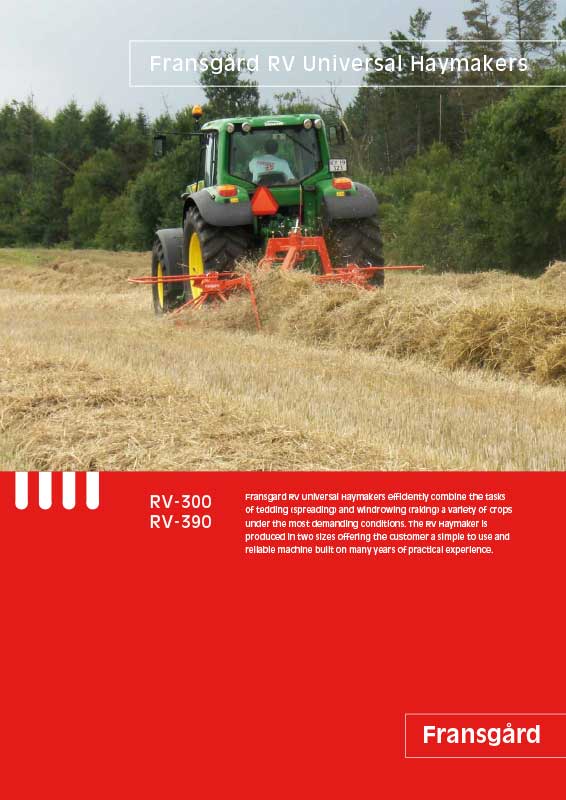

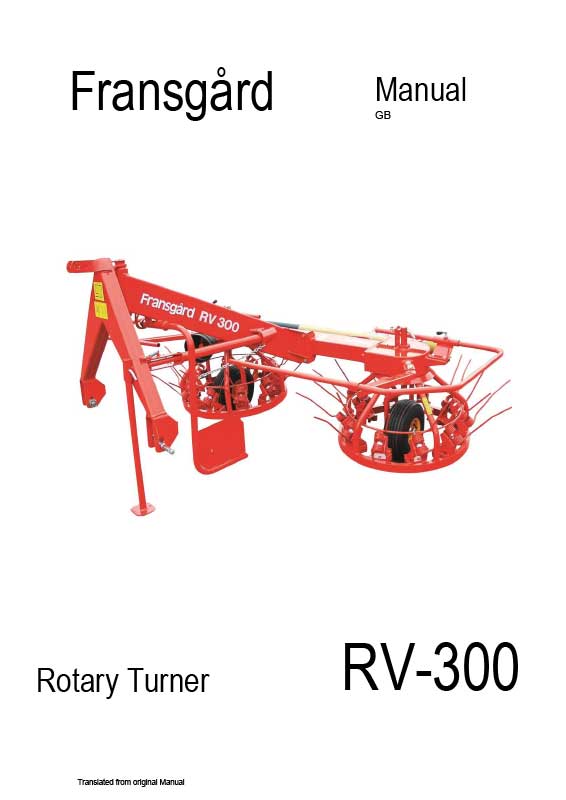

Combi rake RV-300/RV-390

Presentation

The simple and very robust construction has made the Combi Rake RV attractive all over the world and the model is by far the most powerful on the market. Fransgård has been manufacturing this type of rake for more than 30 years, which has contributed to extensive know-how in this type of machines.

The rake is used for many purposes such as spreading grass and hay, aerating a straw swath and raking up the materials. When aerating, the swath is moved 60-70 cm to the side, leaving it at the same time in a high airy even swath.

Efficient rake for spreading, aerating and collecting

The RV rake is available in 2 sizes with a working width of 3.0 m or 3.9 m and with 2 or 4 wheels as standard. The rake is fitted with a gimbal between the rotors to avoid stoppages.

The rake is built in a robust construction with specially hardened crown/gear-pinions above each rotor and strong U-iron at the bottom, where the spring-loaded rake springs are mounted. The disc springs are moved from the raking to the spreading position without using tools.

