Leveller GT-250HNZ · GT-275HNZ

Presentation

Fransgård's hydraulic GT-250HNZ and GT-275HNZ levellers are used for efficient levelling of soil, clearing of snow and smoothing roads especially in very hilly landscapes and where often only smaller tractors (max. 120 hp.) can be used.

The construction is lighter than our DKH models, but it comes with many of the same features.

Many settings and options

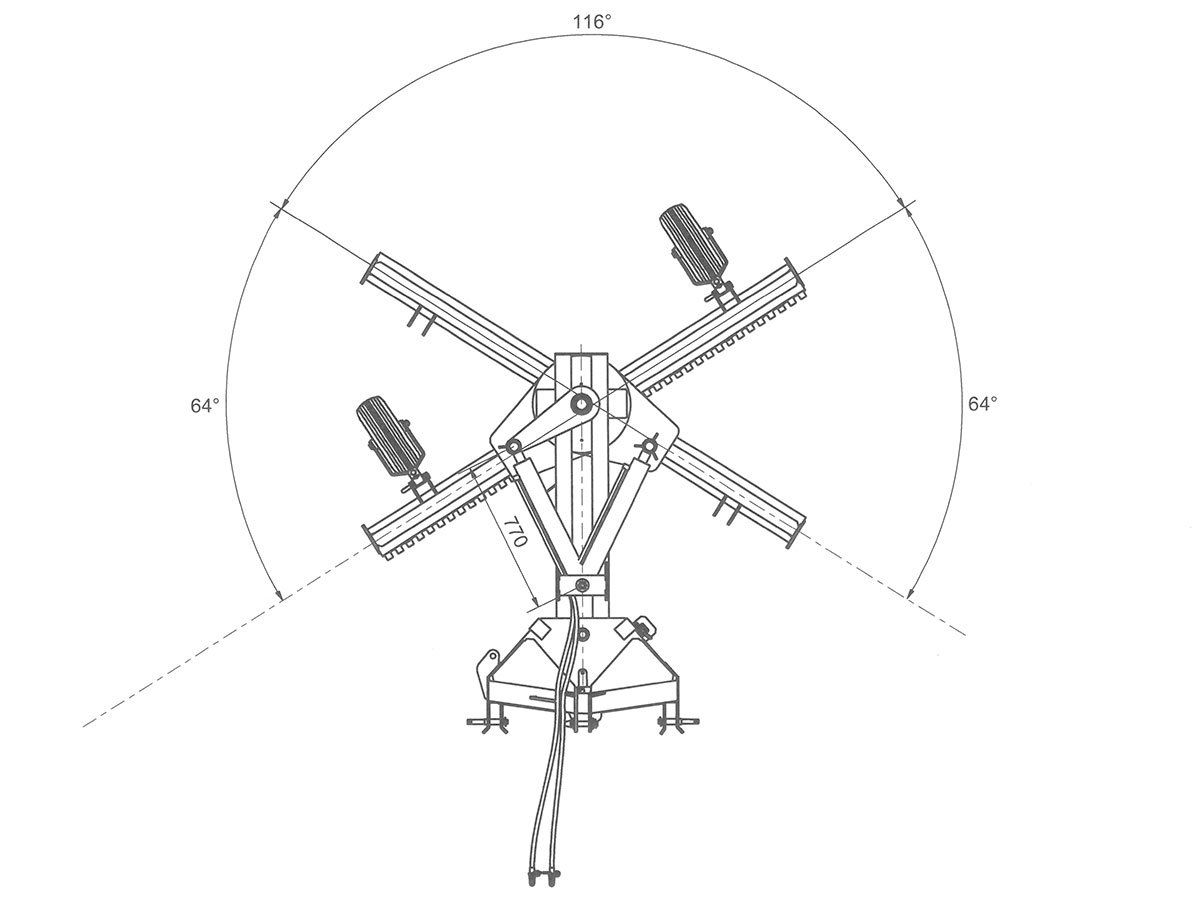

The machine is manufactured with a high basic weight, partly via the heavily manufactured blade with a 75 mm connecting axle. The blade is hydraulically rotatable up to 244° as standard and can be mechanically tilted 55 cm either to the right or left.

