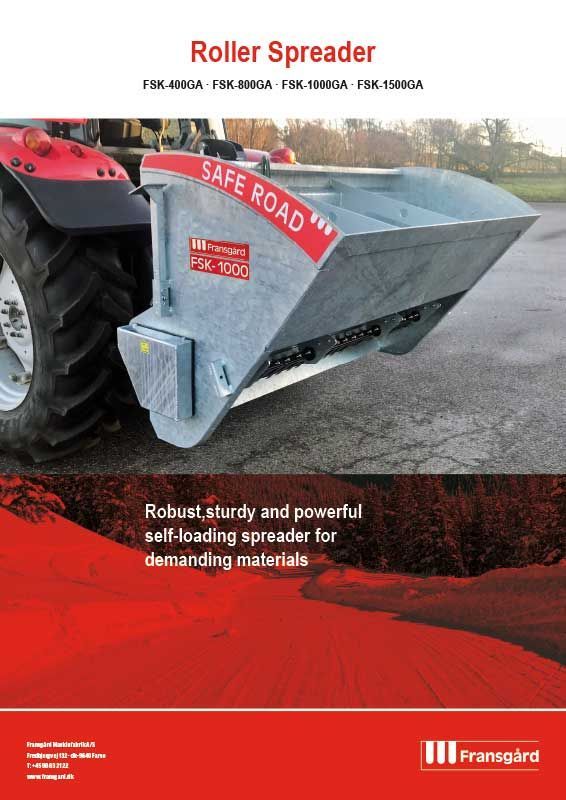

Roller Spreader FSK-400GA · FSK-800GA · FSK-1000GA · FSK-1500GA

Presentation

Fransgård's self-loading spreaders with roller feeders are robust, reliable and with many appealing details. The models are produced in many sizes and therefore you can find a model that exactly fits your need for spreading coarse sand, sand/salt, fine gravel or similar material.

Each model in the series is also available in a galvanised version (GA). Galvanisation extends the lifetime considerably, especially when salt is used.

High-strength steel and other good materials

The spreader box is made of high strength steel (Domex 420) with wear steel on the top and bottom. Each model is fitted with a hydraulic engine with a powerful chain drive for operating the roller fitted with spiral-shaped knobs and an agitator that ensures uniform spreading of the desired spreading material. The roller also has a stone remover and empties quickly. New stone release system with finger springs ensures that larger stones are easily removed while only minimal additional spreading material is released.

With the many different types of suspensions for the spreaders, a flexible installation adapted to individual needs is achieved (see under optional extras). The models can, as an optional extra, be fitted with quantity control, either as hydraulic- or electrically controlled. With this feature you can reduce the amount of spreading material consumed and save money.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Technical data:

| Model: | FSK-400GA | FSK-800GA | FSK-1000GA | FSK-1500GA |

|---|---|---|---|---|

| Working width | 120 cm | 150 cm | 200 cm | 230 cm |

| Transport width | 145 cm | 175 cm | 225 cm | 255 cm |

| Container volume | 400 L | 800 L | 1000 L | 1500 L |

| Box dimensions, top | 120 x 75 cm | 150 x 98 cm | 200 x 98 cm | 230 x 98 cm |

| Stone remover | Standard | Standard | Standard | Standard |

| Fast emptying | Standard | Standard | Standard | Standard |

| Self-loading | Possible | Possible | Possible | Possible |

| Hydraulic connectors | 1 double | 1 double | 1 double | 1 double |

| Agitators | Standard | Standard | Standard | Standard |

| Hydraulic quantity control | Possible | Possible | Possible | Possible |

| Electricity-controlled quantity regulation | Possible | Possible | Possible | Possible |

| Suspension | Bolts on | Bolts on | Bolts on | Bolts on |

| Weight w/o suspension | 265 kg | 350 kg | 463 kg | 510 kg |

Details:

3-pin connector

Electric control box item no. 3680 (optional extra) is connected via a 3-pin connector.

