PC-2000-SEH Wood Chipper

Presentation

This tractor-mounted pellet wood chipper, PC-2000-SEH, can handle tree trunks up to 20 cm in diameter. The chipper is manually fed through the large feed hopper. Its robust main frame ensures stable and reliable chipping.

This is a strong solution for users who simply need to convert wood into chips without specific quality requirements for the chips.

Focus on Efficient Functionality and Safety

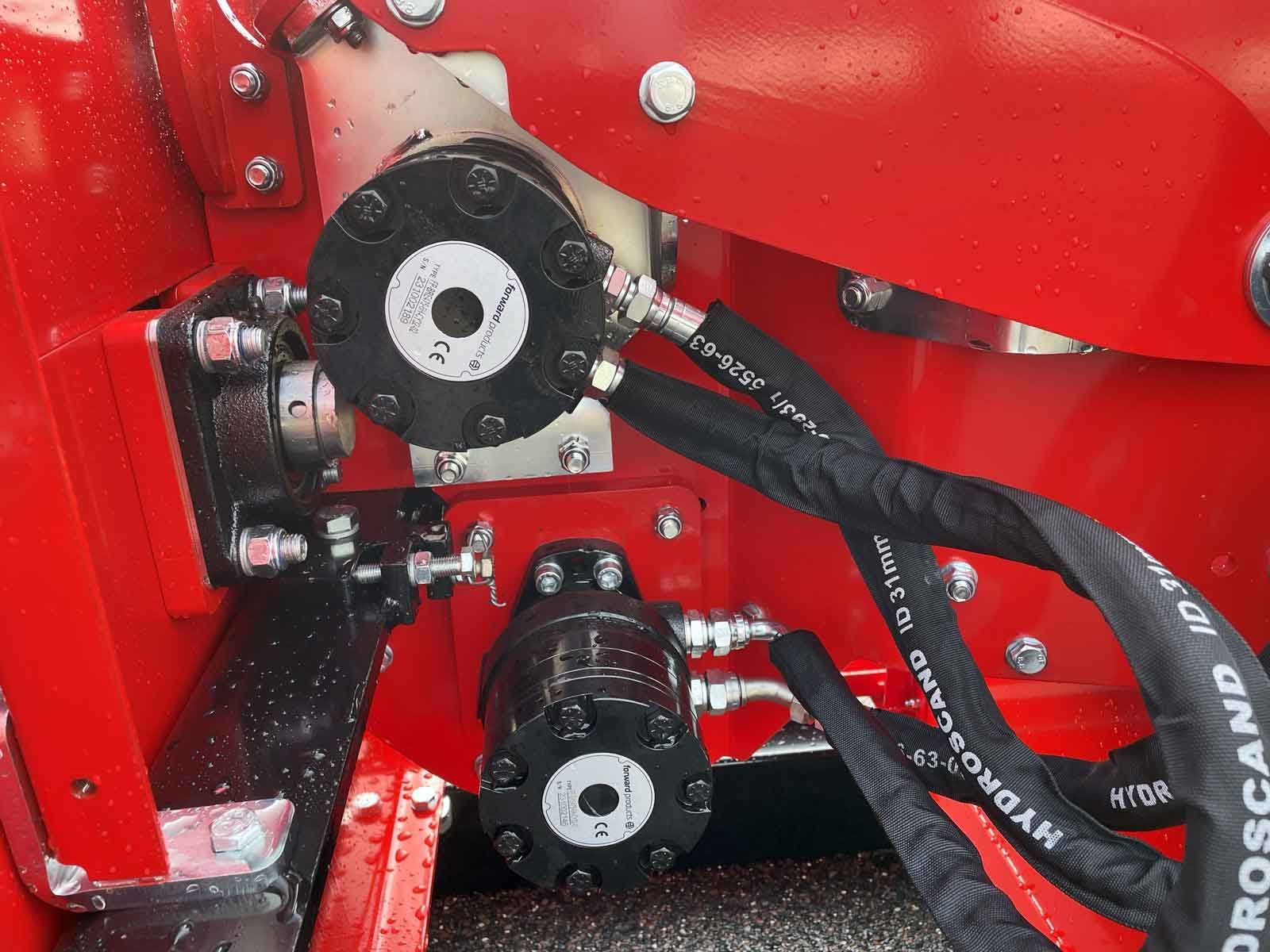

Each feed roller is powered by its own hydraulic motor, with feed speed infinitely adjustable to suit requirements.

Along the edge of the feed hopper, a safety bar is mounted that stops the feed rollers when pressed. For additional safety, two emergency stop buttons are positioned on each side of the hopper to stop the machine in case of an emergency.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Technical Data

| Type | Wood chipper for manual feeding |

|---|---|

| Max. tree diameter | Ø20 cm / Ø8in |

| PTO speed | 540 / 1,000 rpm |

| Power requirement (540 rpm) | Max. 45 kW / 61 HP |

| Power requirement (1,000 rpm) | Max. 85 kW / 115 HP |

| Spline on main shaft | 1 3/4” x Z6 |

| Weight | 950 kg/ 2094lb |

| Mounting | 3-point tractor mount |

| Hydraulics | From tractor |

| Number of feed rollers | 2 |

| Feed roller torque | Up to 1,096 Nm |

| Capacity (*) | 20m³ per hour / 24yd² per hour |

| Crane mounting option | No |

| Speed monitor | Optional |

| *Capacity depends on knife settings, available horsepower, wood condition, and rotor speed. |

