Swath Wilter SV-8300SE / SV-8300SE-CD

Presentation

The popular SV-2500SE Swath Wilter is used as the base structure for the double-unit SV-8300SE swath conditioner. The machine is built with a robust construction and features hydraulic folding, making it both efficient and flexible—even during transport.

It is a towed model designed to process 2 swaths simultaneously, thus expanding the range of swath conditioners. Fransgård is the market leader in these machines.

The SV-8300SE Swath Wilter is equipped with 2 hydraulic side elevators. It can be used advantageously in both grass, hay, or straw and leaves a high airy swath without impurities such as soil and stones.

In short: BETTER CROP QUALITY.

Effective Double Swath Wilter with Multiple Adjustment Options

The SV-8300SE/SV-8300SE-CD Swath Wilter features two powerful rotors, each with 6 rows of springs spaced evenly around the shield, providing a consistent flow. Two sets of 4 V-belts or chain drives (optional) ensure optimal operation without interruptions.

With the side elevator, the swath can be moved to the side and adjusted in 3 positions. The best result is achieved when the material hits the center of the elevator. For large amounts of material, the belt can be lifted completely, and swath screens (optional) can be mounted.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Technical data

| Model: | SV-8300SE | SV-8300SE-CD |

|---|---|---|

| Working Width | 760-830 cm | 760-830 cm |

| Transport Width | 300 cm | 300 cm |

| Number of Rotors | 2 pcs | 2 pcs |

| Rotor Diameter | 80 cm | 80 cm |

| Rotor Speed at 540 RPM | 485 RPM | 485 RPM |

| Number of Raking Springs | 144 pcs | 144 pcs |

| Number of Wheels on Rotor | 4 pcs | 4 pcs |

| Number of Transport Wheels | 2 pcs | 2 pcs |

| Hydraulic Connections | 1 double + 1 single | 1 double + 1 single |

| 3-Point Hitch | Cat II | Cat II |

| PTO Output RPM | 400-540 | 400-540 |

| Power Requirement (kW) | Min. 40 kW | Min. 40 kW |

| Working Speed (km/h) | 10-22 | 10-22 |

| Weight | 3290 kg | 3290 kg |

| Transport Height | 400 cm | 400 cm |

| Transport Length | 540 cm | 540 cm |

| Lift Bracket | Cat II/III | Cat II/III |

Details

3-Point Hitch:

Det fleksible 3-punkt ophæng er valset i profilrør. Det fungerer samtidigt som trækbom af den bugserede maskine og sikrer, at maskinen følger terrænet bedst muligt.

Rear Wheels:

Two large rear wheels provide optimal transport of the machine and help with stable operation.

Rear Shield:

The curved plastic shield on the belt station ensures that the material quickly and easily falls onto the belt and is transported to the side.

Liftable Belt Station:

The belt stations can be hydraulically lifted so the material can pass directly through the machine. Swath screens can also be mounted to gather the swath (optional). These must be removed before the belt is folded down, and the machine is set for transport.

Belt Station:

Both rotors are equipped with a hydraulically driven belt that can move the material to either the right or left side.