Electric control box

The Electric Control Box 3680 (optional extra) allows you to quickly set the desired flow rate and have a good overview of the amount you are spreading.

Springs

The many 3-part stainless steel leaf springs provide uniform pressure on the rubber screen, ensuring optimum spreading of the material. The many springs are mounted individually and act as stone remover devices, allowing larger stones or lumps to escape without losing large amounts of material.

Spring boom

The heavy-duty profile from which the spring boom is made is Aqua Coated and fitted with stainless springs to ensure a long life in the harsh environment in which you work.

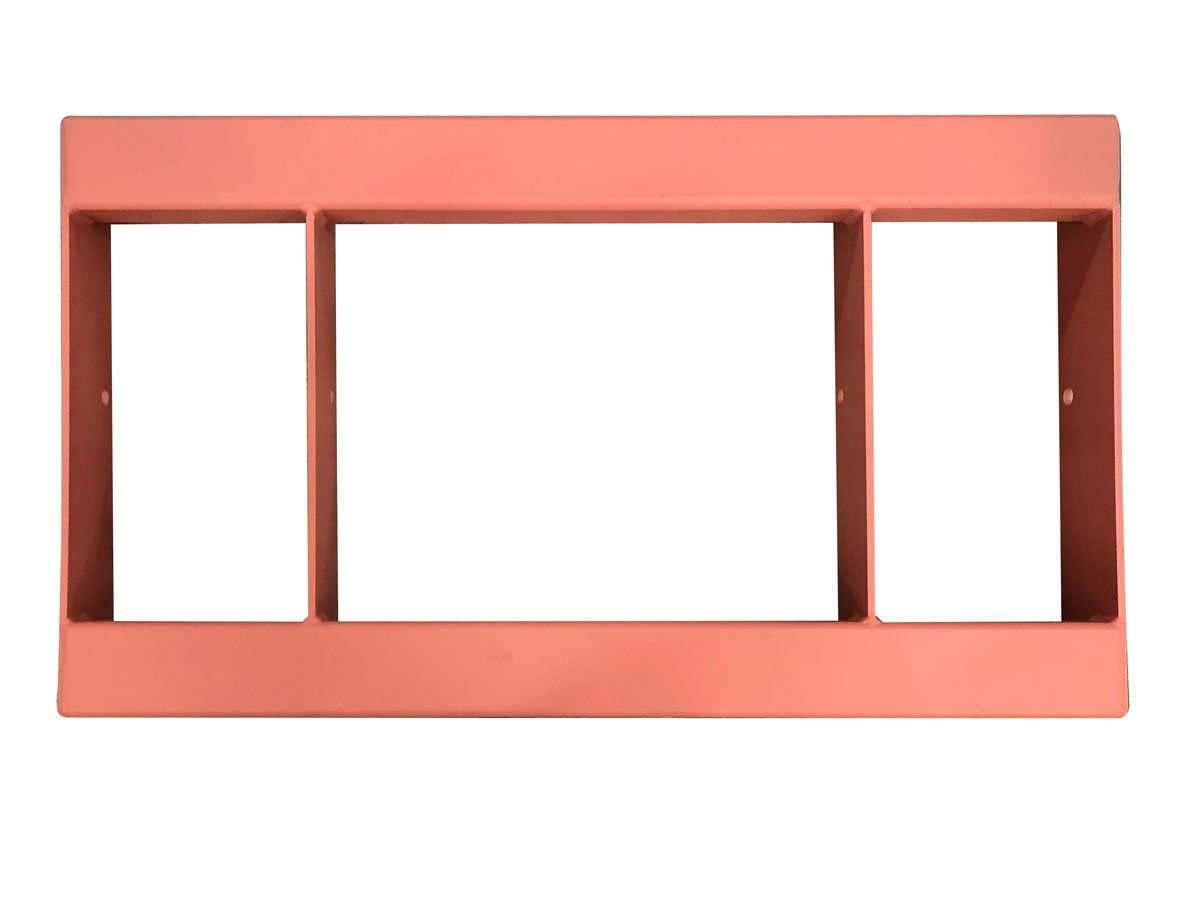

Front plate

The front plate is reinforced by the top being bent around and welded together with 4 flat bars, which stand on end and are used to mount the desired suspension.

