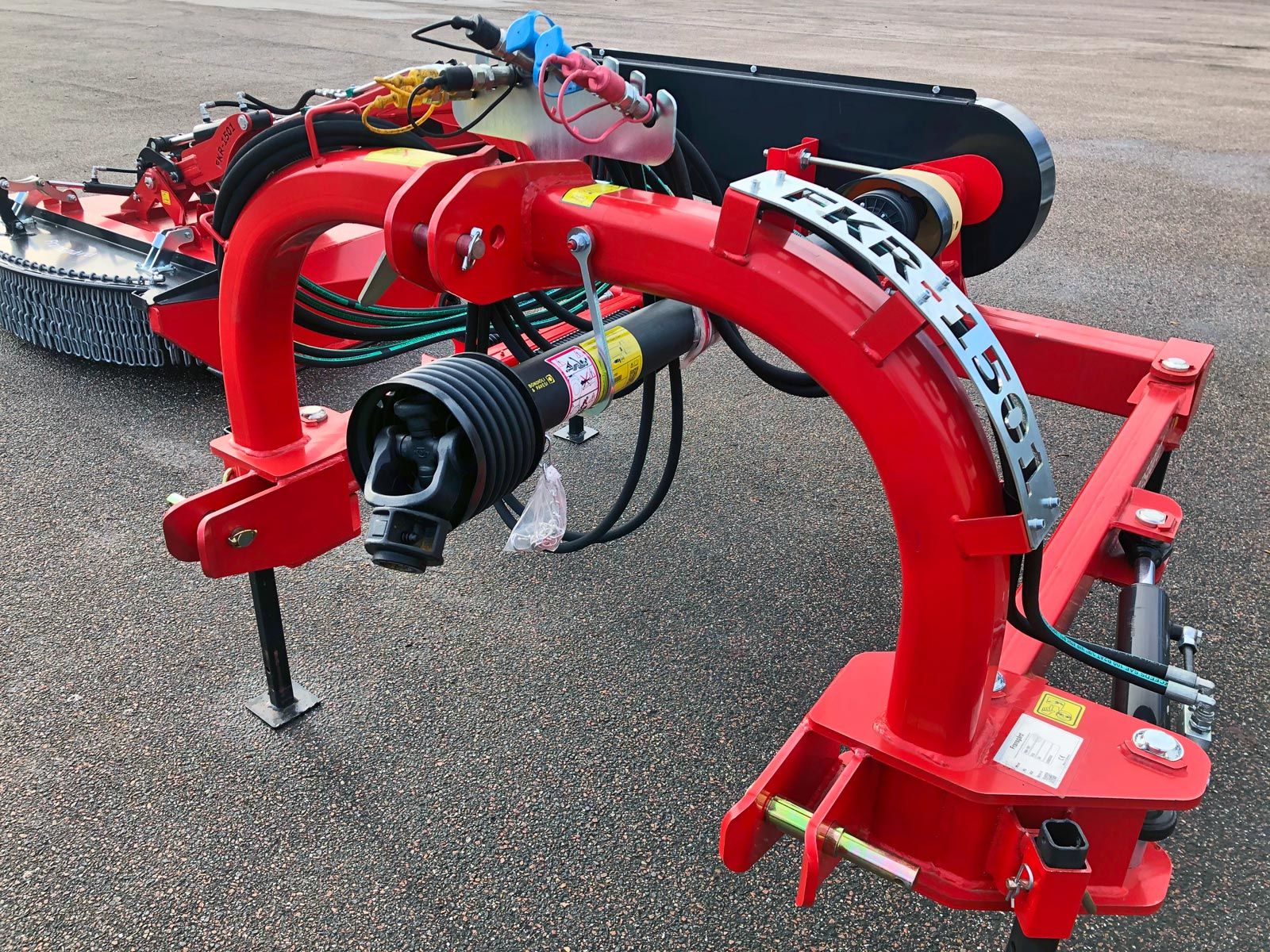

Chain Mower FKR-1501

Presentation

Fransgård's new chain mower has been developed as a robust construction with many unique details that provide high flexibility and allow it to work efficiently in various demanding environments.

The mulcher can work in many different materials - everything from heavy grass to very dense shrubbery and smaller self-planted trees along forest roads. It can also be used for cutting hedges and branches hanging over roads.