The three-point suspension is standard mechanical with the possibility to adjust the horizontal cutting angle by +/- 20°. A hydraulic suspension can be purchased, further increasing flexibility. Interchangeable levelling plates are fitted as standard.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Technical data:

| Model: | GT-250HNZ | GT-275HNZ |

|---|---|---|

| Working width | 250 cm | 275 cm |

| Blade height | 60 cm | 60 cm |

| Mechanical offset adjustment, right/left or hydraulic (Optional) | 55 cm | 55 cm |

| Hydraulic rotating blade | 244° | 244° |

| Hydraulic connectors | 1 double | 1 double |

| Reversible wear steel Hardox 500 | Std. | Std. |

| Push/front mounting | Yes | Yes |

| Support wheels | Possible | Possible |

| Snow blade right | Possible | Possible |

| Side flap | Possible | Possible |

| 3-point suspension | Cat II | Cat II |

| Weight | 545 kg | 575 kg |

| Tractor Performance | Max. 120 hp | Max. 120 hp |

Details:

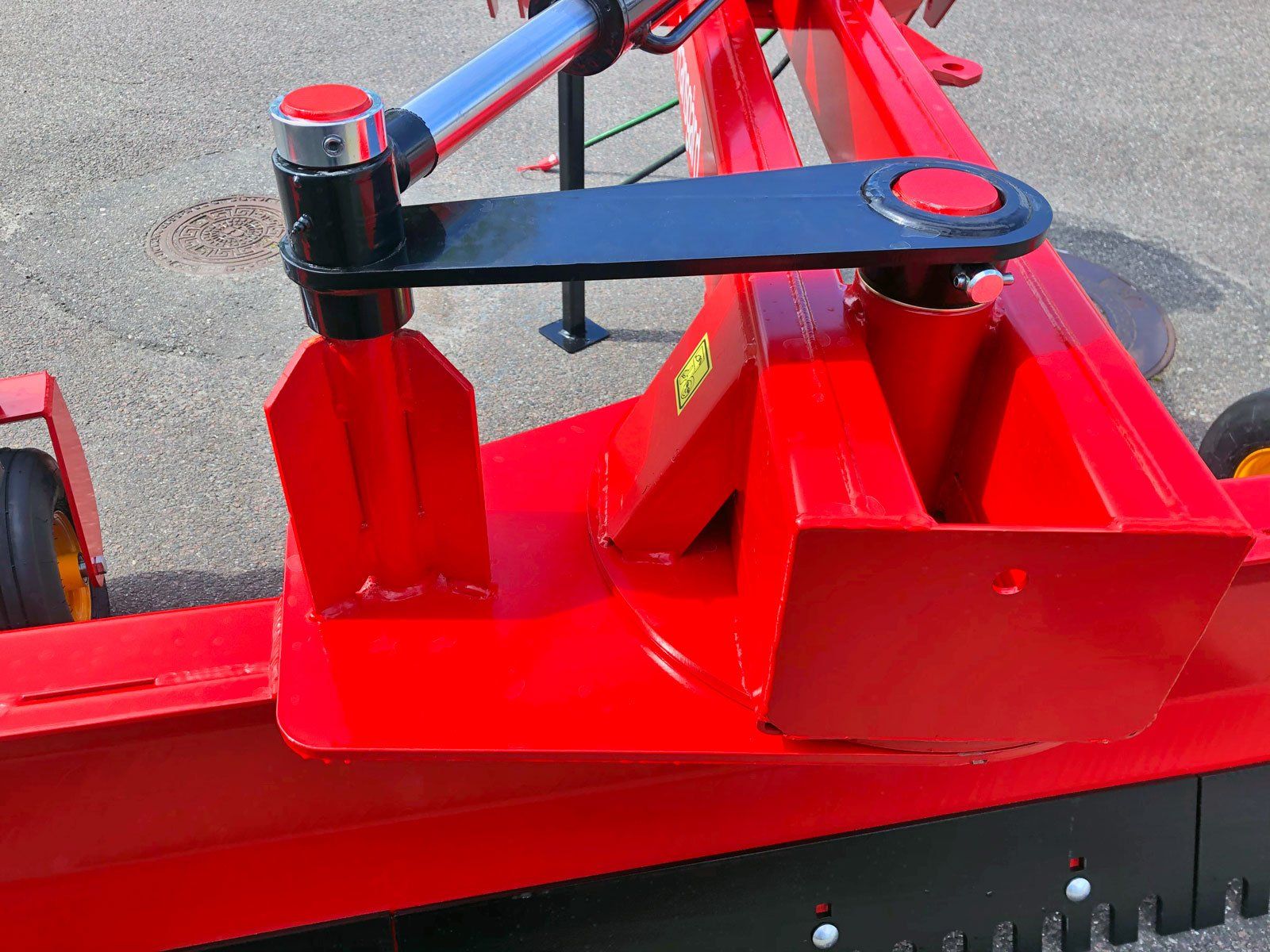

Custom-designed hinged eye

Prevents backlash during use.

