Roller Spreader STB-5000GA

Presentation

Fransgård's latest trailer spreader offers great possibilities for the customer who needs a large range with their spreader. The robust spreader box is hot-dip galvanised to extend the life of the machine. The model handles most bulk materials and the material flow is controlled via the hydraulic quantity adjustment valve.

The trailer-mounted spreader is fitted with large lorry wheels with a hydraulic brake, which is mounted under the box. The design provides the best weight distribution in relation to the spreader and tractor.

Lots of equipment - both standard and extra

The spreader box is developed and made based on many years of experience with lift suspended spreader boxes. The spreader comes with a stone release system, which consists of 28 spring clips that are only released exactly where the stone comes out.

A mechanical quick-emptying system is fitted as standard. Other standard equipment includes LED lights, warning lights, side lights on a rubber arm and step ladder. An eye hook is bolted to the machine as standard.

A tarpaulin with a hydraulic opening can be purchased as an option.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Technical data:

| Model: | STB-5000 GA |

|---|---|

| Working width | 236 cm |

| Transport width | 260 cm |

| Container, volume | 5000 L |

| Box dimensions, top | 247 x 195 cm |

| Height | 223 cm |

| Length w/towing | 350 cm |

| Consumption per km for 180g m² | 425 kg |

| Self-loading | No |

| Agitators | Standard |

| Roller diameter | 220 mm |

| Operation | Hydraulic |

| Oil quantity max. | 75 L. |

| Oil pressure max. | 210 bar |

| Wheels | 385/65R22.5-10 |

| Rims | 10 bolts |

| Weight | 1.460 kg |

Details:

Leaf springs

The powerful 38-piece leaf spring sets each consist of 4 stainless steel springs. They ensure optimal spreading of the material and can be infinitely adjusted via a spindle. Each set is mounted individually so that larger items can pass through without a large amount of material going out. The spindle can be completely detached if you want to empty the machine quickly.

Cylinder controlled opening of the tarpaulin

The 2 cylinders are mounted directly on the spreader box and are connected in series so that they lift the lid up and down simultaneously. The cylinders are throttled down, so everything happens at a leisurely pace. The tarpaulin cover is optional (item no. 3800)

Box design

The 5000 litre spreader box is made of Domex-420 steel and the whole box is hot-dip galvanised to ensure a long life. The design of the box ensures that the material is continuously fed to the agitator and roller, and that the box is completely emptied during the work.

Elevation kit

The elevation kit, which increases the volume of the spreader box by 3000 litres, is bolted together and bolted directly to the spreader box.

Important: Only spreaders from 2022 are prepared for fitting the elevation kit. The elevation kit is optional (item no. 3804)

Reinforcement

3 strong profile tubes inside the spreader box just above the agitator and 2 flat bars in the top of the box make it very stable in the box.

Contact warning light

The warning light at the rear of the spreader is activated manually on the switch above the right rear wheel of the spreader.

Chain drive

A solid 1" chain drive for operating the roller and agitator, via the powerful hydraulic motor and with a chain wheel tensioner, ensures optimal and reliable operation of the spreader.

Lights

High-tech LED lights include a rear light, a turn signal and an integrated reflective triangle. Yellow hazard warning lights and a rubber arm with trailer lights, with a yellow light on the side, a red light at the rear and a white light at the front, are standard.

Agitators

A powerful agitator with angled blades ensures optimum treatment of the material so that the roller receives a constant supply of material.

Ladder

At the back of the spreader box is the integrated ladder, which is mounted underneath the box and which is easily removed if the box needs to be inspected from the inside. 2 Stop blocks for the wheels are also mounted back at the back of the box.

Mounted towbar

The towbar is mounted on the heavy flange with large visible bolts, so it is easy to continuously retighten them.