Details

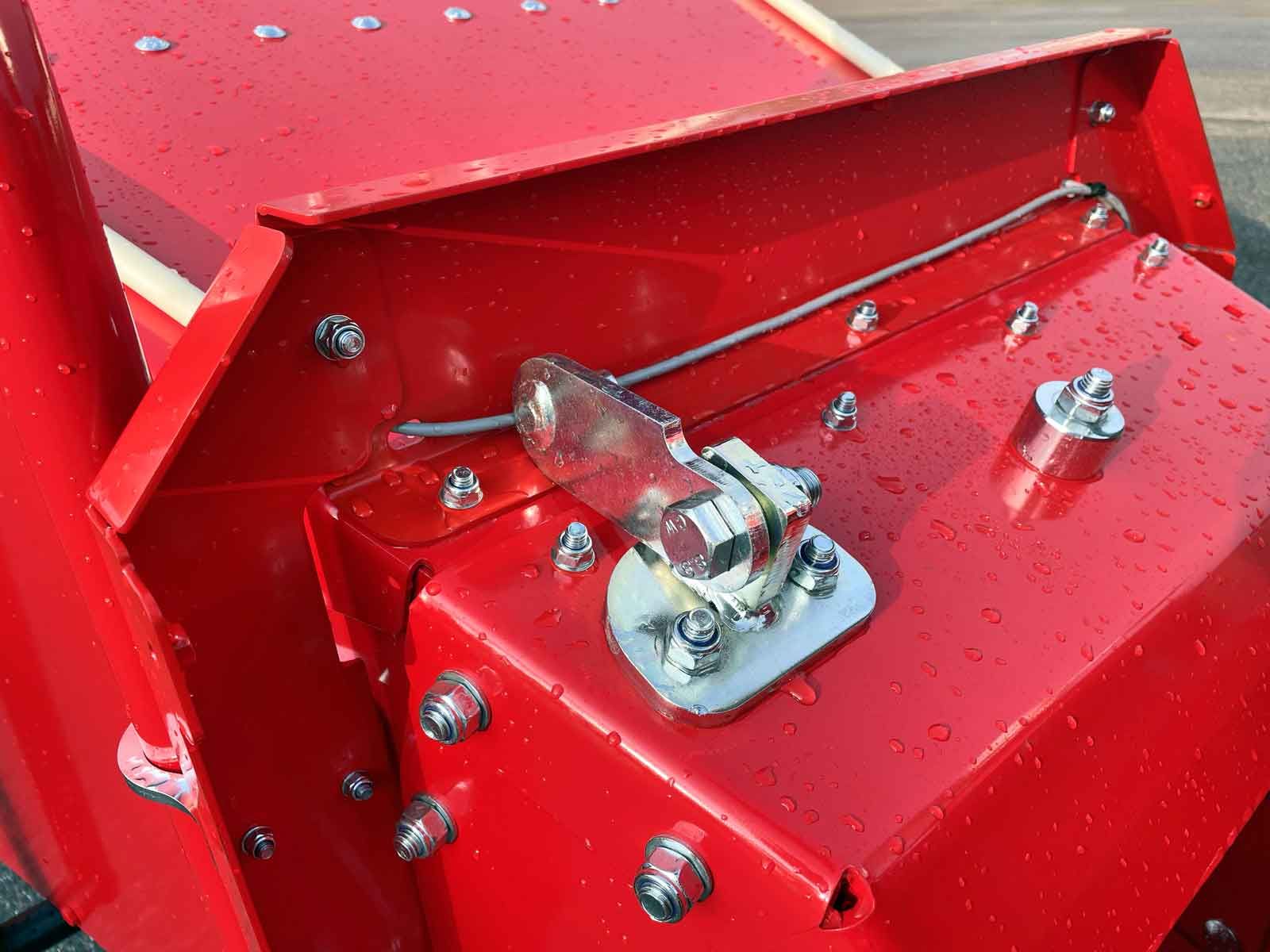

3-Point Mounting

The sturdy 3-point mounting ensures secure attachment to the tractor.

Main Frame

The robust main frame provides a stable and strong structure, increasing durability.