Reinforced box

The box of the FSK spreaders is reinforced all around with an extra steel edge both at the top and bottom.

Reinforcement at the bottom

The reinforcement at the bottom of the box is outward facing, so that the working width of the machine is not compromised.

Holder for the support leg

The support leg is easily lifted and secured in the holder during work, so you always have the support leg with you when you need to park the leveller again.

Holes, valves

The spreader is prepared for the installation of hydraulic volume control (optional extra).

Handles

The handle for pressing the rubber cover can be set in 4 positions, depending on the type of material to be spread, as well as the position for quick emptying.

Internal reinforcement

The inside of the spreader box is reinforced with vertical flat bars at the top for stability - even when loading the machine.

Box design

The design of the spreader box provides a compact machine that sits close to the tractor but can still be used as a self-loader. All spreader boxes are hot-dip galvanised.

Non-return valve

The non-return valve on one hydraulic hose ensures that the roller does not run the wrong way round.

Chain drive

The powerful chain drive with ¾" chain and hardened gear, as well as a gear wheel for tightening the chain, ensures high reliability.

Chain guard

The chain guard is Aqua Coated and fitted with an edging band for the best protection and longer life of the chain drive.

Bed screen

The screen above the bed is Aqua Coated, which provides good protection and long life.

Oil engine

The powerful oil engine for operating the roller and agitator is fixed with a bracket to ensure stability - even under a heavy load on the engine.

Agitators

The strong 6-edged agitator with angled blades ensures optimal feeding of the roller and is Aqua Coated for long life.

Self-loading, left

The spreader boxes on all 4 FSK models can be used as self-loading.

Guard for the oil engine

The guard over the oil engine provides optimal protection for the oil engine and the gaurd is Aqua Coated to ensure long life.

Support legs

The support legs with the large foot are easily fitted without using tools and ensure safe and stable parking.

Design, internal

The internal design of the spreader box ensures even and optimal feeding of the roller and total emptying of the box every time.

Roller

The roller has mounted knobs that spiral around the pipe to provide a uniform spread of material over the entire working area. The roller is Aqua Coated for long life.

Optional extras:

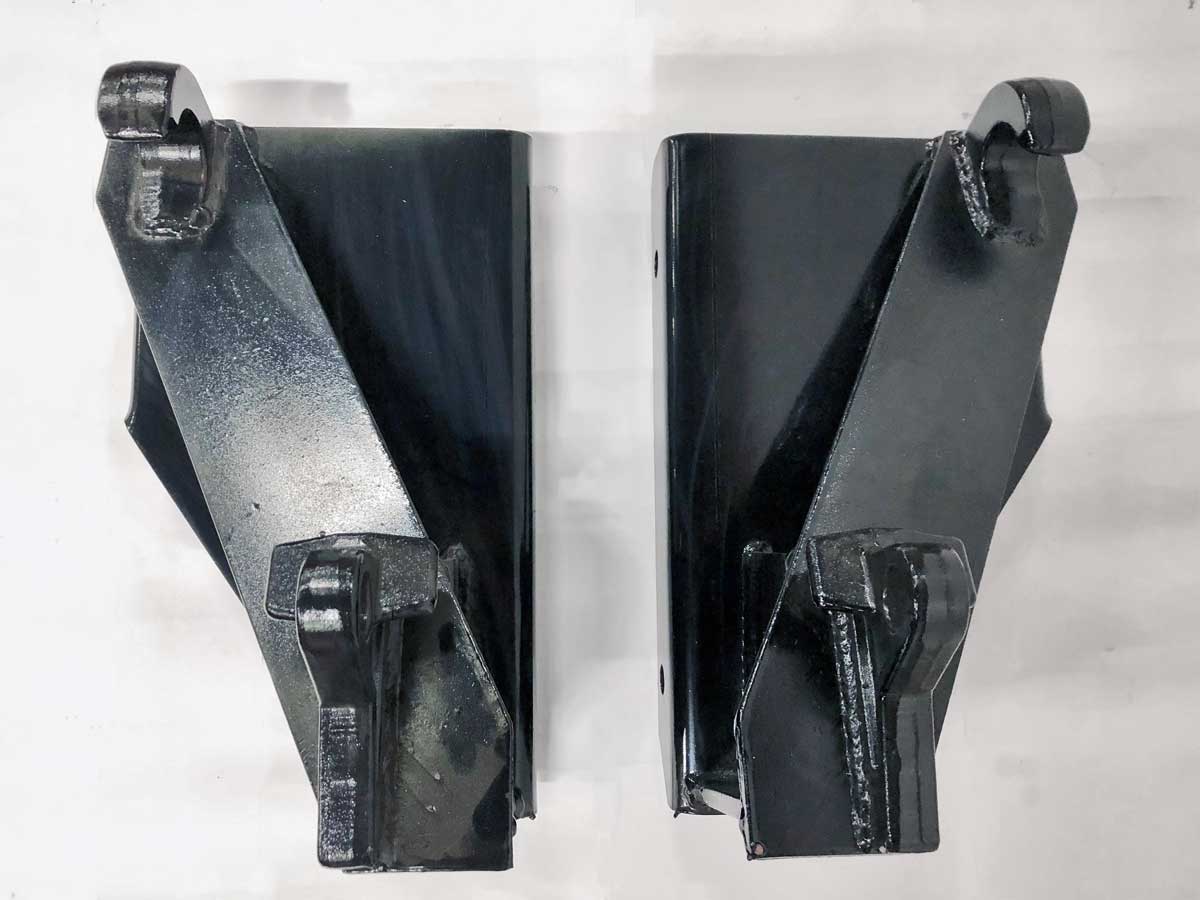

Item no. 3618 3619

Hydraulic cylinder for mounting on 3-point suspension, so the machine can be used as self-loading. (3619 fits FKS-400/800/1000) (3618 fits FSK-1500GA)

Item No. 3624 3625

Hydraulic quantity control to control the speed of the auger.

(3624 is for 3/8" hydraulic hoses) (3625 is for ¾" hydraulic hoses)

Item No. 3617

50 cm blanking plate for limiting the spreading width. Mounted with bolts.