Large working area with many technical features

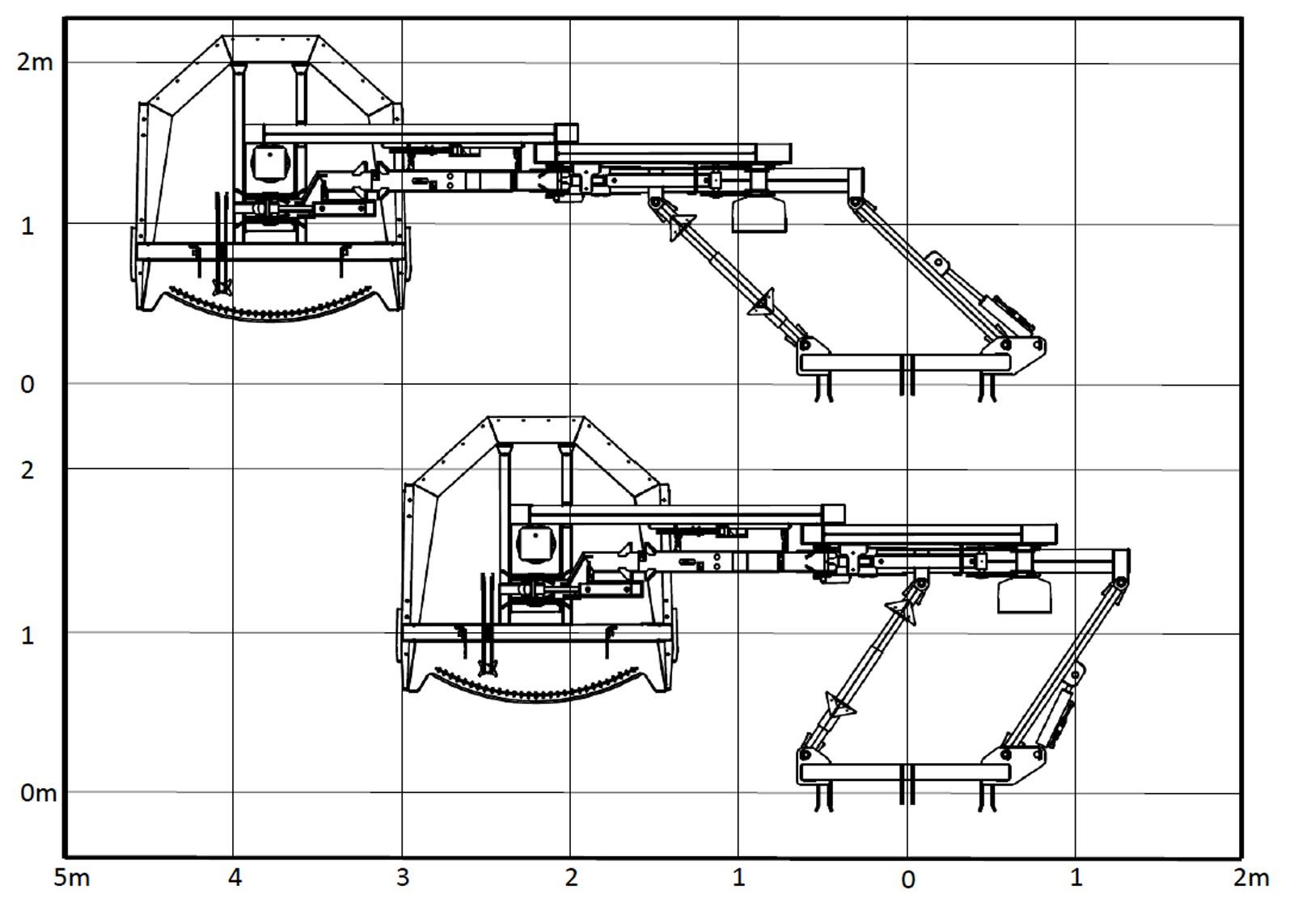

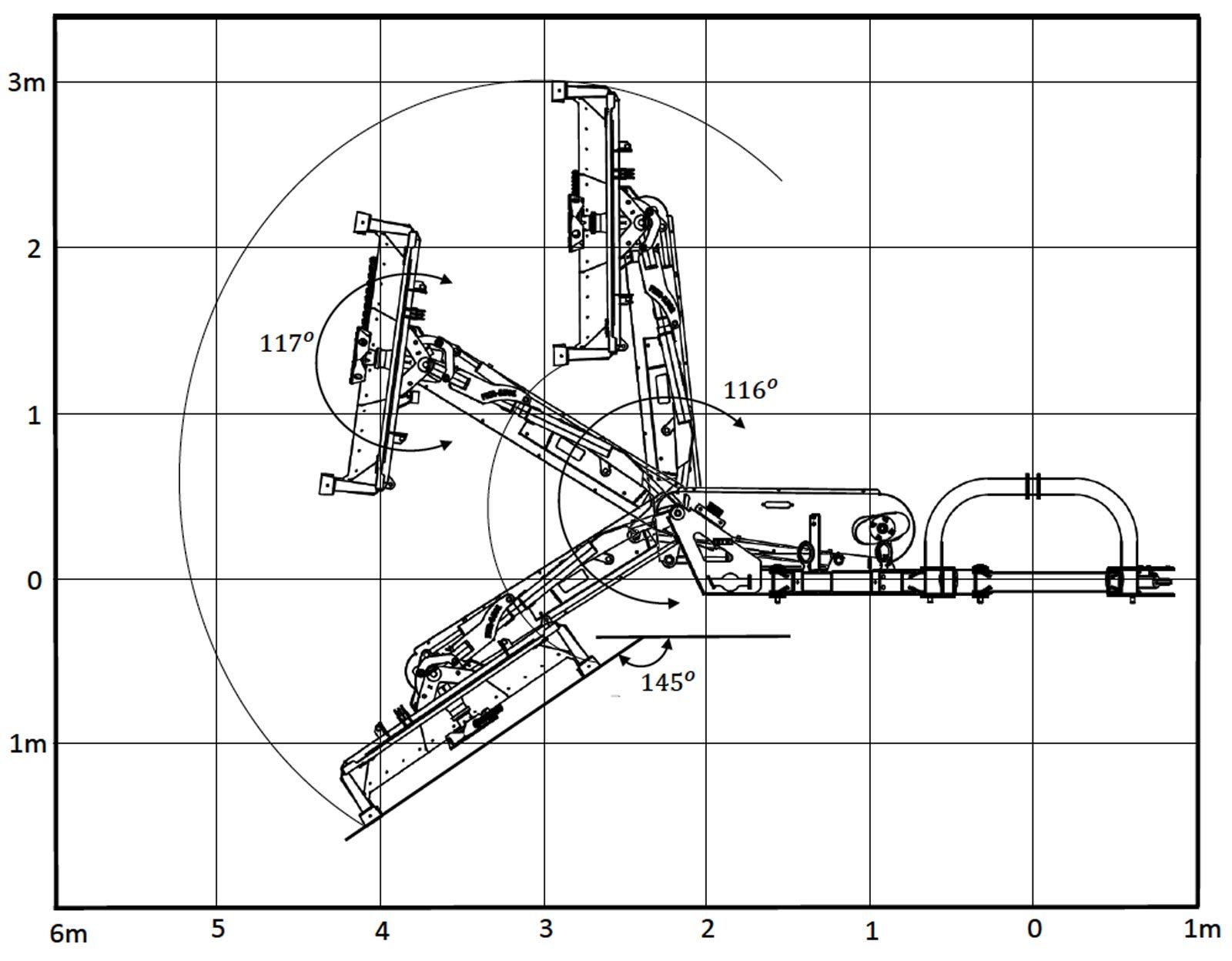

The machine works up to 4.55 m from the centre of the tractor and can operate in a vertical position from 0-4 m in height and 35° downwards, where the flexible head allows you to work on both sides of a ditch from the same position (see the working area chart). The machine has an offset adjustment of 1.5 m.

The hydraulic cylinder for the mowing head can advantageously be in the floating position during work, as the machine then follows the ground perfectly. The machine is driven via a PTO axle and 2 powerful 3-track powerbelts with a double tightening function on the long belt. The drive line combined with PTO drive and 3-track powerbelt provides optimal operation and ensures minimal wear on the machine - even in the harshest environments.