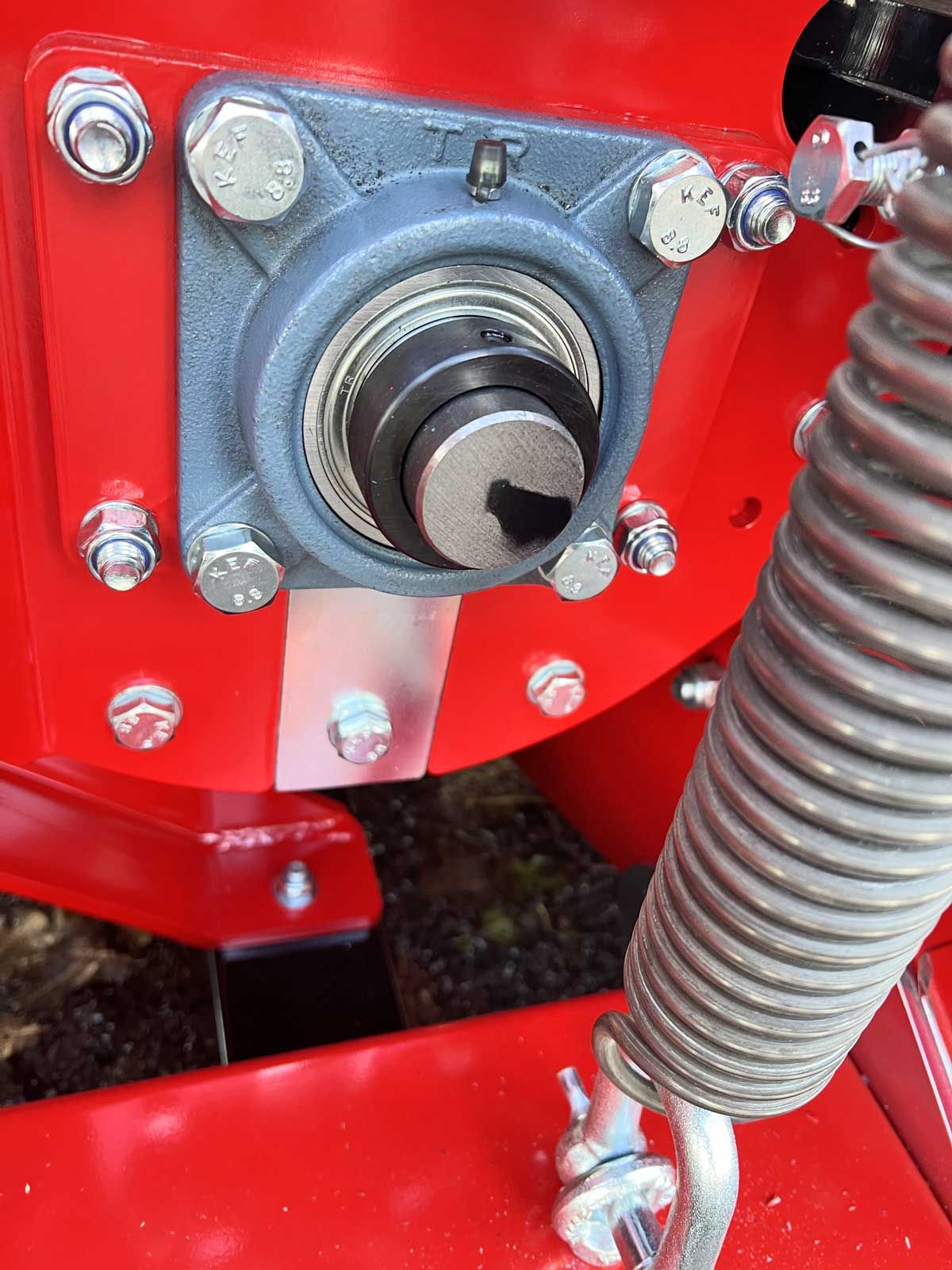

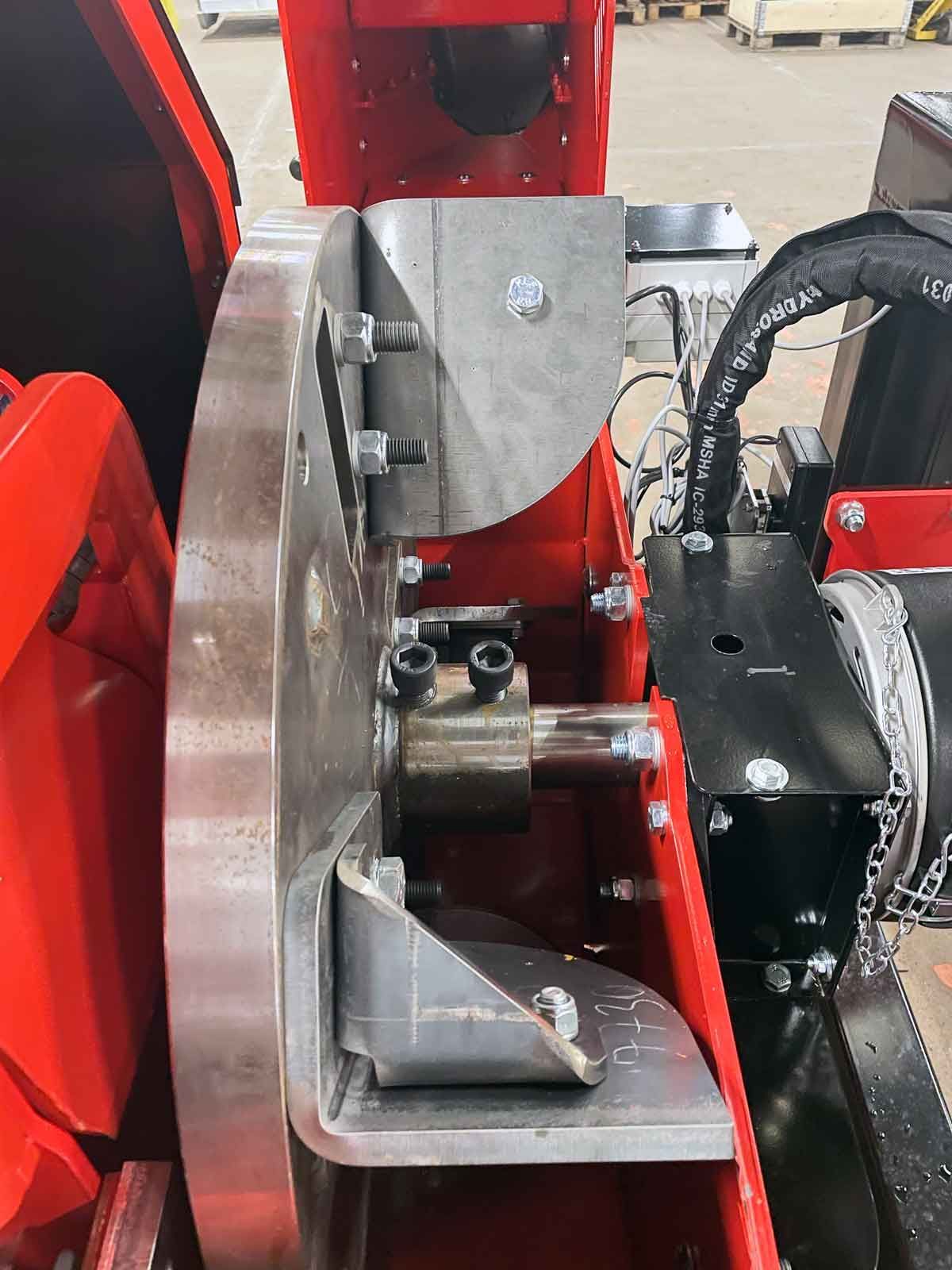

Flange Bearing

The heavy-duty flange bearing ensures stable operation.