Top bar attachment

The top bar attachment has both a fixed hole and an elongated slot, where the top bar bolt can usefully be mounted for, e.g., when levelling roads. This way, the leveller will better follow the terrain and a better end result is achieved.

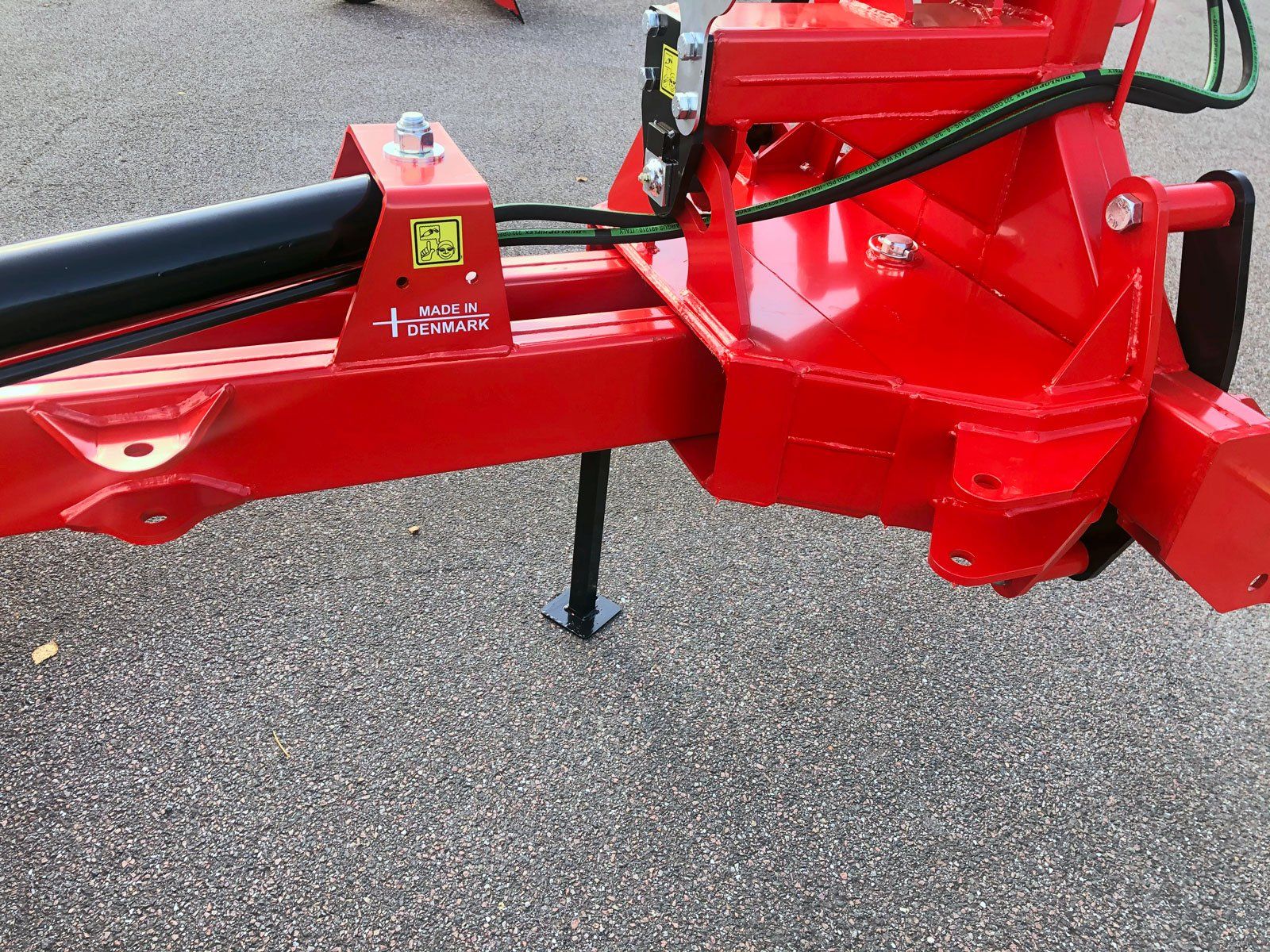

Manual horizontal setting

The horizontal cutting angle can be set in 5 positions as standard; up to 17 degrees to each side, without the need for tools. A hydraulic cylinder (item no. 2515) can be fitted as an optional extra.