The transport width is 2.5 m and the machine requires a tractor with a weight of 5 tonnes. Collision protection is standard equipment.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Technical data:

| Model: | FKR-1501 |

|---|---|

| Working width | 150 cm |

| Transport width | 250 cm |

| Offset adjustment | 150 cm |

| Range max. | 455 cm (from the centre of the tractor) |

| Working area down | 35° |

| Working area up | 90° (height 0-4 metres) |

| Number of chains | 2 |

| Chain dimensions | 10 or 13 mm |

| Chain quality | G100 |

| Hydraulic connectors | 3 double |

| Wear shoe | Standard |

| Power take-off (PTO) | 540 rpm |

| Tractor weight | min. 5 tonnes |

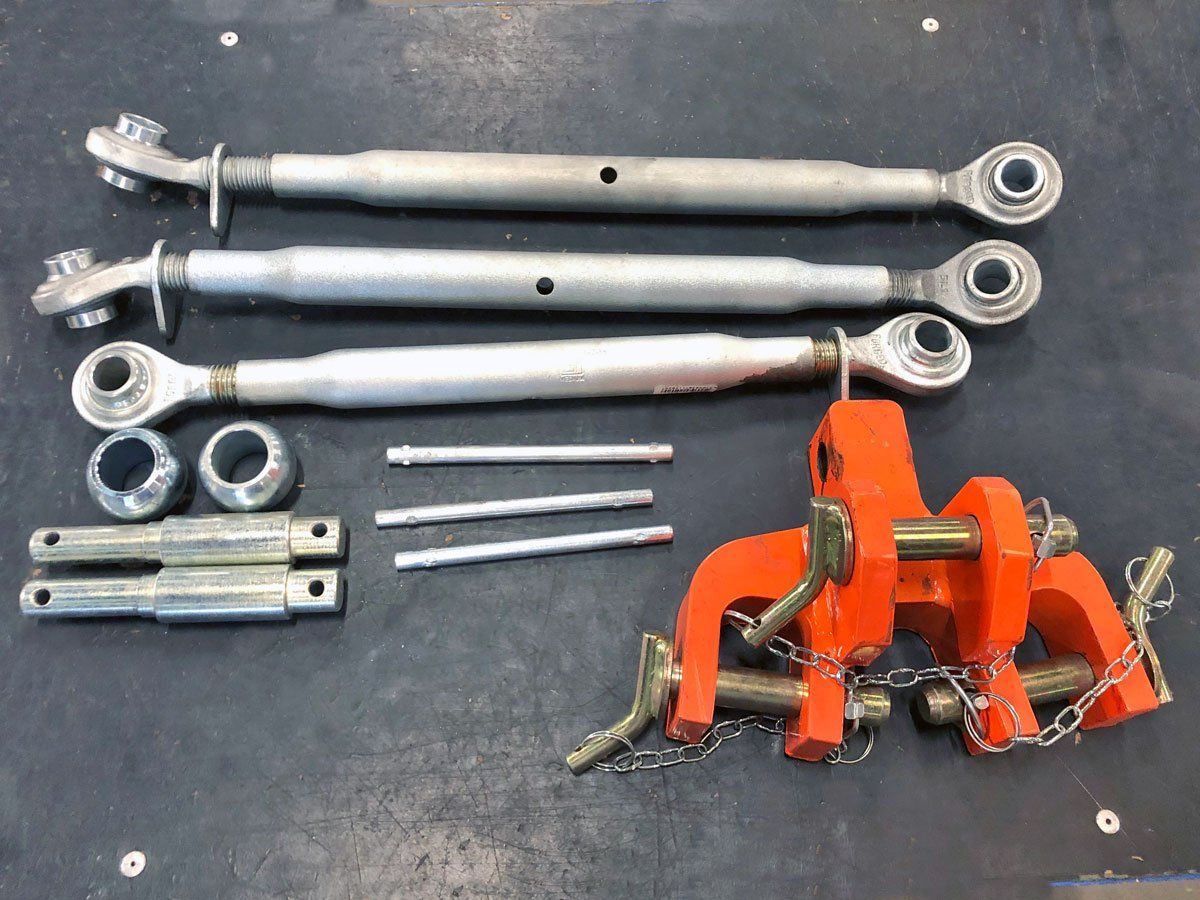

| 3-point suspension | Cat III |

| Weight | 910 kg |

Details:

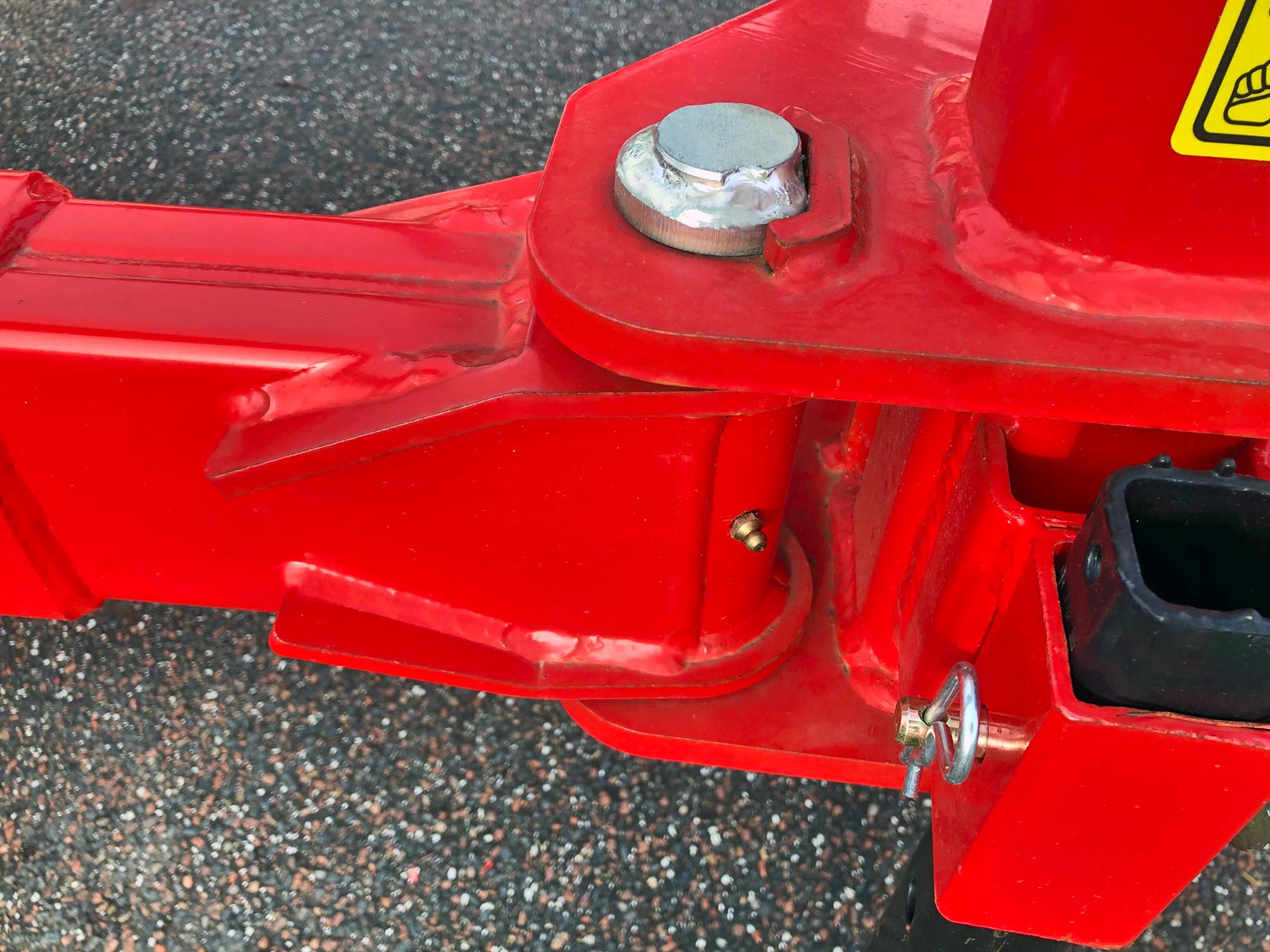

3-point suspension

The frame of the 3-point suspension is rolled into a hollow profile, which provides a very high strength to withstand the high loads during work with the machine.

Working area

Working area chart for FKR-150.

Working area 2

Working area chart for FKR-150.

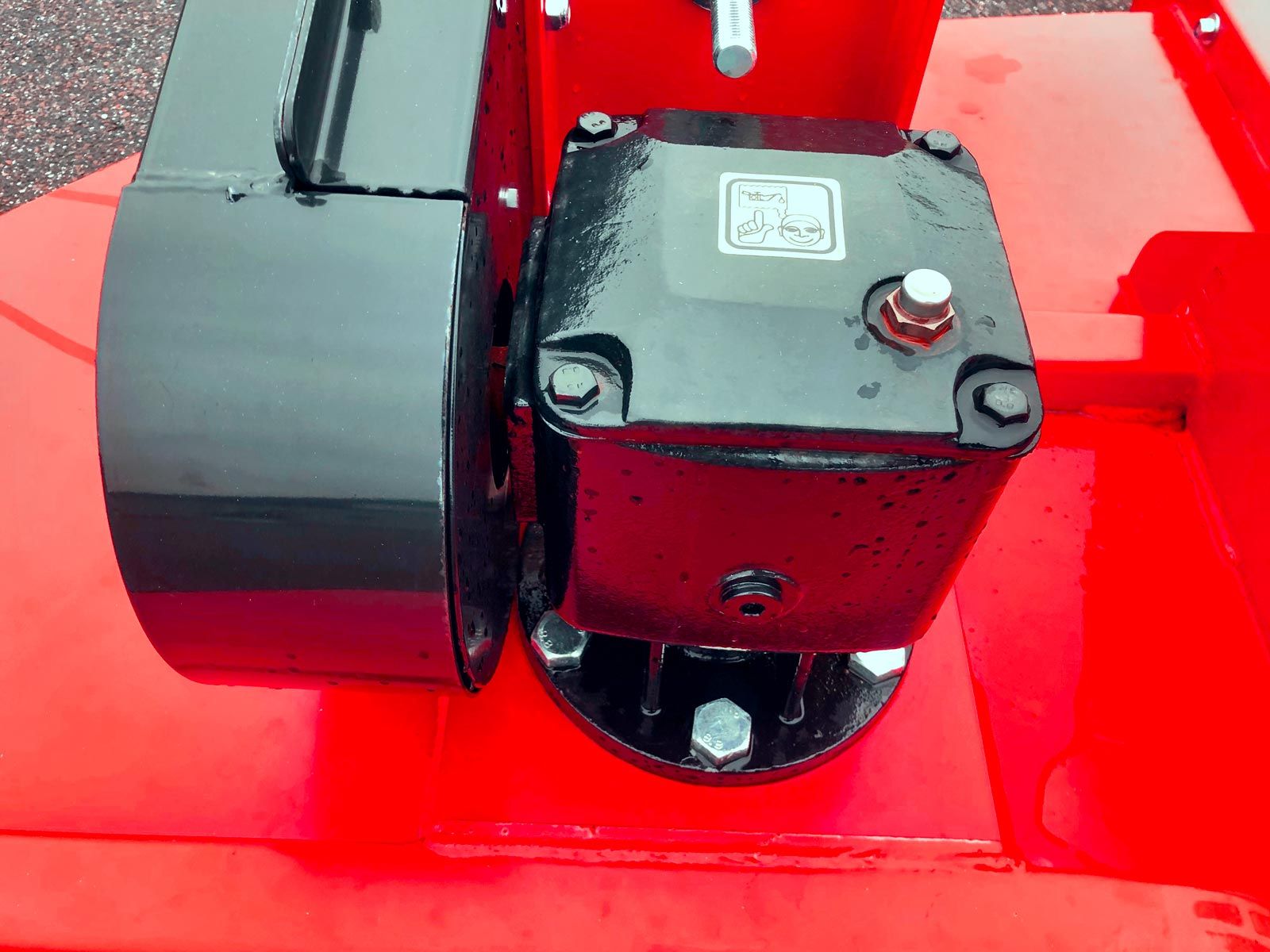

Gearbox, chain head

The chain head is mounted with a steel hub on the gearbox axle. The axle is well protected by the leg of the cast steel gearbox.

Gearbox

The gearbox is mounted on a reinforced mounting plate, which is fitted with a raised vent as standard.