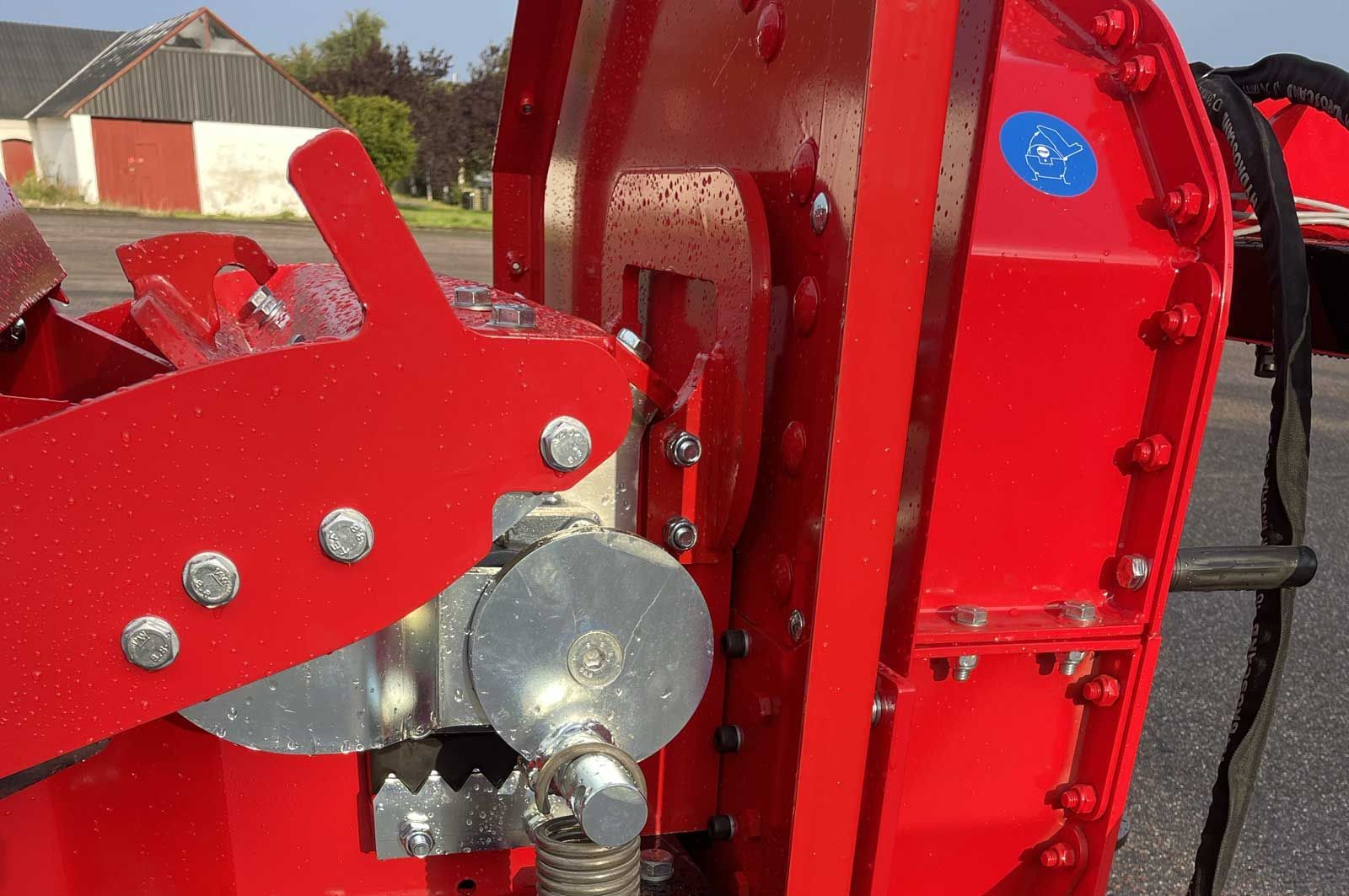

Emergency Stop

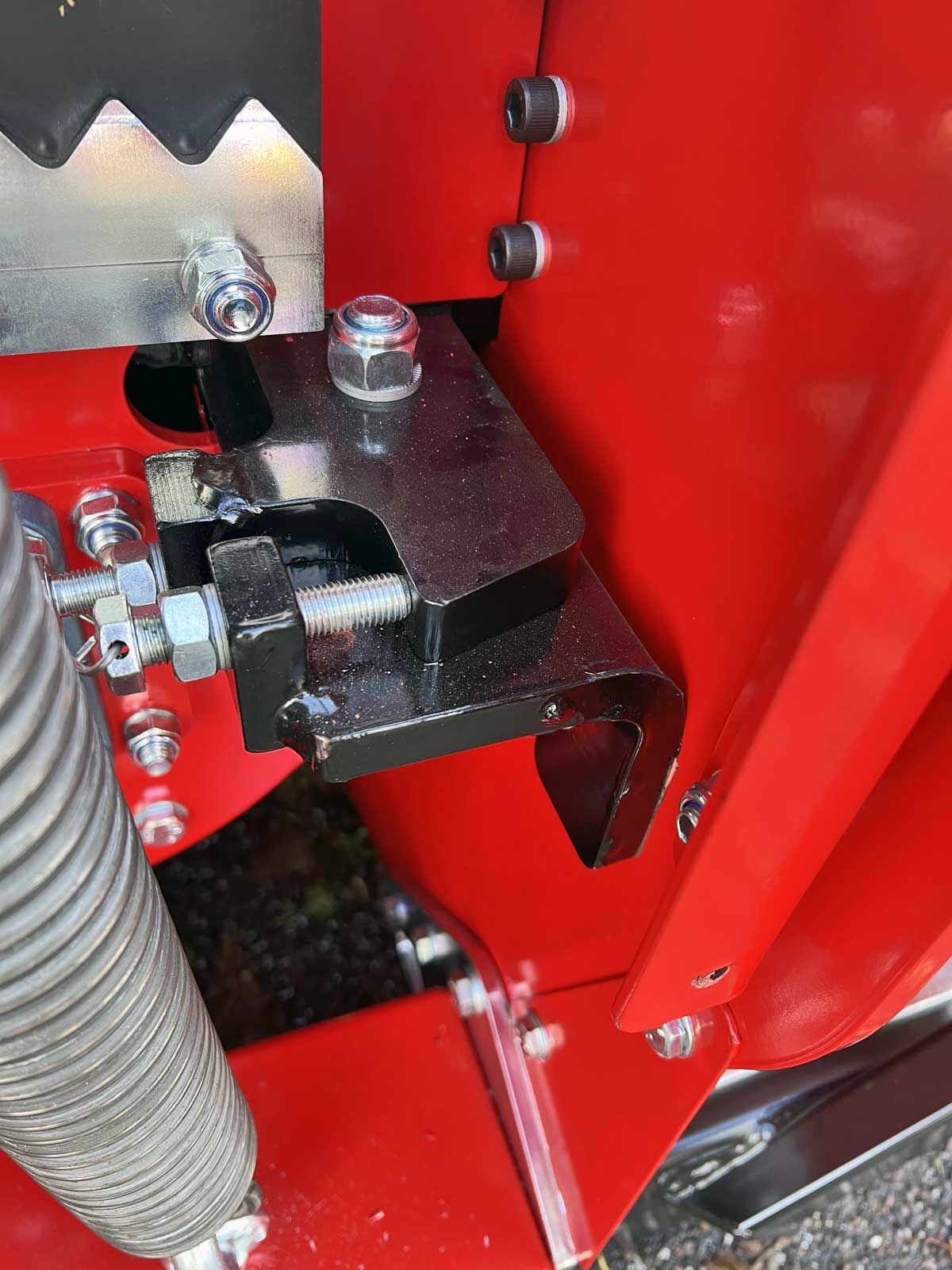

Visible emergency stop buttons allow quick stops in critical situations.

Safety Frame

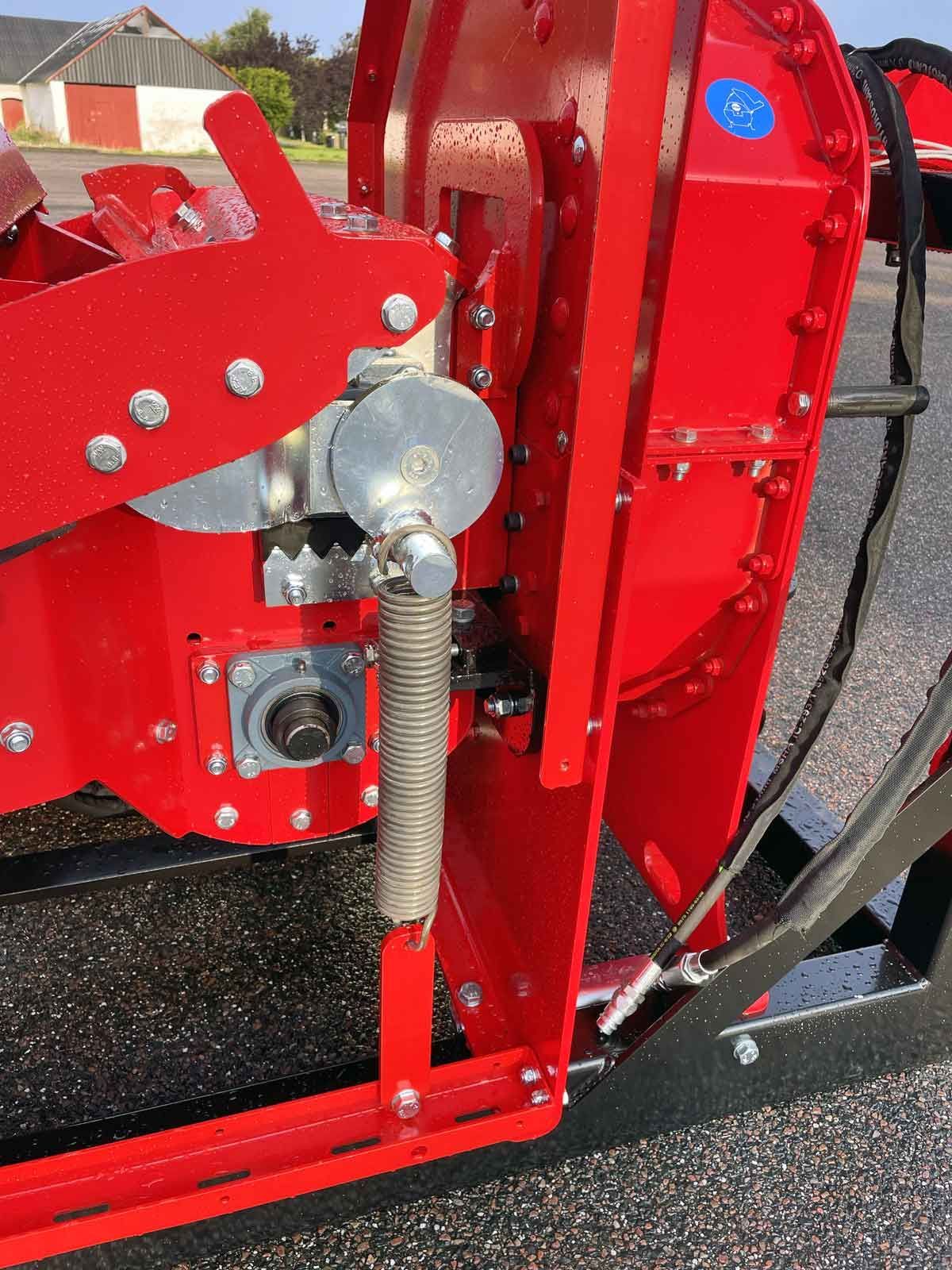

The feed roller stops when the frame is pressed against the hopper.

Release Bracket

The bracket keeps the safety grille in place during operation but moves into a stop position when pressed into the hopper.

Warning Symbols

Symbols enhance safety awareness during machine use.

Reset Button

When the reset button glows blue, the machine has stopped due to the safety system. To restart, press the reset button, and the light will turn off.

Swivel Spout

The spout can be rotated in selected intervals using a stainless steel handle.

Adjustable Top Flap

The top flap holder allows adjustment of the chip output angle.

Handle

The handle on the rotor housing lid makes opening and closing the lid easy.

Rubber Suspension

The heavy-duty rubber suspension dampens vibrations.

