Combi Rake TI-5000

Presentation

Fransgård's mechanical Combi Rake TI-5000 model is easy to service and has low operating costs. The rake function is efficient and the machine has a strongly built construction. The 3 working positions amply cover the need for an efficient combi rake.

By raking to the centre, the width of the swath can be precisely adjusted to the pickup that will collect the crops. The larger the working width, the larger the swath width. Furthermore, it can be set to rake to the side, thereby collecting 2 swaths in the same operation. When you want to have full control over the raking process, this is the perfect machine.

The model has a spreading function that can be used if spreading is not the most important thing. The spreading function is not quite on a par with a specifically developed spreading/turning rake.

Efficient rake combined with the option for spreading

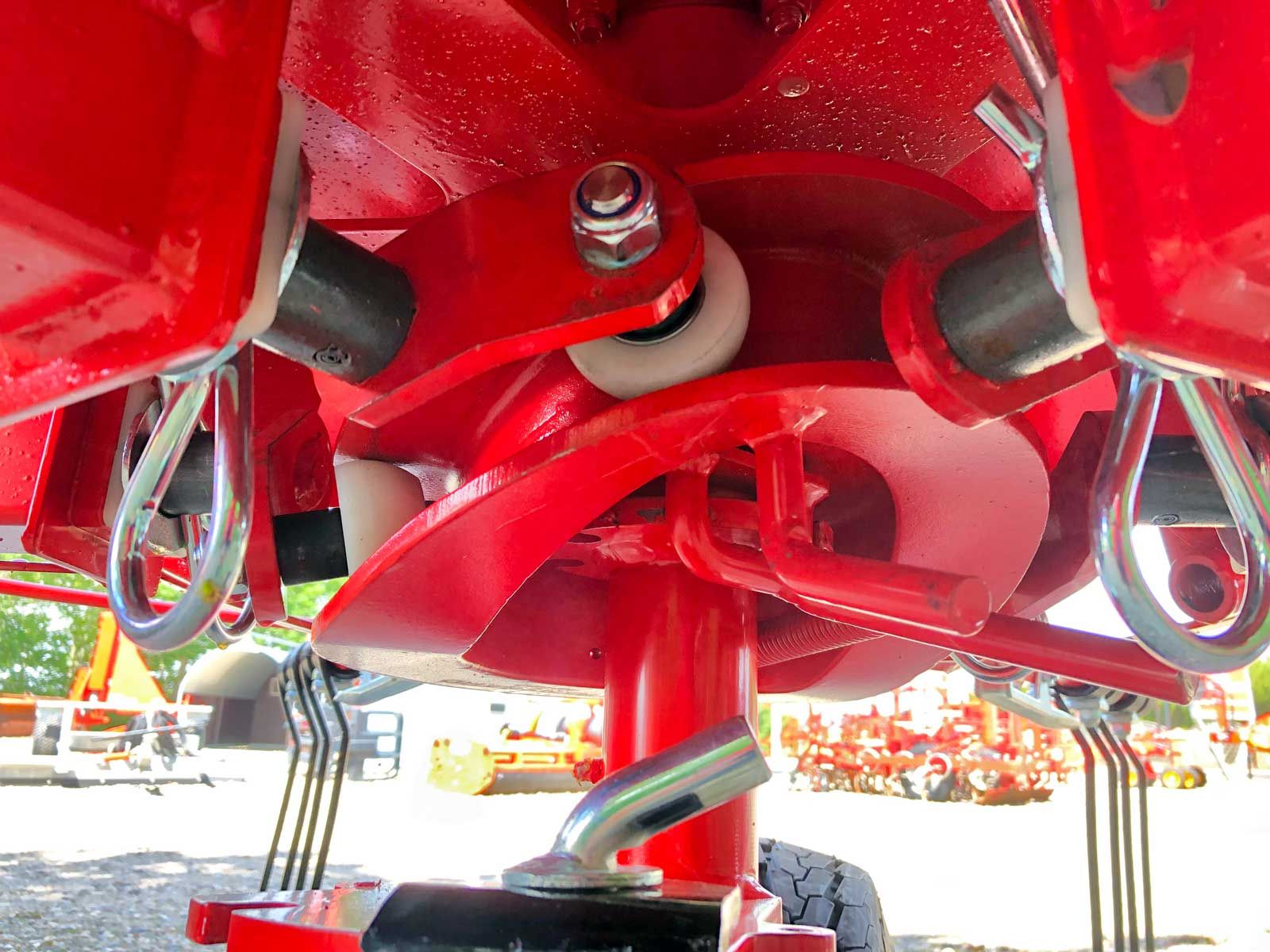

The TI-5000 rake has 2 rotors with 6 arms on each - all of which are fitted with nylon wheels. The closed ball bearings in the curve control require no lubrication. The arms are easy to remove via the spring-loaded handle when they need to be repositioned for the various work functions.

When switching from centre to side raking, the direction of rotation of the left rotor changes. It is important that the nylon wheel in the curve control is turned 180°. The model pivots between the suspension and the boom, which locks automatically when the machine is lifted.

During transport on roads, the machine is manually turned in behind the tractor.

Technical data

| Model: | TI-5000 |

|---|---|

| Working width | 3.6 - 4.2 m |

| Transport width | 2.5 m |

| Working positions | 3 pcs. |

| Rotor number | 2 pcs. |

| Rotor diameter | 195 cm |

| Number of raking arms per rotor | 6 pcs. |

| Number of rake springs per arm | 2 pcs. |

| Number of wheels (comes as standard with 2) | 2 / 4 pcs. |

| Tyre size | 16.5x6.5-8/6 ply |

| 3-point suspension | Cat II |

| PTO connector rpm | 400-540 |

| Power requirement kW/HP | 30 / 40 |

| Working speed km/h | 8-15 |

| Weight | 450 kg |