Rubber cover

A durable 3-piece rubber cover mounted on the rear helps hold the material in place.

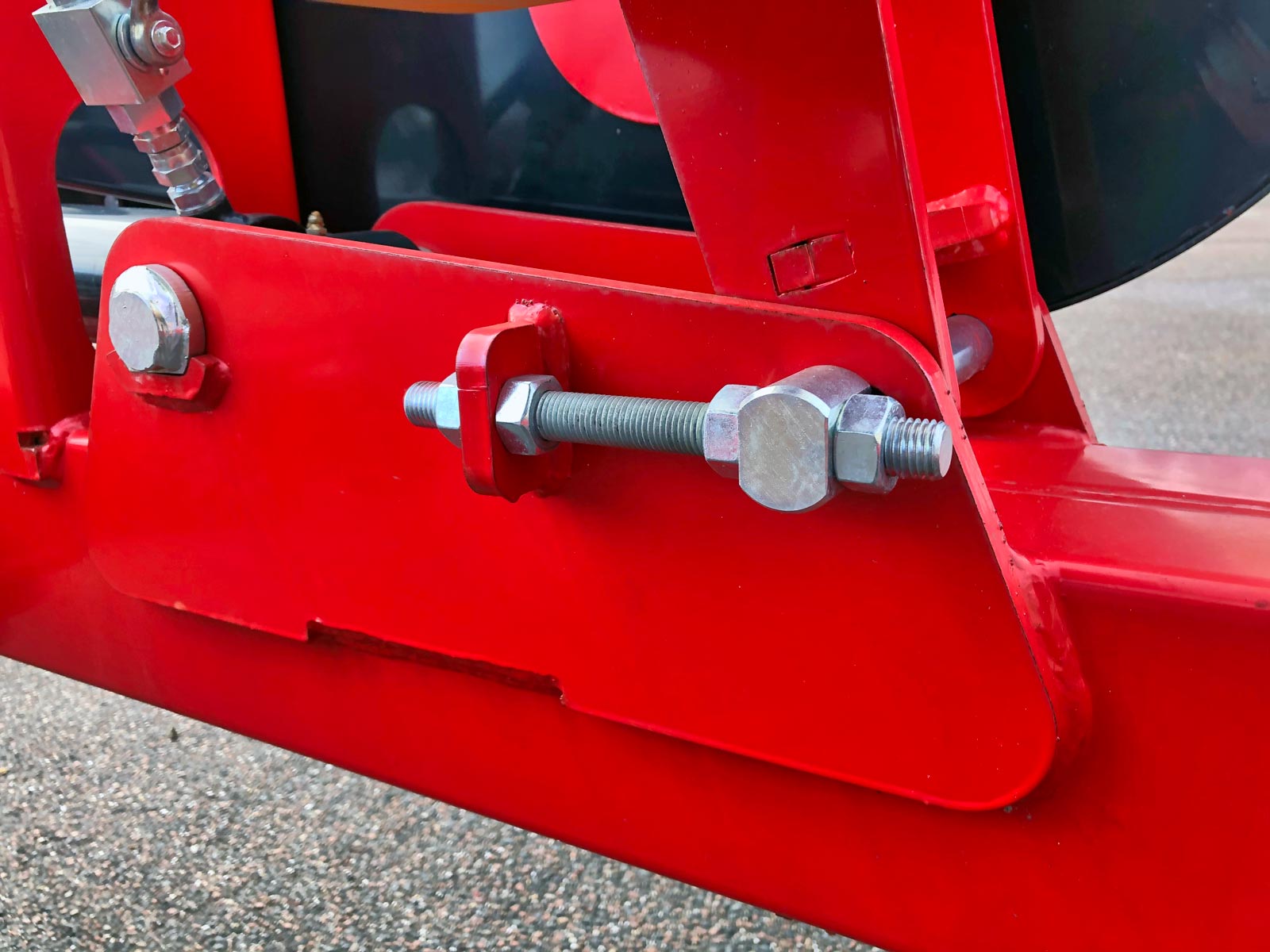

Adjustment bolt

The adjustment bolt for the large pulley ensures that you always have a 100% straight drive line on the powerbelt.

V-belt guard

Ventilated belt guard with a service hole to check if the belt is tightened.

Ball valve

The tilting cylinder is fitted with a locking valve with a handle, which is activated during transport and ensures that the machine does not swing out.