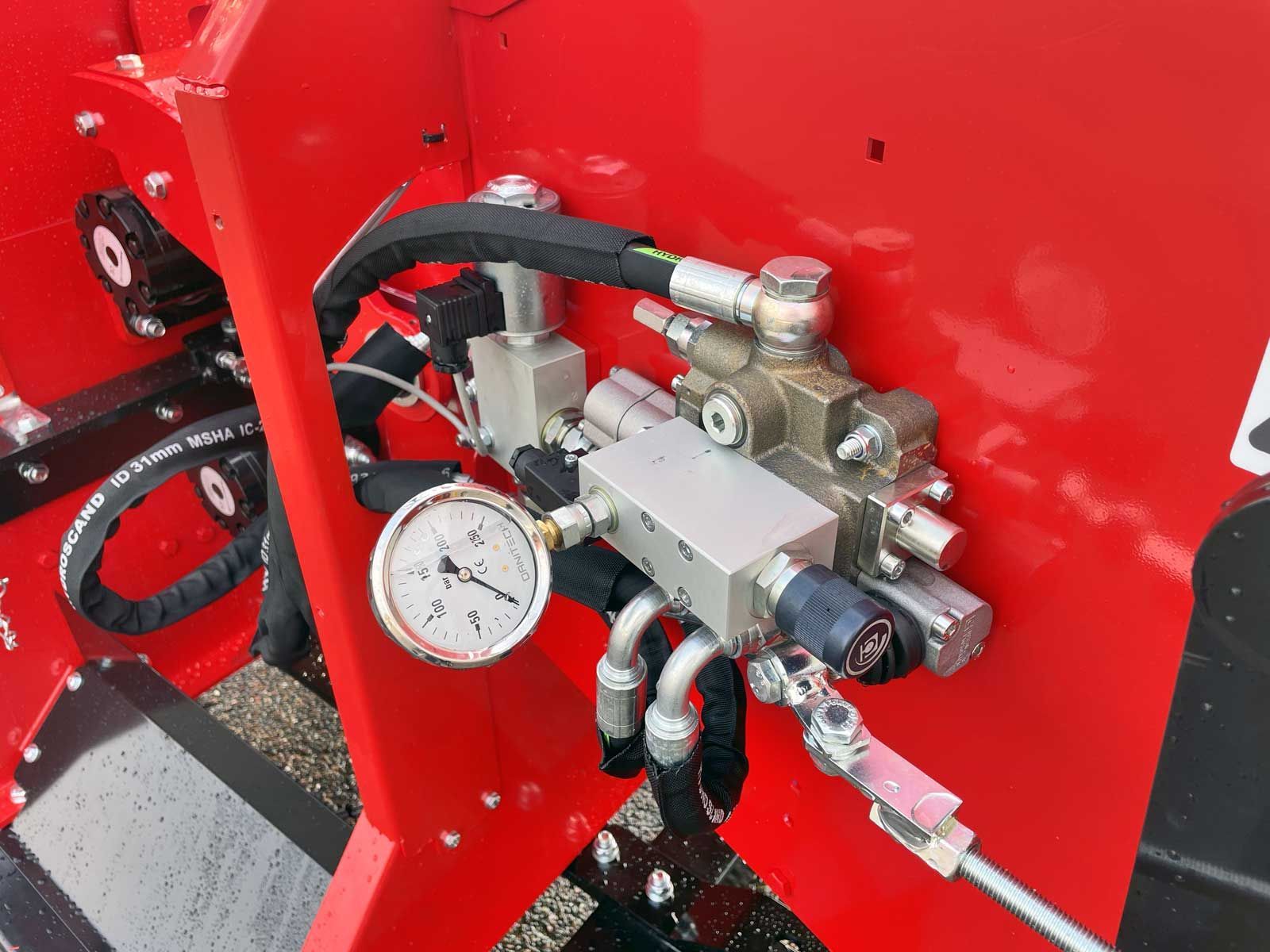

Adjustment Valve

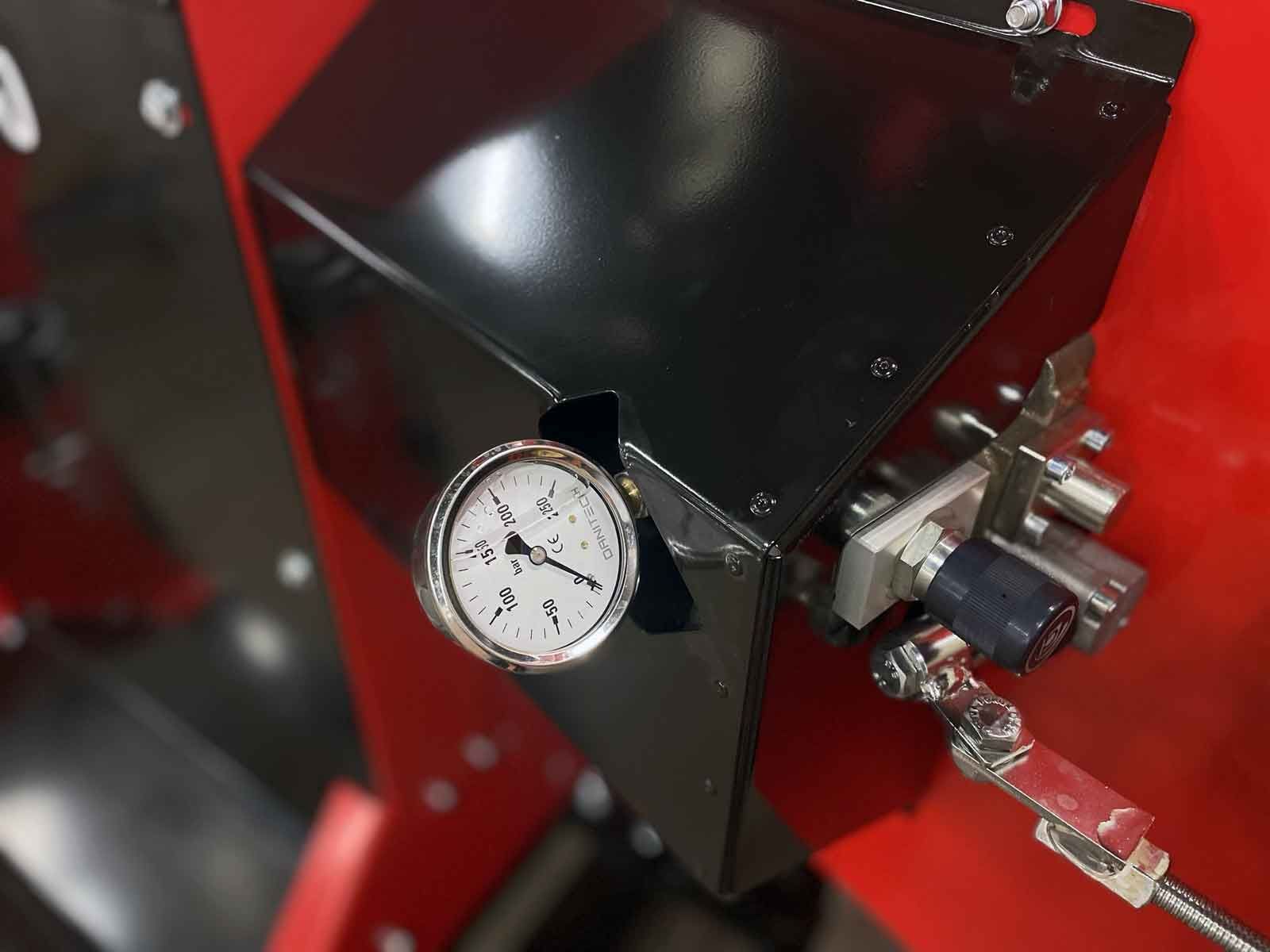

The adjustment valve ensures consistent hydraulic pressure to the feed rollers.

