Snow blower V-230

Presentation

The V-230 is one of our most proven snow blowers. It has been on the market for many years and is continuously developed and updated according to customers' changing wishes and requirements. V-230 is particularly effective in very cold environments where snow is light and porous.

The simple and robust design of the hopper, which feeds the light snow into the fan, provides a high working speed and thus helps to keep roads open during heavy snowfall and the formation of snow drifts. This is where the saying "small and fast is better than big and lazy" really comes into its own. The simple construction means the model is sold at a very reasonable price.

Simple and robust features

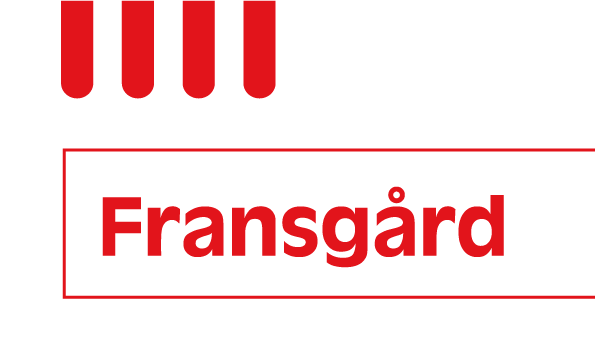

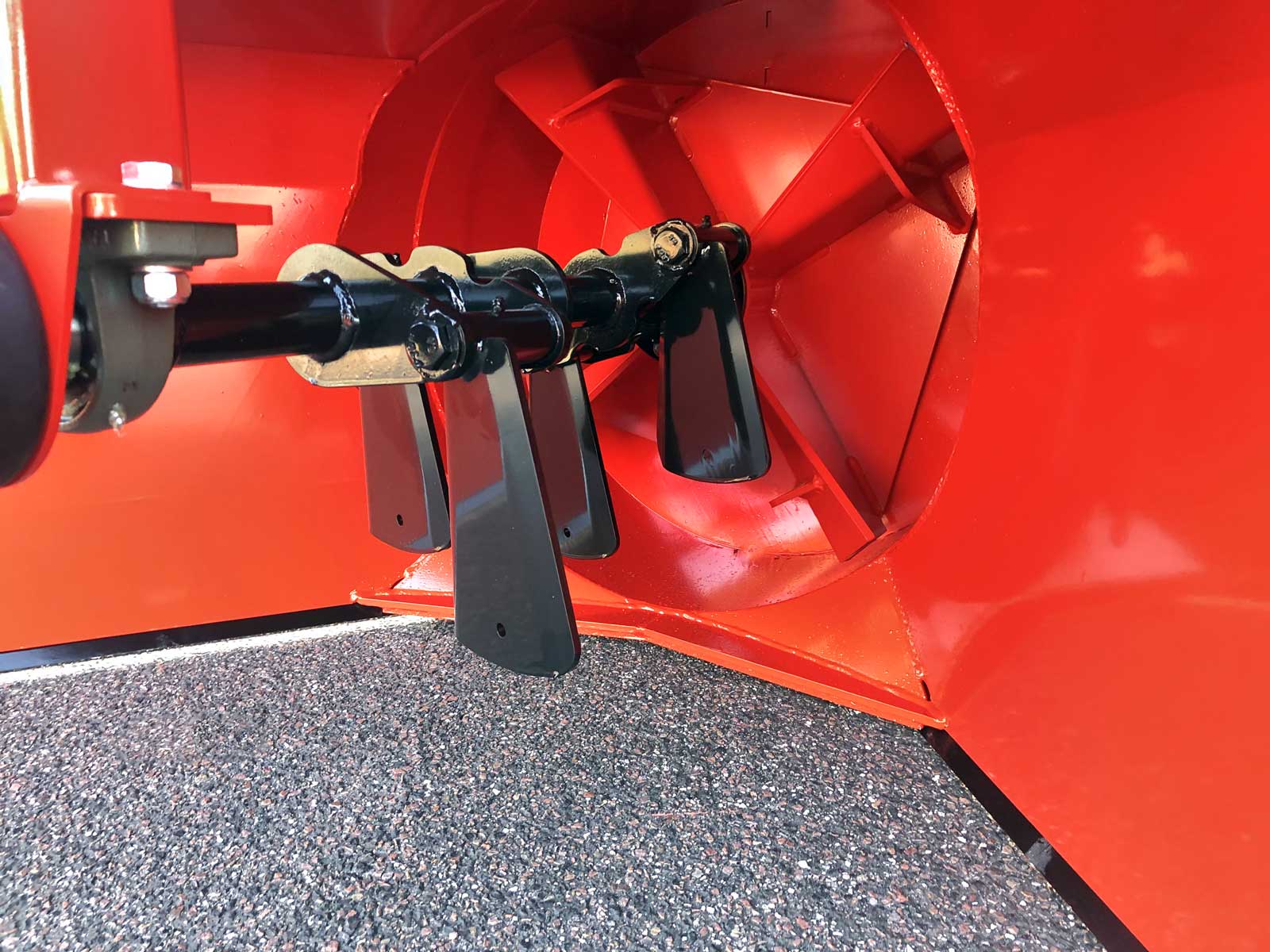

The V-230 is designed with 4 seperate feed blades and a heavy duty main axle with 1¾" PTO, providing high power.

Hydraulic 360° rotating spout as standard has a centre flap with greasable bolts, ensuring minimum wear on the top flap. Wear shoes and wear steel are made of Hardox 500 and are thus of an absolutely top quality.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Technical data:

| Model: | V-230 |

|---|---|

| Working width | 220 cm |

| Working width with edge blade Right | +10 cm |

| Ejector fan diameter | 72 cm |

| Ejector fan housing diameter | 24 cm |

| Number of feed blades | 4 |

| Spout hydraulic rotatable | 360° |

| Centre flap | Std. |

| Hydraulic top flap | Possible |

| 3-point suspension | Category II |

| PTO-pin | 1¾” |

| Power requirement | 45 HP |

| Push/front mounting | No |

| Weight | 450 kg |

Details:

3-point suspension

The fixed 3-point suspension is category II as standard

Bolt in the top flap

All S models are fitted with greasable bolts in the centre and top flaps to minimise vibration and extend life.

PTO bracket

The snow blowers are fitted as standard with a bracket for the PTO axle when the machine is parked.

Turntable

All spouts are mounted on a greasable ball bearing turntable, which allows the spout to rotate 360 degrees easily and freely. The oil engine with a gear wheel is well protected on the snow blower.