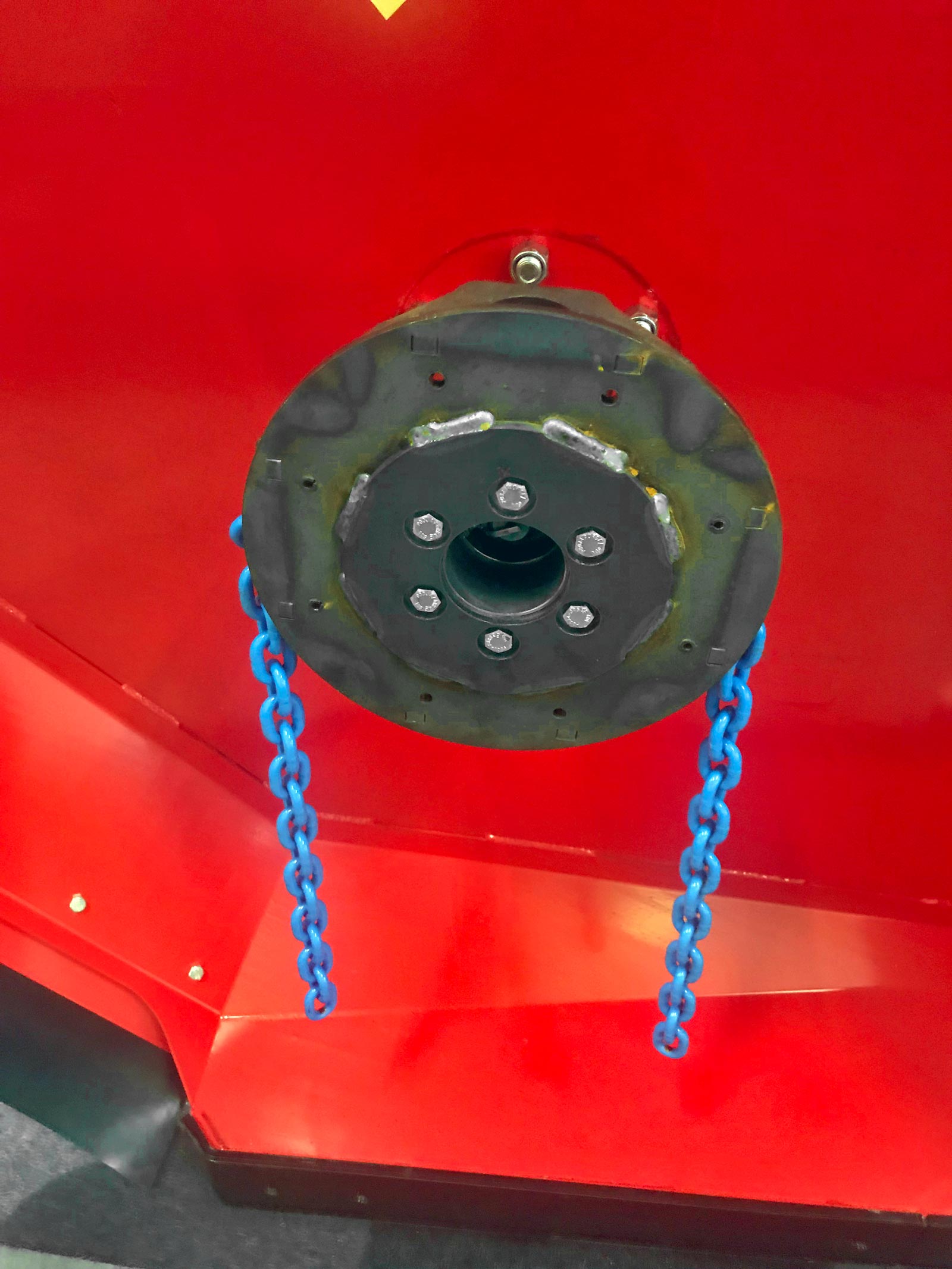

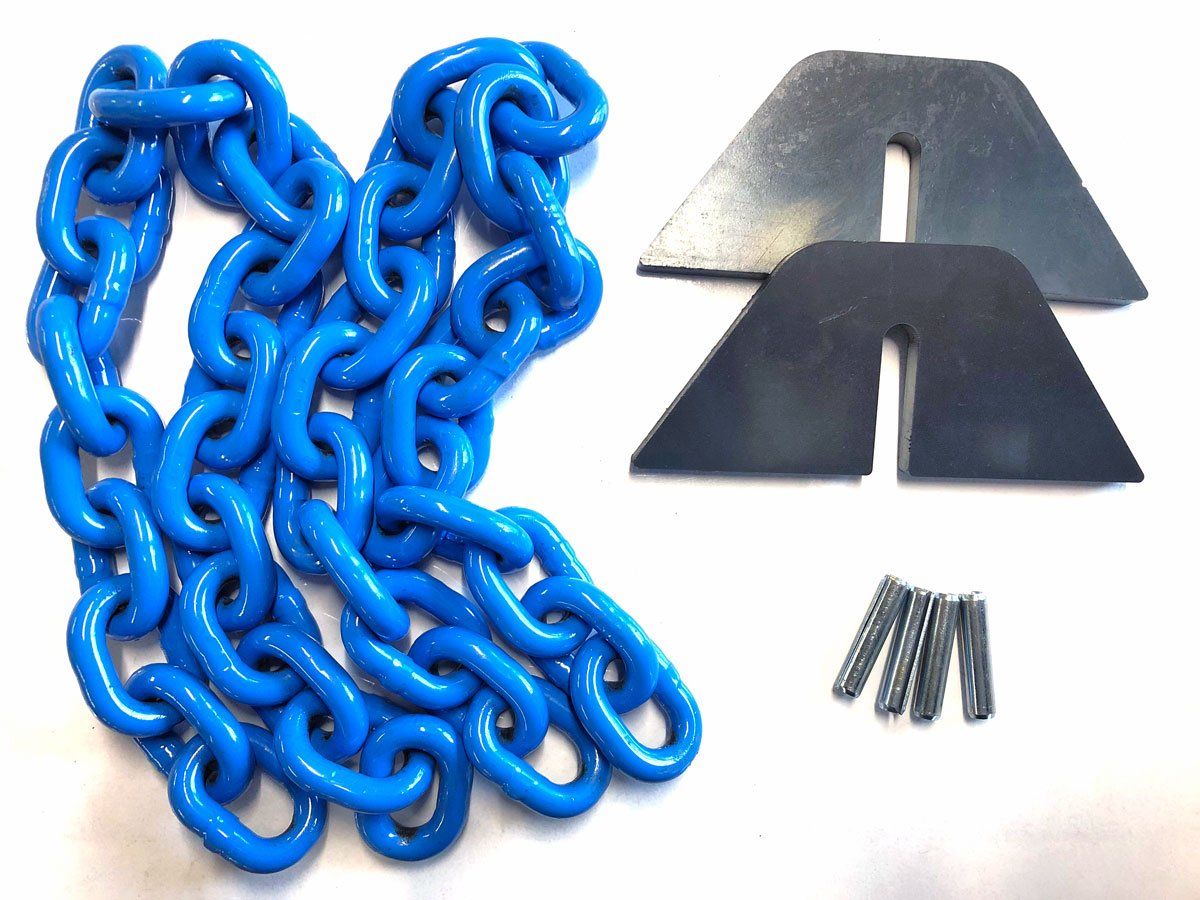

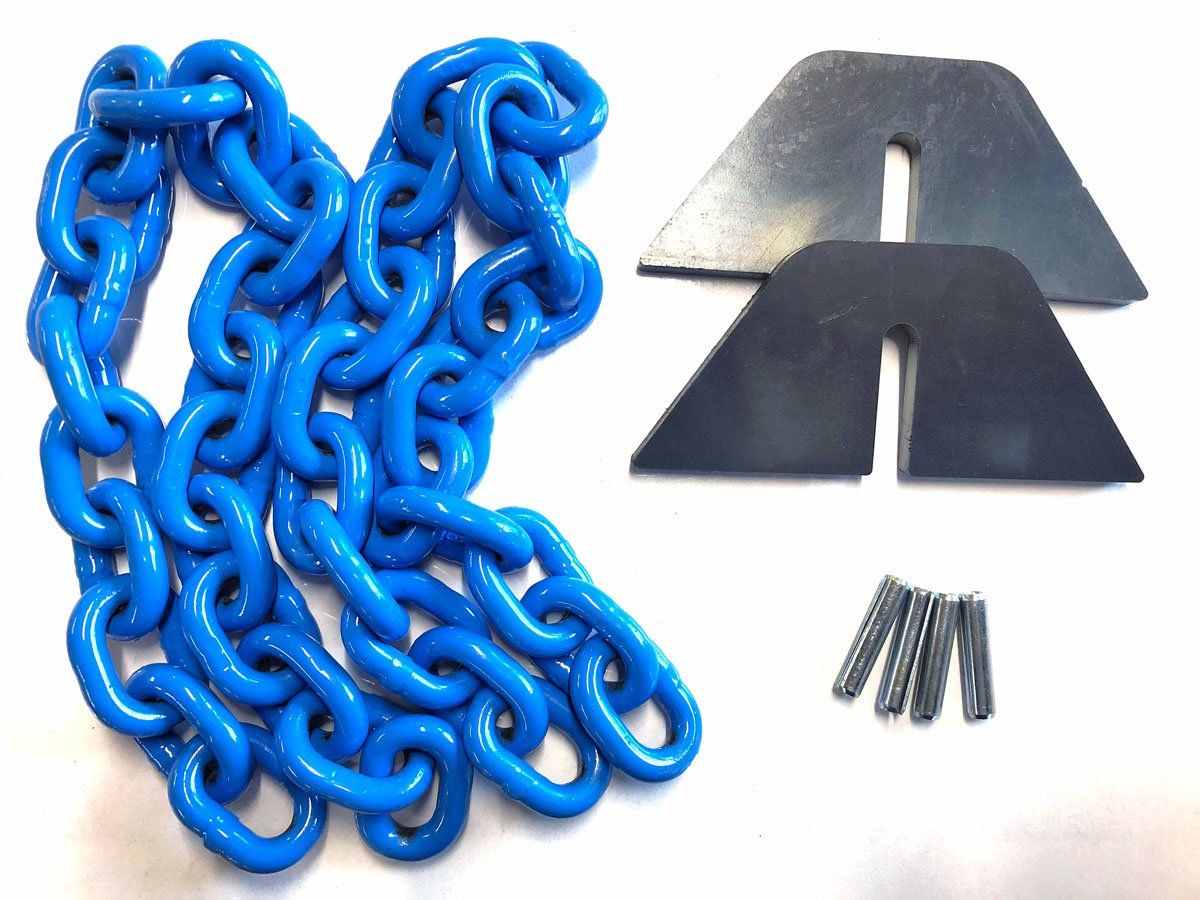

Chain head

All Fransgård chain mowers are fitted with 2 x 10 mm chains as standard. The chains are easily changed by knocking out the 2 pipe splitters.

Chain guard

The strong horns on each side of the front and the guard with reinforced edge guide the material into the machine. The guard has a chain fall as standard.

Locking valve