Robust Rotor Housing

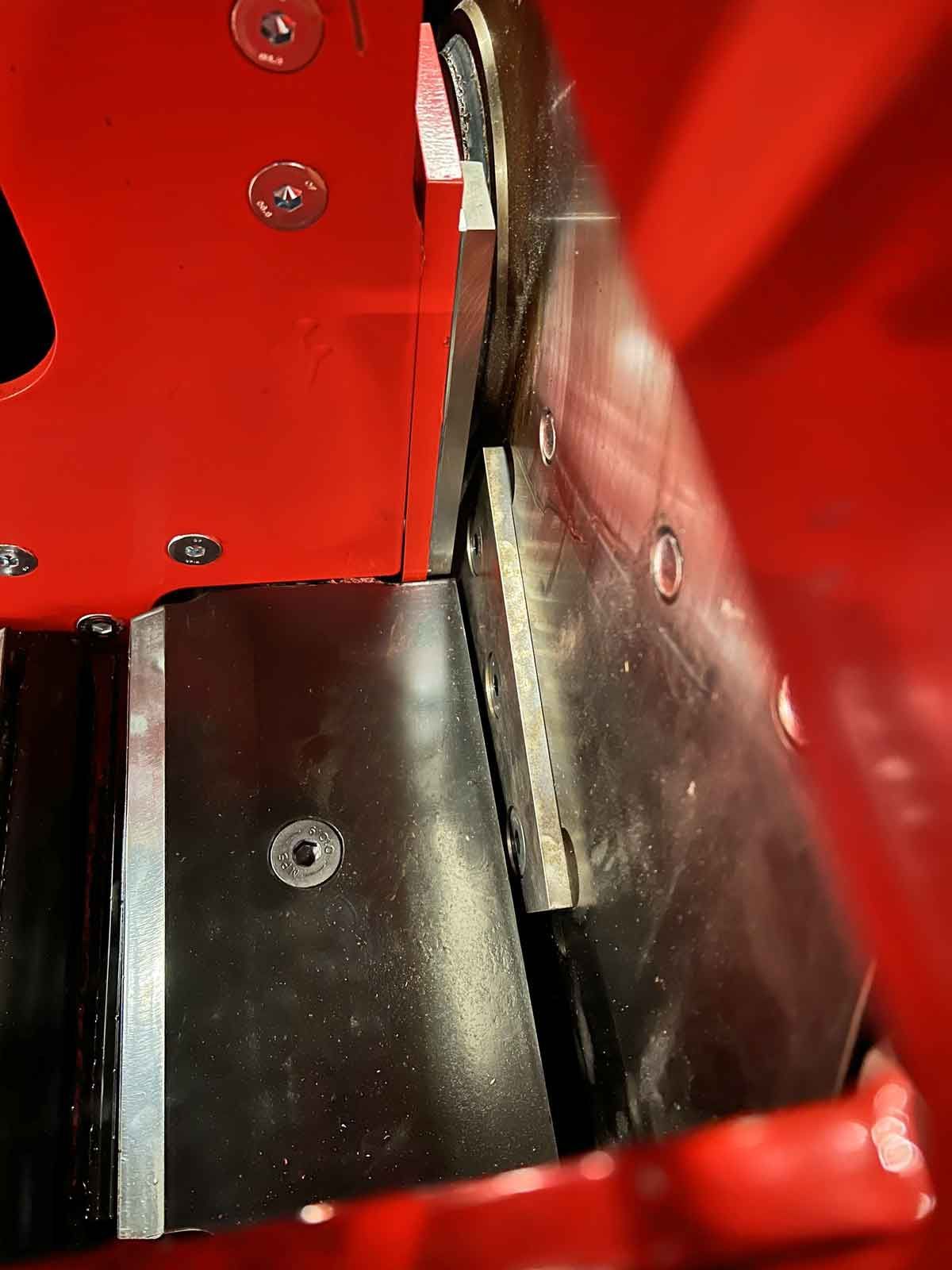

The solid rotor housing ensures an efficient workspace for the cutting wheel and blades.