Support legs up

The support leg is easily lifted and secured in the holder during work, so you always have the support leg with you when you need to park the leveller again.

Hydraulic hose holder

The leveller is fitted with a holder for the hydraulic hoses as standard.

Main bolt 3-point

The 3-point suspension rotates around the strong 75 mm special steel main axle.

Degreemeter

The leveller is fitted with a degreemeter, which is clearly visible from inside the tractor.

Main axle

The blade and boom are assembled with a strong 75 mm main bolt

Prepared for wheels

The leveller is prepared for the installation of wheel sets item no. 2512 or 2513.

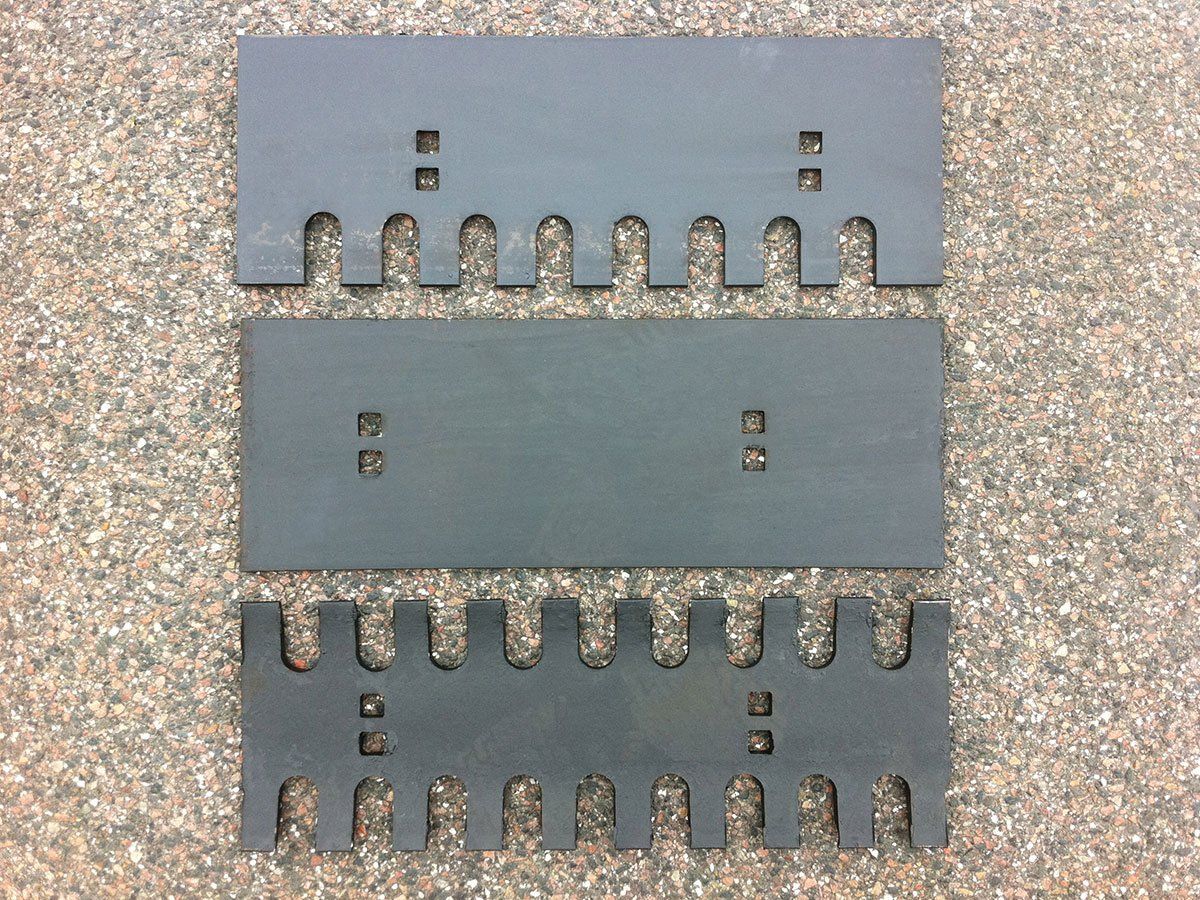

Blades

Reinforced ends on the blade of the leveller, which are also prepared for mounting the side flap and snow blade.