The offset adjustment cylinder has a locking valve, which ensures that the machine does not swing out during transport.

PTO hook

The 3-point suspension has a galvanised hook for the PTO axle when the machine is parked. The hook is easily turned away when the machine is working.

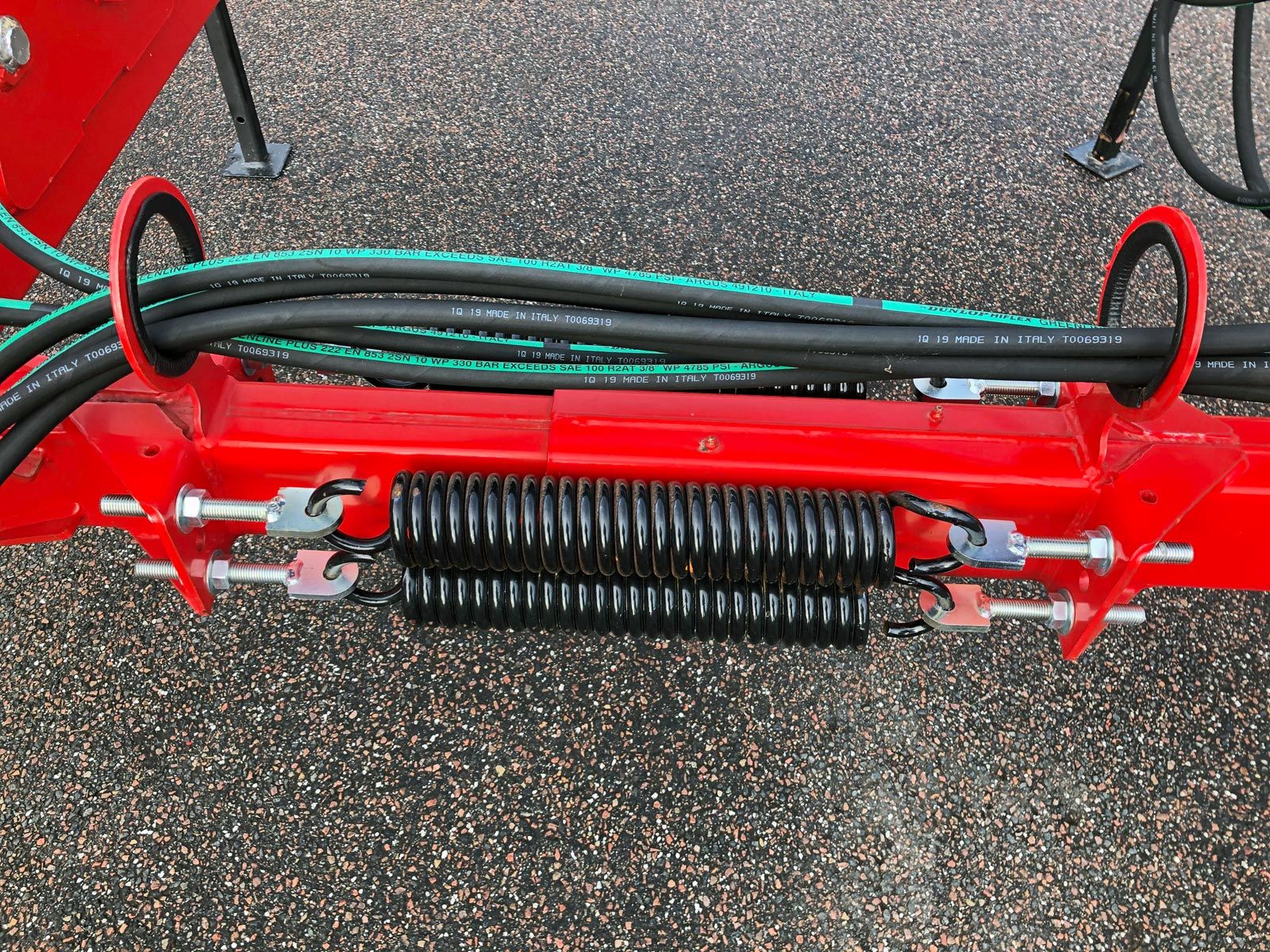

Collision protection

To relieve the machine from impact during work, the 3-point suspension has 3 compression spring that is released and pushes the machine back into place.