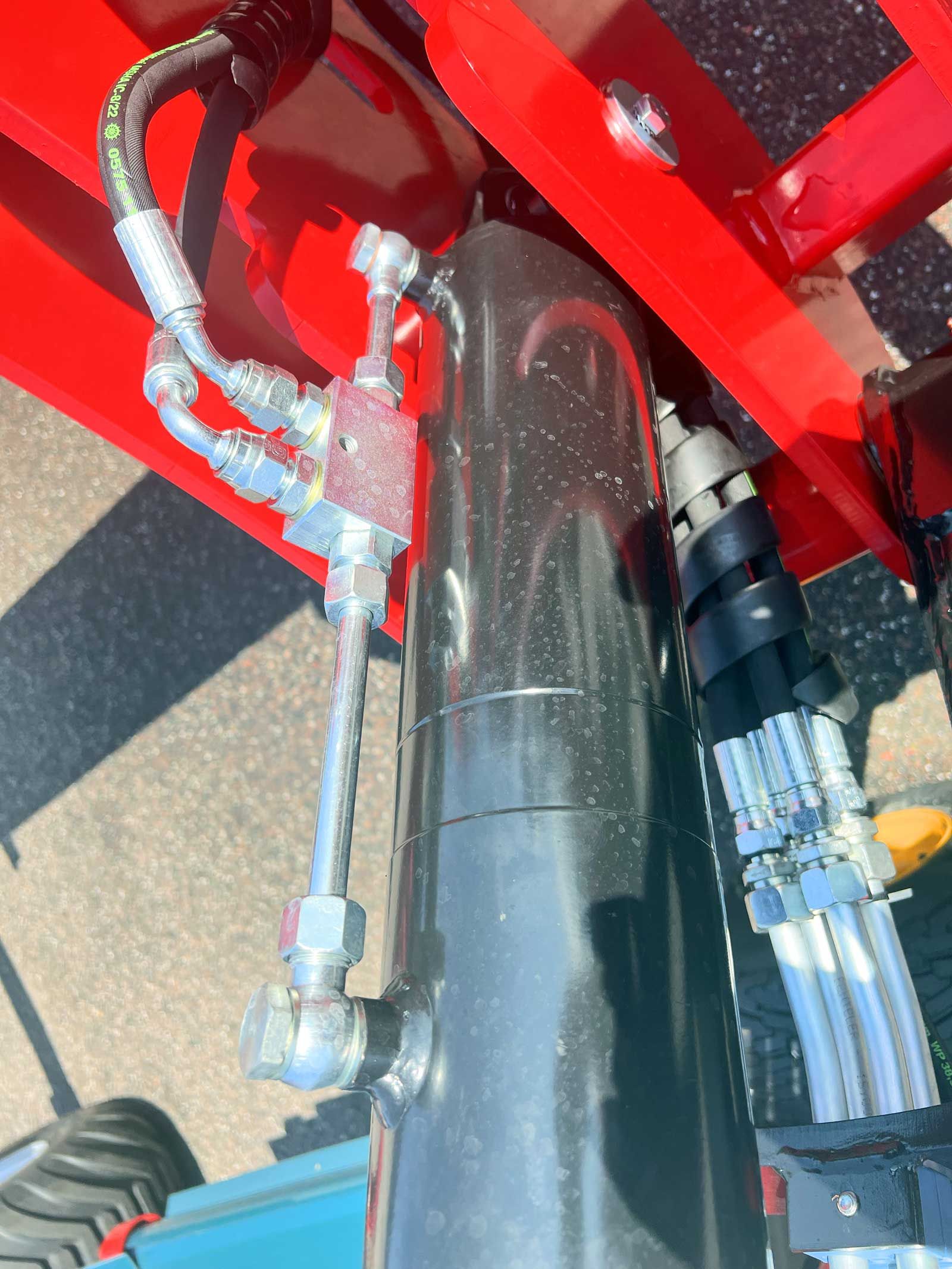

Rear Wheel Cylinder:

A powerful hydraulic cylinder with a lock valve ensures the machine is set in the optimal position both in operation and during transport.

Rotor Cylinder:

Very powerful cylinders lift and unfold the rotors for transport and working positions.

Pivot Joint on 3-Point Hitch:

The pivot joint with an outer limit on the 3-point hitch ensures that the machine follows the terrain optimally.

Electrical Control:

The small box with toggle switches provides easy and straightforward control of the machine's hydraulics.