Reversible wear steel bolts on with 16mm steel bolts grade 12.9.

Pivot

The large pivot on the blade can be greased via lubrication nipples in the pivot plate on the boom.

Cylinder attachment

Heavy duty cylinder hinge in special steel provides stable operation and long life.

Bolt for manual offset adjustment

The leveller can be mechanically offset adjusted 55 cm to the right or left side.

The locking bolt is mounted with a tractor split. All locking bolts are galvanised.

Fitting for hydraulic offset adjustment

All GT-HNZ levellers are prepared for the installation of hydraulic offset adjustment (item no. 2528).

Blade rear

Strong blade with reinforcements at the rear. The lower reinforcement at the rear is designed so that you can reverse with the leveller without turning the blade, and any excess material, for example, when you come to an asphalt road, you will be able to reverse over and the leveller will press and distribute the material out into the road.

3-point rear

The 3-point suspension has a guide bolt at the rear with a hardened bush that can be greased.

3-point cat II

With the 3-point suspension on Fransgård's leveller, the lift arms can be mounted at 2 different heights to fit most tractors.

Blade cylinder

A strong blade cylinder with 45 mm stick ensures that the blade is kept stable.

The cylinder is well protected on top of the boom.

Turning radius

The GT-HY leveller can be hydraulically turned up to 244 degrees.

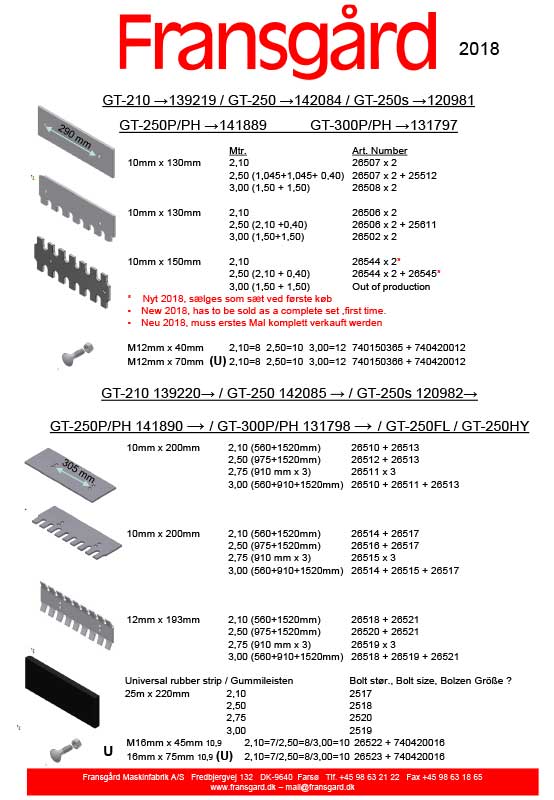

Wearing steel all

The leveller is fitted as standard with reversible smooth/toothed wear steel. You can have your leveller supplied with smooth or toothed wear steel at no extra cost if this is stated when ordering the leveller. The leveller can also be fitted later with one of the other types of wear steel.

Optional extras:

Item No. 2511

Towing shoes help prevent the cutting edge from going too deep during work. Made of Hardox 500 steel

Item No. 2512

Wheel set with wheel width 15 x 600, adjustable up and down via 2 bolts with a ring split.

Item No. 2513

Wheel set with wheel width 15 x 600, stepless height adjustment via spindle. The wheels can turn 360 degrees, so you can reverse with the leveller without turning the blade. The wide rear wheel spacing makes for a smoother operation.

Item No. 2517-2520

Rubber blade for mounting on all Fransgård models of levellers. The rubber blade is mounted behind the existing wear steel, which acts as a backstop on the rubber blade. It should be fitted 2-3 cm lower than the wear steel and can be continuously moved downwards as it wears down.

You drill the holes in the rubber blade yourself and mount it with the bolts provided.

Item No. 2528

Hydraulic offset adjustment can shift the blade up to 55 cm to the right or left side, so you don't have to drive with the tractor wheel in the ditch, for example. The hydraulic cylinder allows the blade to have offset adjustment exactly to the required distance if space is at a premium.

Item No. 2533

Side flap to hold the material. Can be mounted on both the right and left side.

Item No. 2533

All Fransgård's newer levellers are ready for mounting side flaps and are easily mounted with the 3 bolts provided.