Towing arm

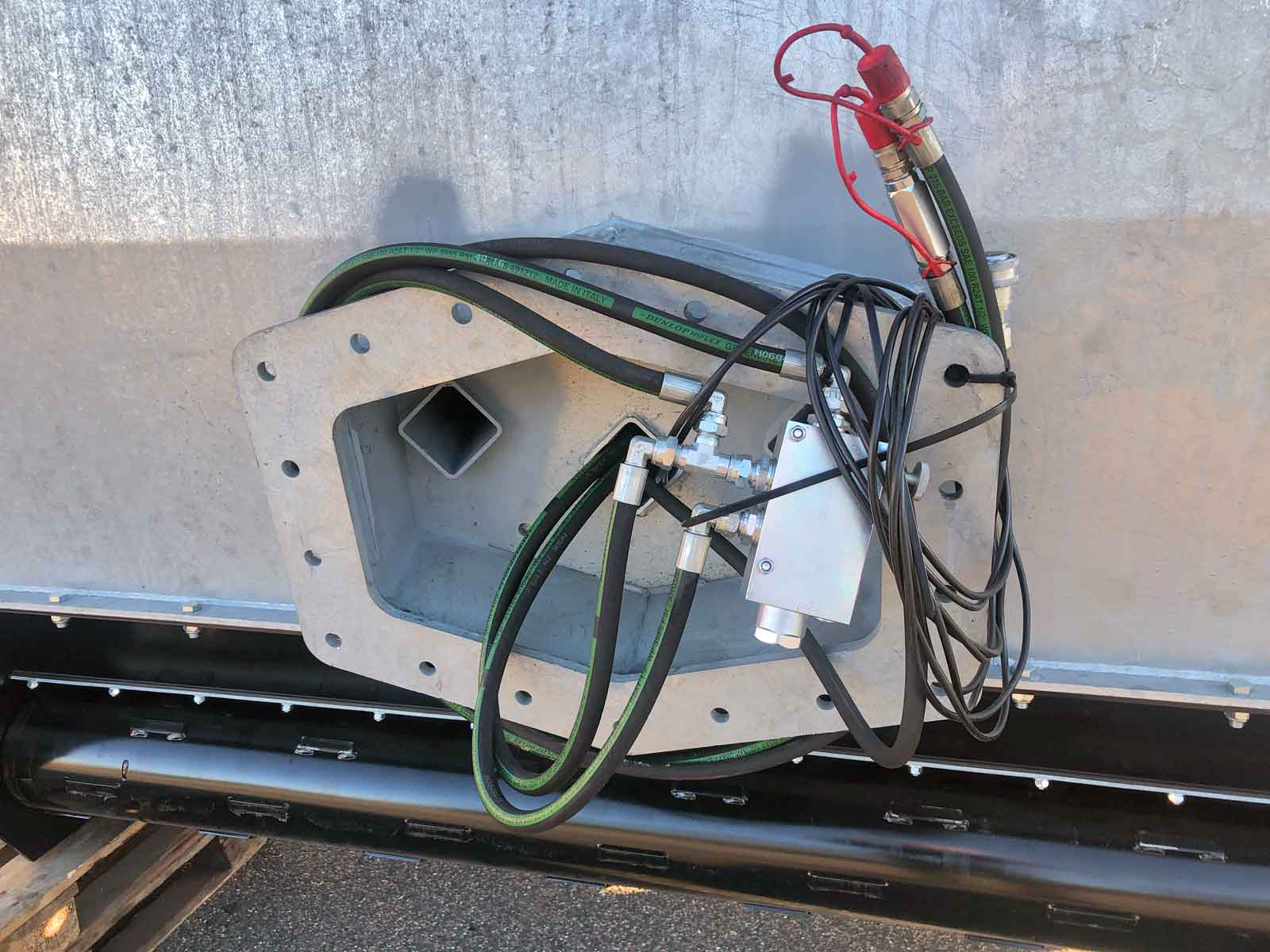

The 180 cm long towing arm with built-in support foot safely shields the hydraulic hoses, lines and valve block from damage during operation of the spreader. The towing arm has a service hole on top, so it is easy to get to the quantity control valve block.

Towing eye

The towing eye is bolted on and can be mounted at different heights. The pivoting towing eye makes the spreader follow the terrain as well as possible and ensures that if the spreader should tip over, the towing eye turns freely so that the tractor does not tip over too.

Roller

The Ø220 mm roller with welded knobs in a spiral design ensures even spreading of the material. The roller is fitted with 2 heavy duty rubber screens. The rubber screen ensures that only the desired amount of material escapes.

Valve block

The roller quantity control valve block is fitted with a stainless steel adjustment knob and a non-return valve on one hydraulic hose, which ensures that the roller does not turn the wrong way around and runs at the desired speed.

Wheels

Large pneumatic rubber wheels mounted on 10-bolt rims ensure a reliable and stable spreader while being approved as a spreader with an elevation kit. The tyres can also be spiked.

Wheel axle

The heavy-duty wheel axle with a 10-bolt hub and hydraulic brakes is rated to 40 km/h.

Side guards

The heavy-duty side guards on both sides are made of 5 mm hot-dip galvanised steel plate and protect both the chain drive and flanged bearings from damage. Turn the guard outwards slightly when the parts need to be lubricated.

Optional extras:

Item No. 3800

Hydraulically opening tarpaulin cover can be retrofitted to both the spreader box and the elevation kit.

Item No. 3802

Resistor for mounting on the light cable if the LED light flashes when connected.

Item No. 3804

Elevation kit for the spreader box +3000 litres. The set is bolted on top of the spreader box.

Applies to the 2022 model and newer.

Download PDF files

See our information material here, where you can also read it online, print or download the files.