Prepared for wear shoes

All snow blowers are prepared for the installation of a wear shoe kit. Optional extra (item no. 2235).

Main axle

The heavy duty main axle has a 1¾" 6 spline PTO connector and has 4 loose impactors fitted to crush lumps.

Main frame

Strong main frame shaped like a V and with a solid square profile all around.

Bearing cover

The bearing cover is made of square profile with a moulded greasable bearing housing.

Bearing house, rear

The moulded and greasable bearing housing is mounted with 4 bolts and is well protected behind a screen.

Lifting eye

The snow blowers have standard lifting eyes for transport or moving to summer storage.

Centre and top flap

All snow blowers have both centre and top flaps as standard. Which makes it possible to control the snow jet with great precision.

Safety grill, spout

The spout has a standard safety grill fitted to prevent accidental contact with the impeller.

Wear steel

Reversible plain/galvanised wear steel in special wear steel is standard. Also available with serrated wear steel on request.

Positioning bracket on the spout

Manual adjustment of centre and top flaps without using tools. Hydraulic adjustment is an optional extra (item no. 2227).

Toothed rim

The powerful toothed rim on the spout is driven by a gear wheel, which is fixed with Loctite on the oil engine and which is securely located under the guard. A very reliable solution.

Top flap

The top flap can be angled down so that snow can be thrown down between the tractor and the snow blower when passing a side road, for example.

Optional extras:

Item No. 1417102 PTO

PTO axle with 8 mm 8.8 springbolt.

Item No. 2227

Hydraulic cylinder for adjusting the top flap of the spout to quickly control where the snow is thrown.

Item No. 2205A

Edge blade for the right side which bolts on. The triangle ensures that the snow enters the machine. The working width is increased by 10 cm.

Item No. 2235

1 set of right/left wear shoes can be adjusted in height, relieving wear on the wear steel and ensuring that the machine stays at the desired height.

Download PDF files

See our information material here, where you can also read it online, print or download the file.