Item No. 2545

Snow blade for the right side, cut the snow edge diagonally so that it does not collapse and in behind the tractor where you have just driven.

Item No. 2545

All Fransgård's newer levellers are ready for mounting snow blades and are easily mounted with the 3 bolts provided.

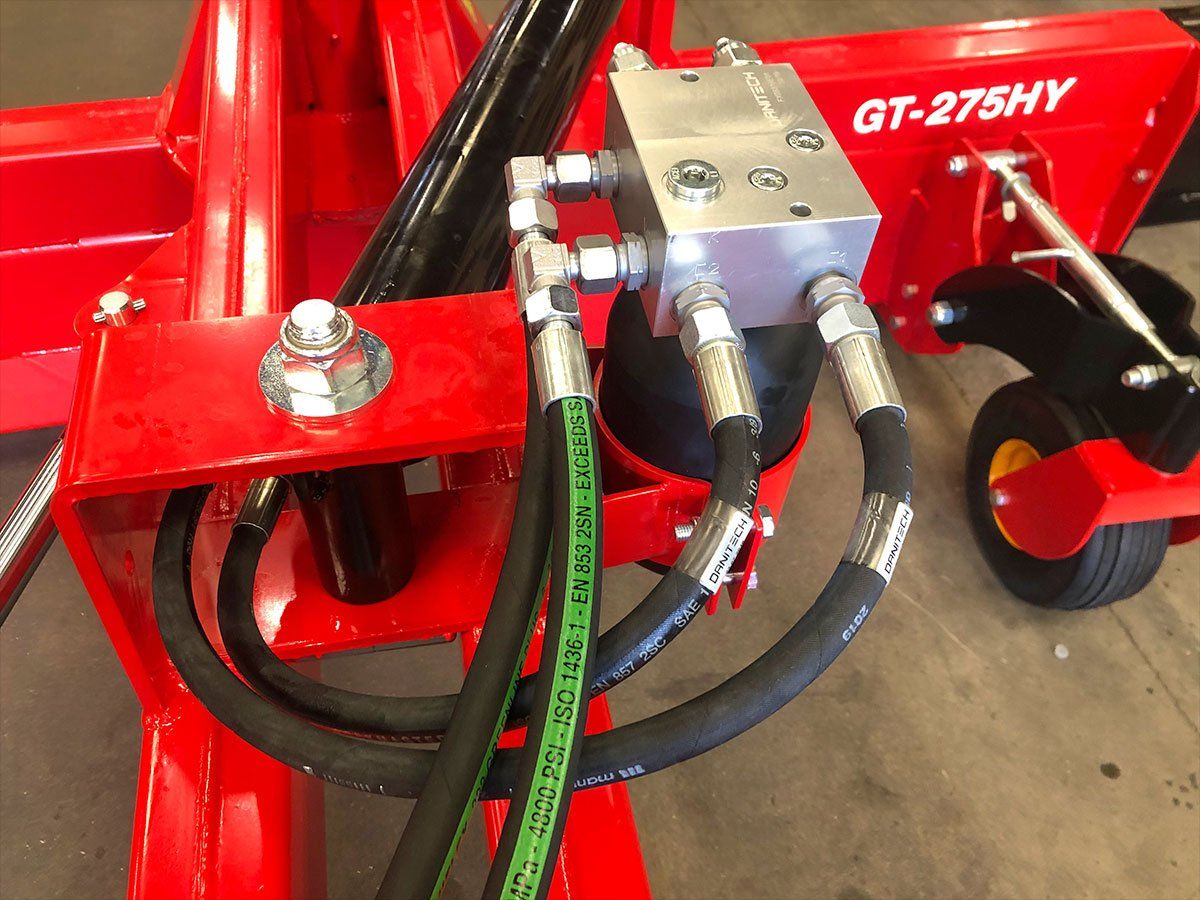

Item No. 2543

Shock valve with an accumulator for mounting on the blade cylinder of all Fransgård hydraulic levellers.

Item No. 2543

The shock valve will relieve the cylinder and the leveller when hitting objects and minor impacts, in both the right and left side of the blade. Supplied as a complete set with assembly instructions.

Item No. 2544

Shock valve for mounting on the blade cylinder of all Fransgård hydraulic levellers.

The shock valve will relieve the cylinder and the leveller when hitting objects and minor impacts, in both the right and left side of the blade. Supplied as a complete set with assembly instructions.

Download PDF files

See our information material here, where you can also read it online, print or download the file.