Belt tensioner 2

The external belt tensioner on the rear belt pushes a small wheel down the middle of the belt. There is also a guide wheel on this belt mounted in the middle.

Belt tensioner

The external belt tensioner makes it easy to tighten the belt.

Assembly bolts

All assembly bolts mounted on the FKR-1501 are galvanised.

Safety label

The chain mower is clearly marked with large yellow safety warnings.

Hose holder

Holder for hydraulic hoses is standard.

Slide rails

The Hardox-500 slide rails are designed to slide easily over tree stumps, etc.

Swivel joint

The greasable swivel is mounted on a heavy duty axle and 4 half bushes, which are made of special steel and mounted with greasable bolts.

Greasable joints

All rotating joints have the option of grease lubrication.

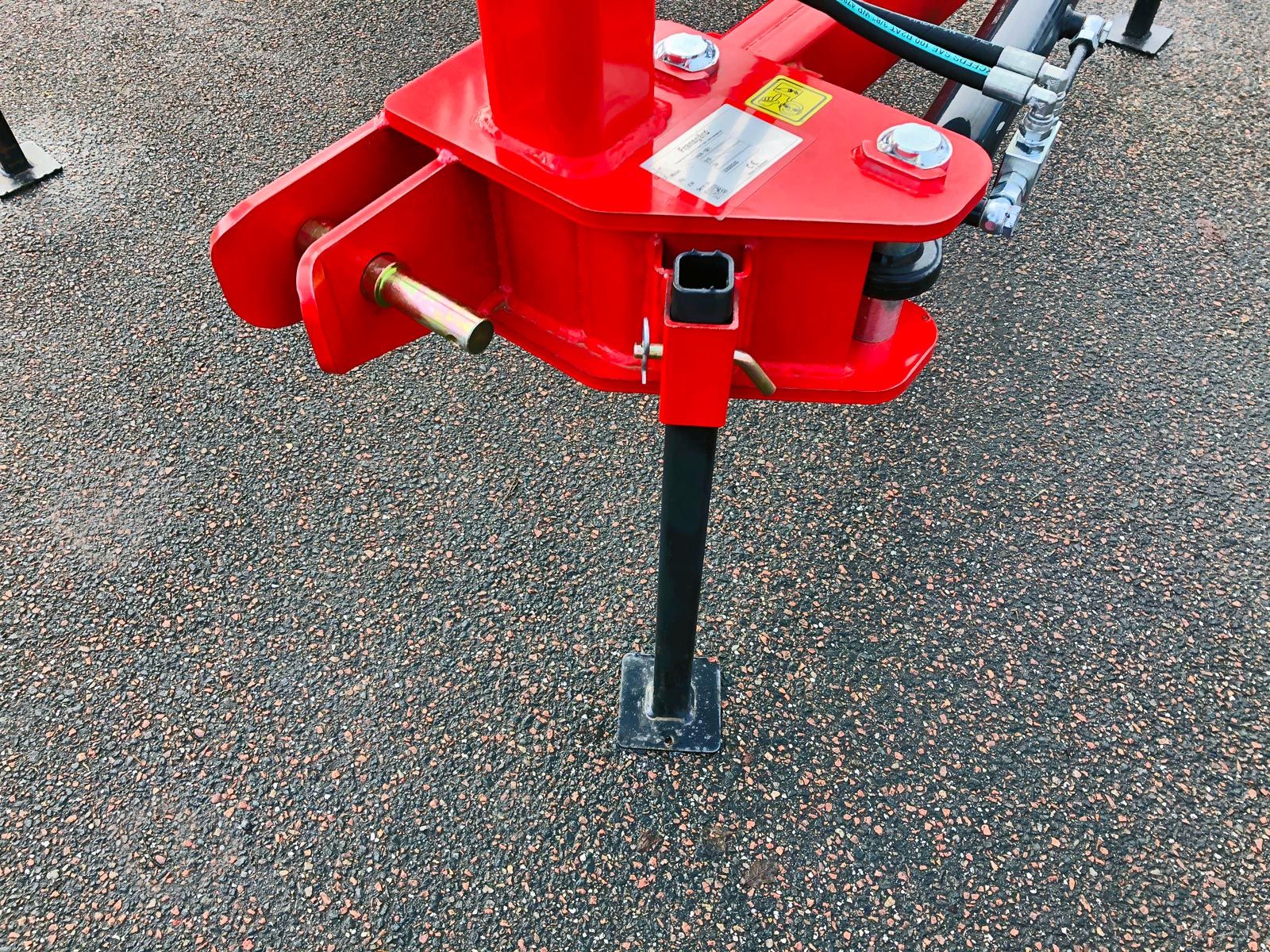

Support legs

The 4 support legs ensure stable parking of the machine and they are easily lifted up during work, so they are always accessible on the machine.

Tilt cylinder

The powerful cylinder ensures optimal operation from horizontal to vertical.

Top bar attachment

The top bar attachment on the FKR has both a fixed and an elongated hole. By using the elongated hole, the machine follows a hilly terrain better.

Optional extras:

Item No. 6130

Hydraulic cylinder to lift the chain fall, allowing large amounts of material to enter the machine more easily. Supplied complete with hoses and pipework.

Item No. 6134

Chain kit 10 mm with bracket and splitter

Item No. 6136

Chain kit 13 mm chain bracket and splitter.

Download PDF files

See our information material here, where you can also read it online, print or download the file.