The centrifugal force pushes the springs down into the working position. If they hit a stone or a hole in the field, they are raised up instead of going into the ground. During transport, the rake is manually turned behind the tractor.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Technical data:

| Model: | RV-300 | RV-390 |

|---|---|---|

| Working width | 300 cm | 390 cm |

| Transport width | 250 cm | 320 cm |

| Rotor number | 2 | 2 |

| Rotor diameter | 144 cm | 180 cm |

| Number of rake springs per rotor | 10 | 14 |

| Number of wheels | 2 | 4 |

| Wheel size | 15x6.00-6/4 ply | 15x6.00-6/4 ply |

| Hydraulic connectors | - | - |

| 3-point suspension | Cat II | Cat II |

| PTO connector rpm | 400/540 | 400/540 |

| Power requirement kW/HP | 22 / 30 | 30 / 40 |

| Working speed km/h | 8-15 | 8-20 |

| Weight | 357 kg | 489 kg |

Details

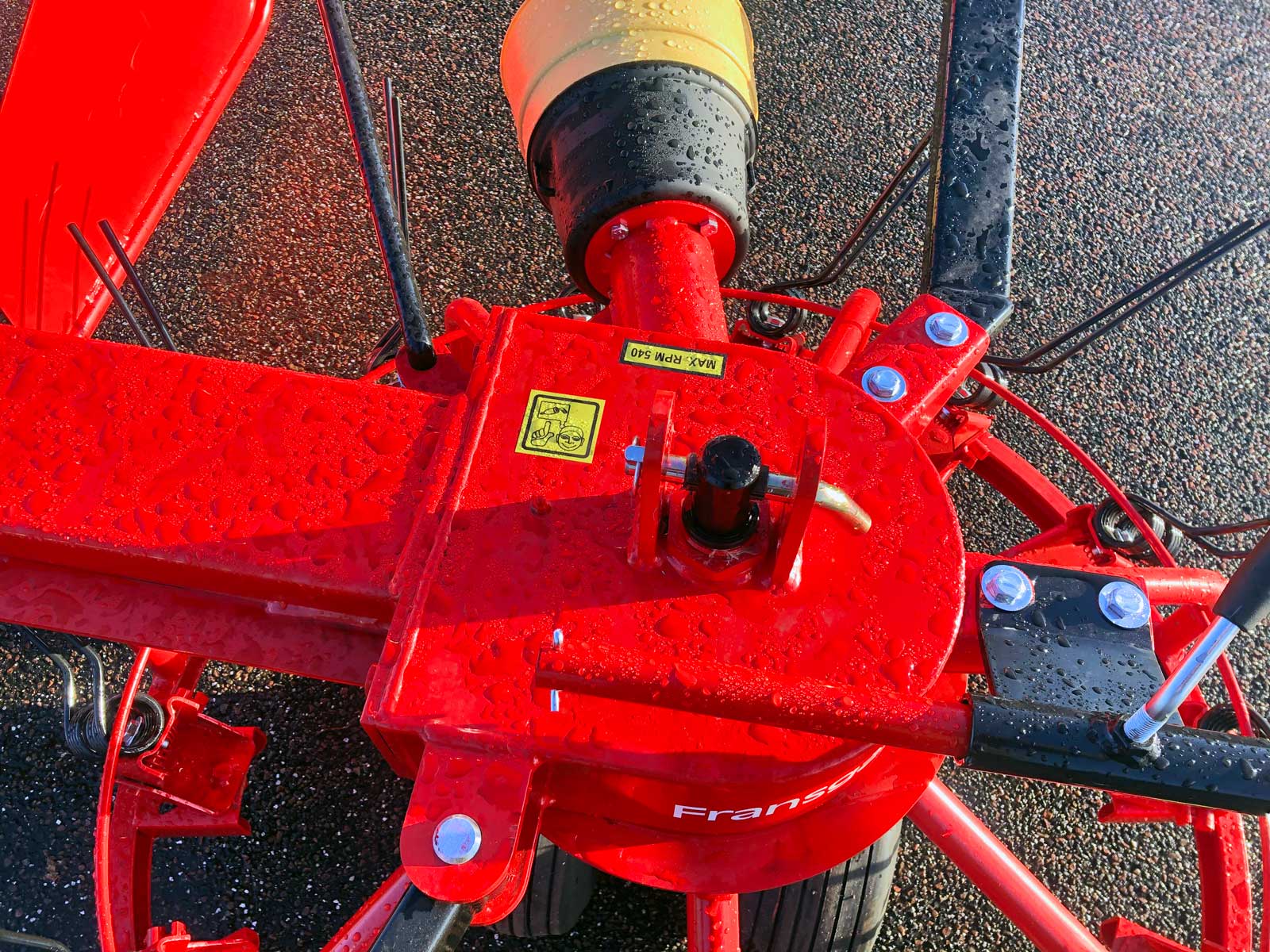

Gear house

The durable crown wheel and gear-pinion are well protected in the gear housing above each rotor and lubricated via the lubricating nipple mounted on top of the housing.

Main frame

In the main frame between the rotors is the strong connecting axle, which ensures stable operation and high efficiency (no slipping v-belt). The cutters are adjusted to the desired width and position of the cut by inserting the bars into the holes without using tools.

Setting the rake springs

A clear yellow mark on each rotor indicates the setting of the rake spring for whether raking or spreading is desired.

Adjusting the wheels

The height adjustment on the wheels has 3 positions that are adjusted by moving the bolt without using tools. During winter storage, you can remove the bolt and leave the machine directly on the rotors, so you do not stress the wheels.

Lift bracket

The RV-390 comes standard with movable lift arm bracket to help the machine follow the terrain while working.

Lock

The transport lock on the RV-390 can be deactivated from the cabin via the green cord.

Labels

Clear yellow instruction labels are mounted all around the machine for quick and easy operation.

Positions

The RV-390 can work in a fixed position, which can be an advantage in terrain with a large height difference, or in a floating position, where the 3-point suspension rotates with it and the powerful shock absorber keeps the machine stable.

Rake springs, working position

The rake springs automatically settle into the working position when the rotors start to rotate

Rake spring changeover

When switching from raking to spreading, the rake spring is lifted slightly and turned over into the second hole on the rake spring suspension.