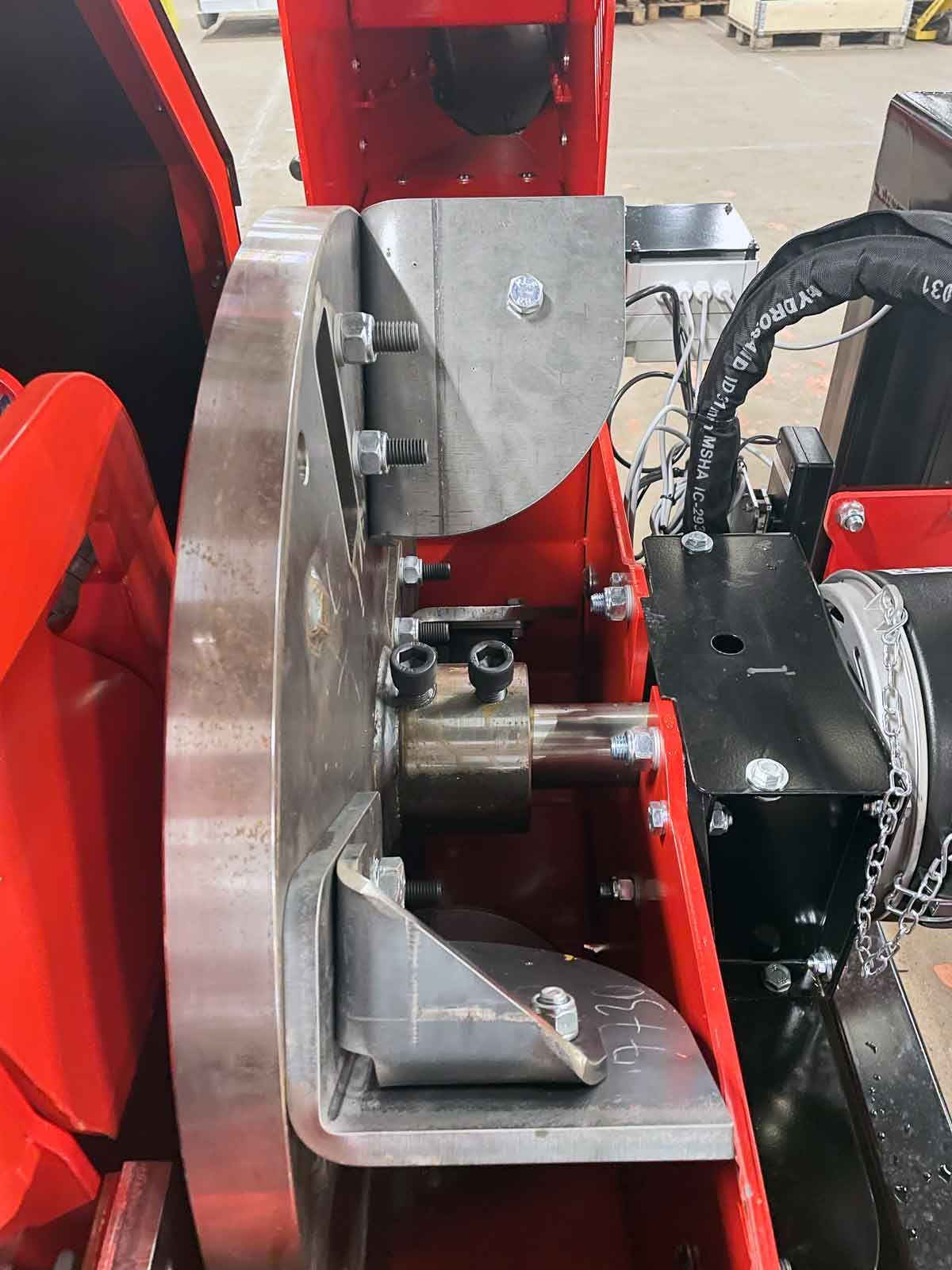

Cutting Wheel

The heavy cutting wheel is the foundation of an efficient workflow.

Chipping Blades

Four sharp, durable chipping blades are mounted on the cutting wheel.

Counter Blades (Bottom and Side)

Bottom and side counter blades hold the material in place, ensuring the desired chip size.

Counter Blades Side

Side counter blades hold the material in place, ensuring the desired chip size.

Feed Roller Release Rod

Used to access the feed rollers, the rod is stored on the machine for easy access.

Service Cover

The rotor housing cover is secured with sturdy bolts for easy removal during maintenance.

Stainless Steel Latch

The latch secures the feed roller cover and is released when the cover needs to be opened.

Hydraulic Oil Motor

The feed rollers are powered by a solid hydraulic oil motor.

Tow bar

The tow bar allows a trailer to be attached to the chipper. A bolt with a split pin prevents detachment during rough terrain driving.

Pressure Gauge

The gauge shows the current hydraulic pressure.

Steel Bearing

The rotor is mounted on a heavy-duty steel bearing designed to handle high workloads.

PTO Shield

The large, solid PTO shield provides optimal protection. It can be easily removed with two fasteners for quick access during attachment and detachment.

PTO Holder

The stainless steel PTO holder ensures protective storage when the wood chipper is not in use.

Rotor

The rotor weight of approximately 380 kg ensures smooth operation, with the rotor's inertia facilitating efficient wood chipping without relying solely on the tractor's power.

Discharge Wing

Mounted on the rotor side, the discharge wings help eject finished chips through the spout.

Accessible Feed Rollers

Easy access to rollers and feed mechanism during maintenance.

Rotor Lock Pin Installation

The lock pin prevents unintended rotor rotation during service or inspection.

Rotor Lock Pin Storage

The pin is stored in its holder during operation, transport, or storage.

Feed Roller Spring

The heavy spring keeps the feed rollers in the optimal working position.

Horizontal Feed

The horizontal twin-feed rollers ensure a robust structure and strong grip on the wood. The adjustable feed speed allows for smooth and controlled operation.

Heavy-Duty Feed Hopper

The robust feed hopper facilitates easy feeding of logs and large branches.

Download PDF-files

Find our informational materials here for online reading, printing, or downloading.

See a wood chipper in Action

NOTE:

The video shows a PC-2700-PEC being fed by crane.