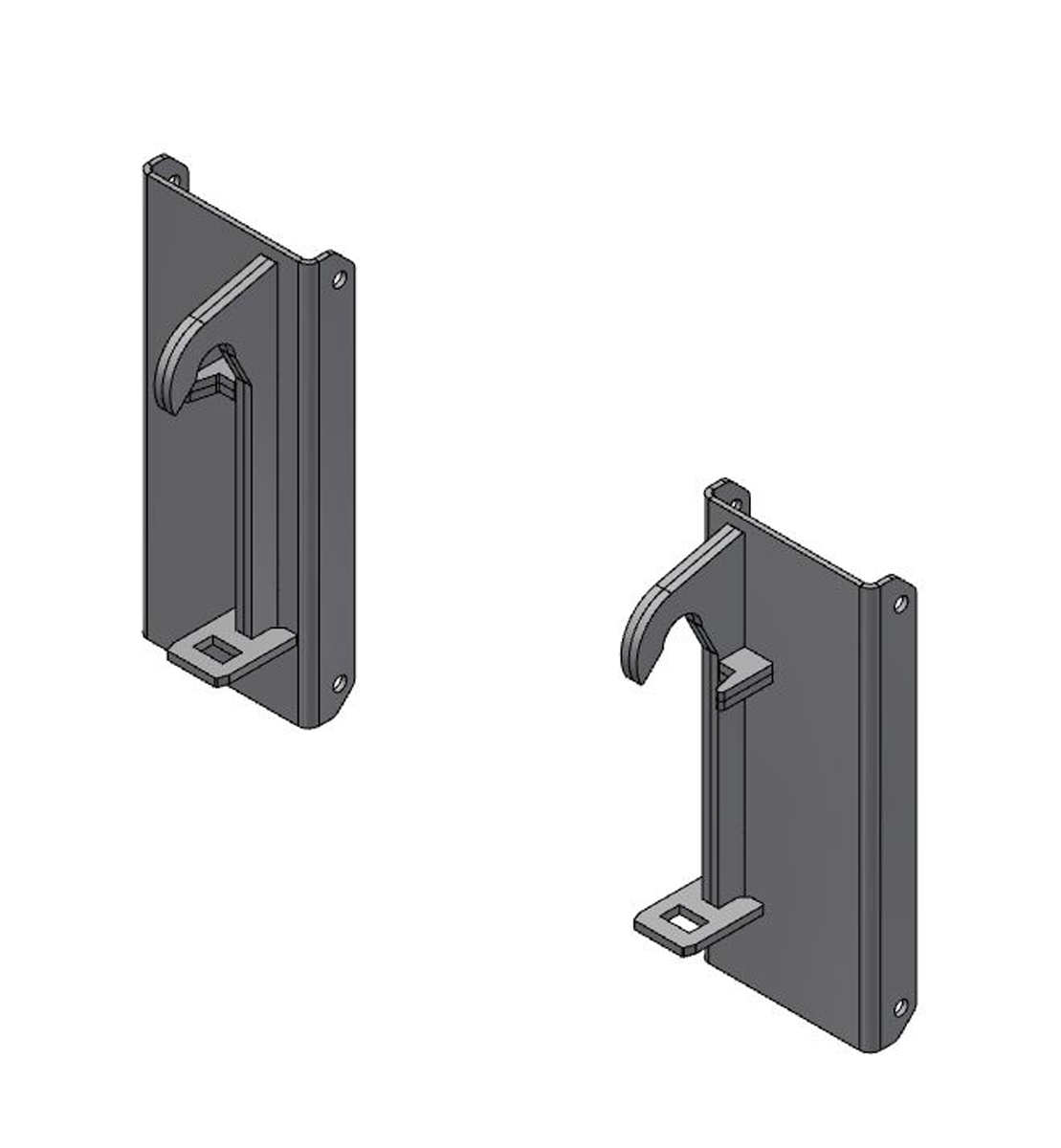

Item No. 3636 3642

The SMS suspension is bolted on.

3636 for FSK-400

3642 for FSK-800/1000/1500

Item No. 3637 3647 3730

3-point suspension is bolted on.

3637 for FSK-400

3647 for FSK-800/1000

3730 for FSK-1500

Item No. 3654

JCB/ZL604 suspension bolts on

FSK-800/1000/1500

Item No. 3632 3644

EURO suspension bolts on

3632 for FSK-400

3644 for FSK-800/1000/1500

Item No. 3635

The SMS suspension bolts on.

FSK-400

Item No. 3639

Suspension for welding of fasteners bolts on (supplied primed)

FSK-400

Item No. 3641

A-frame suspension bolts on

FSK-800/100/1500

Item No. 3650

HMV suspension bolts on

FSK-800/1000/1500

Item No. 3652

Suspension for welding of fasteners bolts on (supplied primed)

FSK-800/1000/1500

Item No. 3740

Volvo BM suspension bolts on

FSK-800/1000/1500

Item No. 3660 3662 3664 3666

Safety bars for mounting over the agitator to prevent foreign bodies entering the machine. Bolts on.

3660 for FSK-400

3662 for FSK-8000

3664 for FSK-1000

3666 to FSK-1500

Item No. 3672 3674 3676 3678

The shaped tarpaulin has a strong elasticated edge that makes it quick to attach and detach, and at the same time ensures that the material stays dry.

Download PDF files

See our information material here, where you can also read it online, print or download the file.