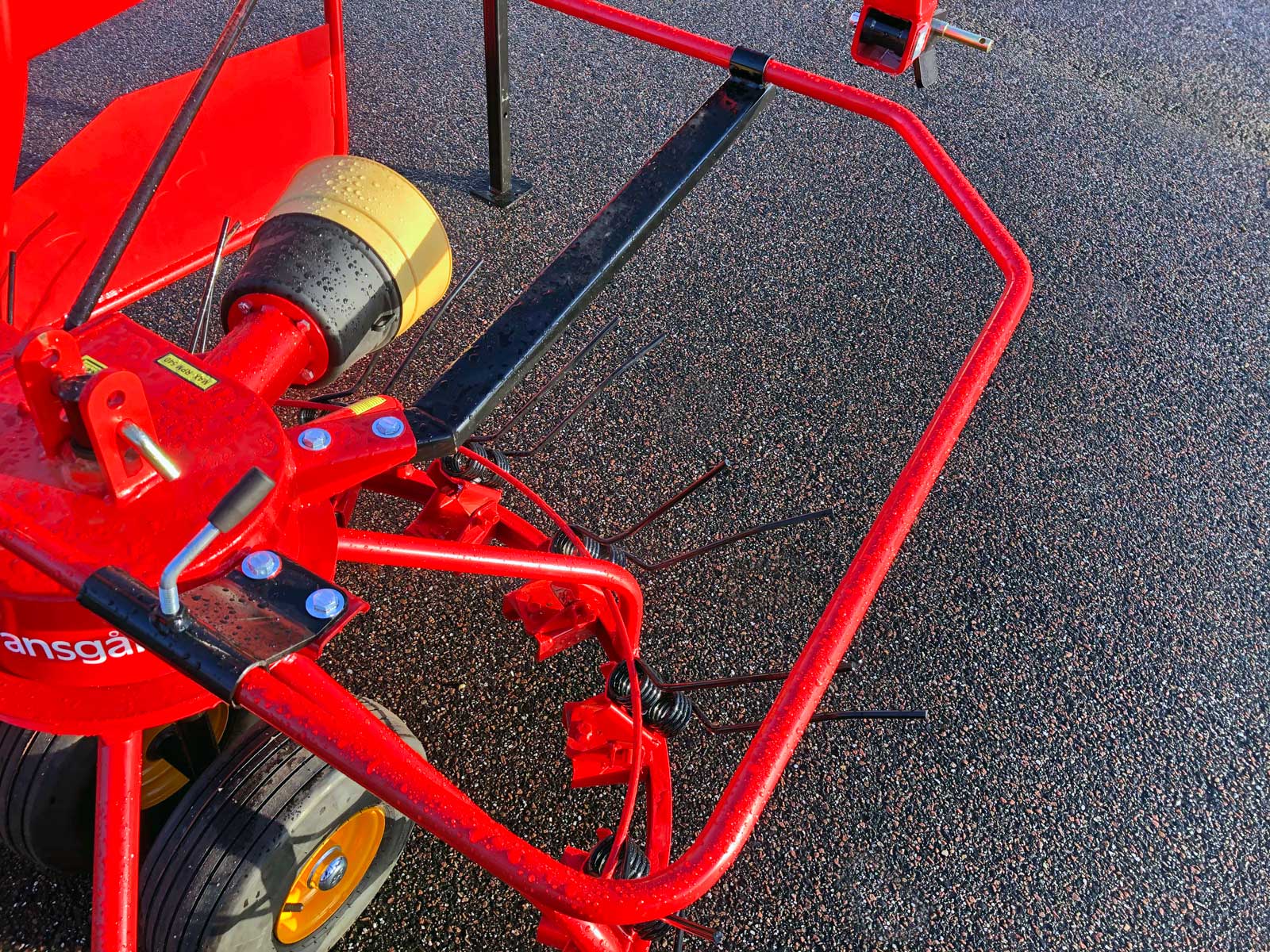

Rake spring suspension

The complex bracket for the rake springs has a spring mounted under the rotor, which holds the bracket in the desired position. The spring, which is mounted on the axle over which it tilts, ensures that the rake spring tilts up if it hits an object or the ground while working. This extends the life of the rake spring.

Rake spring up

During transport and storage, the rake spring is always folded up.

Rake springs

The rake springs consist of both right and left sides, while there are 2 different rake springs on each rotor: one v-shaped and one parallel, alternately placed all around. This helps to ensure the best possible raking and spreading.

Safety bar

The safety bars on each rotor are easily adjusted to the desired position via a single lever.

Swath separator

The spring-mounted swath separator guard ensures that the machine does not throw shorter material from one rotor to another during work. The guard can be removed for aeration or moving a swath.

Shock absorber

The telescopic shock absorber is fitted as standard and keeps the machine in the right place during work.

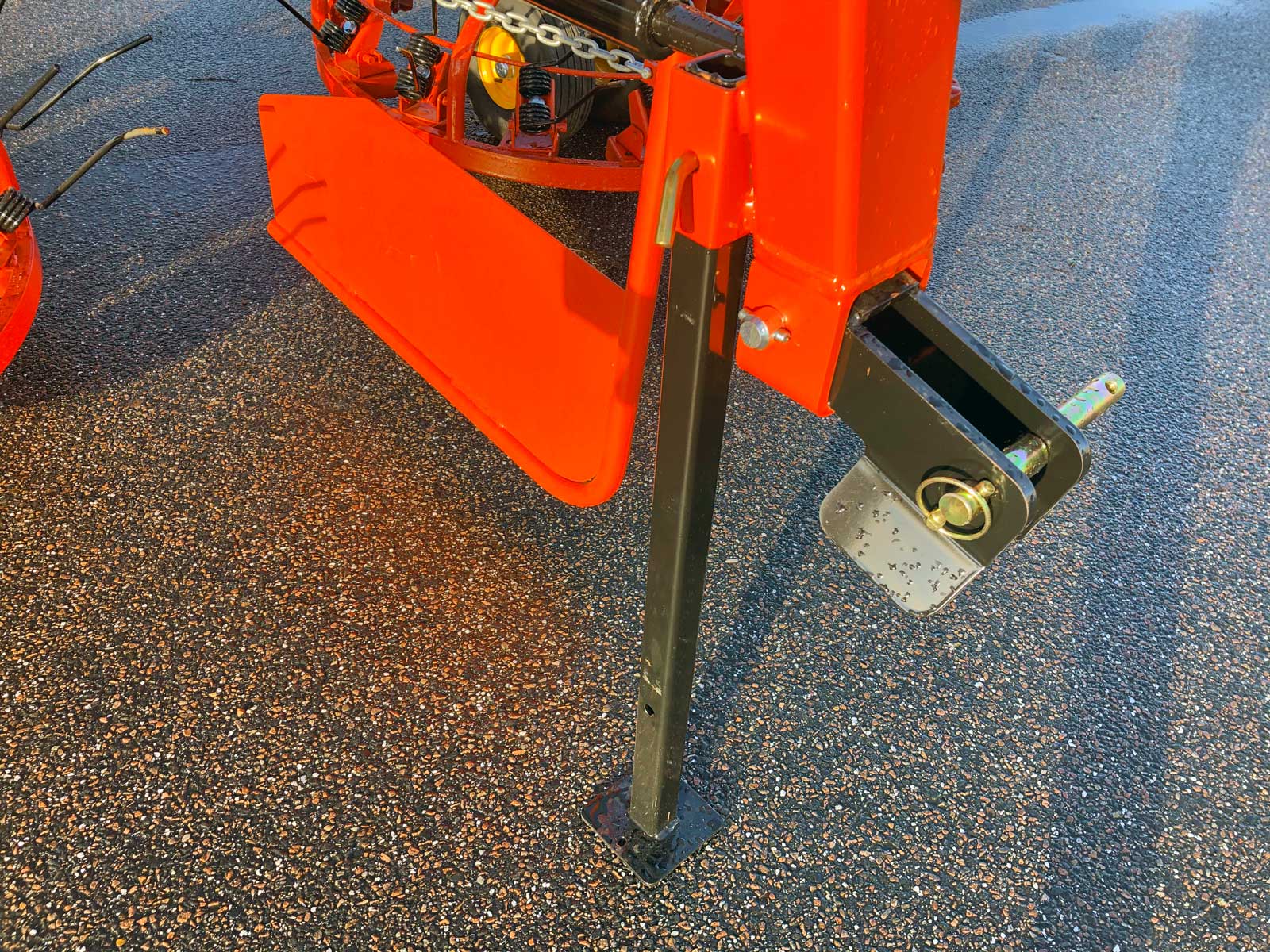

Support leg

The support leg is pushed up into the holder while working with the machine.

Wheels

The RV-300 has a fixed wheel under each rotor as standard. Twin wheels can be purchased as extra equipment.

Swath collector

The 2 swath collector arms are easily mounted in the bracket on the gearbox and completely removed when spreading the material

Transport lock off

The transport lock is manually deactivated before work if you want the 3-point suspension to rotate with you.

Transport lock on

The transport lock is activated manually before transport or if a fixed working position is required.

RV-390 wheels

The RV-390 has twin wheels under each rotor as standard.

Download PDF files

See our information material here, where you can also read it online, print or download the file.