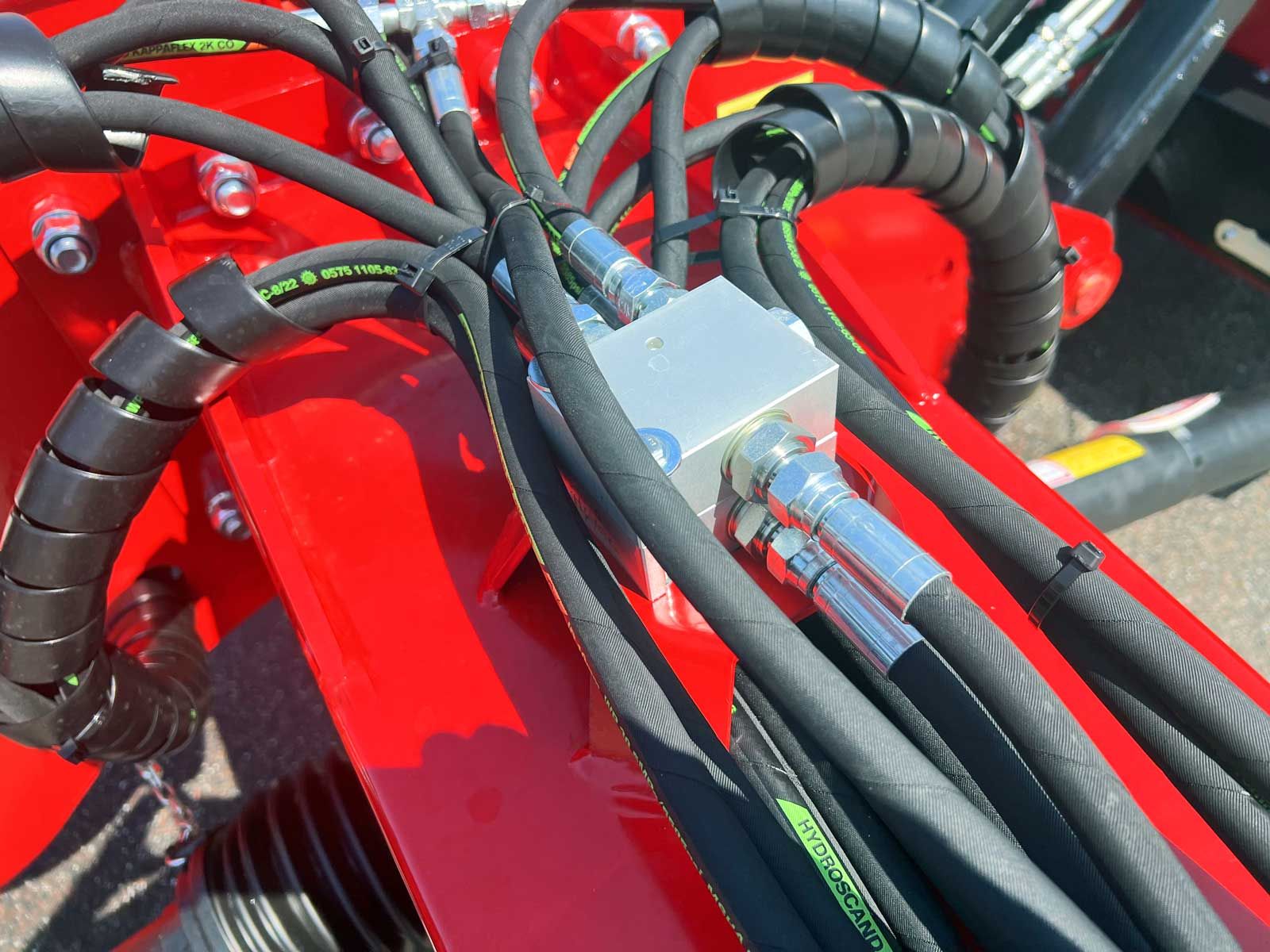

Distribution Valve:

The valve ensures the oil is distributed so that the rotors lift and lower simultaneously, and the machine follows the terrain optimally.

Gearbox, 3-Point:

The very robust swivel gearbox contributes to the reliability of the rotors and ensures the machine is towed optimally after the tractor.

Rubber Blocks:

Solid rubber blocks on the machine ensure smooth folding and transport of the machine in the transport position.

Rotor Wheels:

The two wide wheels on each rotor provide stable and smooth operation in the field. The wheels can be height-adjusted independently.

Main Frame:

The very solid main frame ensures stability and long service life of the machine.

Hydraulic Cylinder Belt:

Two hydraulic cylinders on each rotor provide quick lifting of the hydraulic belts, allowing material to pass directly through the rotors.

Hydraulic Control:

The compact hydraulic block and control box are well protected on top of the machine.

Hydraulic Rotor Adjustment:

Each rotor, suspended on two robust pipes, can be side-shifted via the hydraulic cylinder.

Rotor Housing:

The rotor housing is built on the same principle as our popular SV-2500SE. A solid construction.

Lock Valve, Rotor:

The lock valve on the hydraulic cylinder ensures the rotors remain in the set positions.

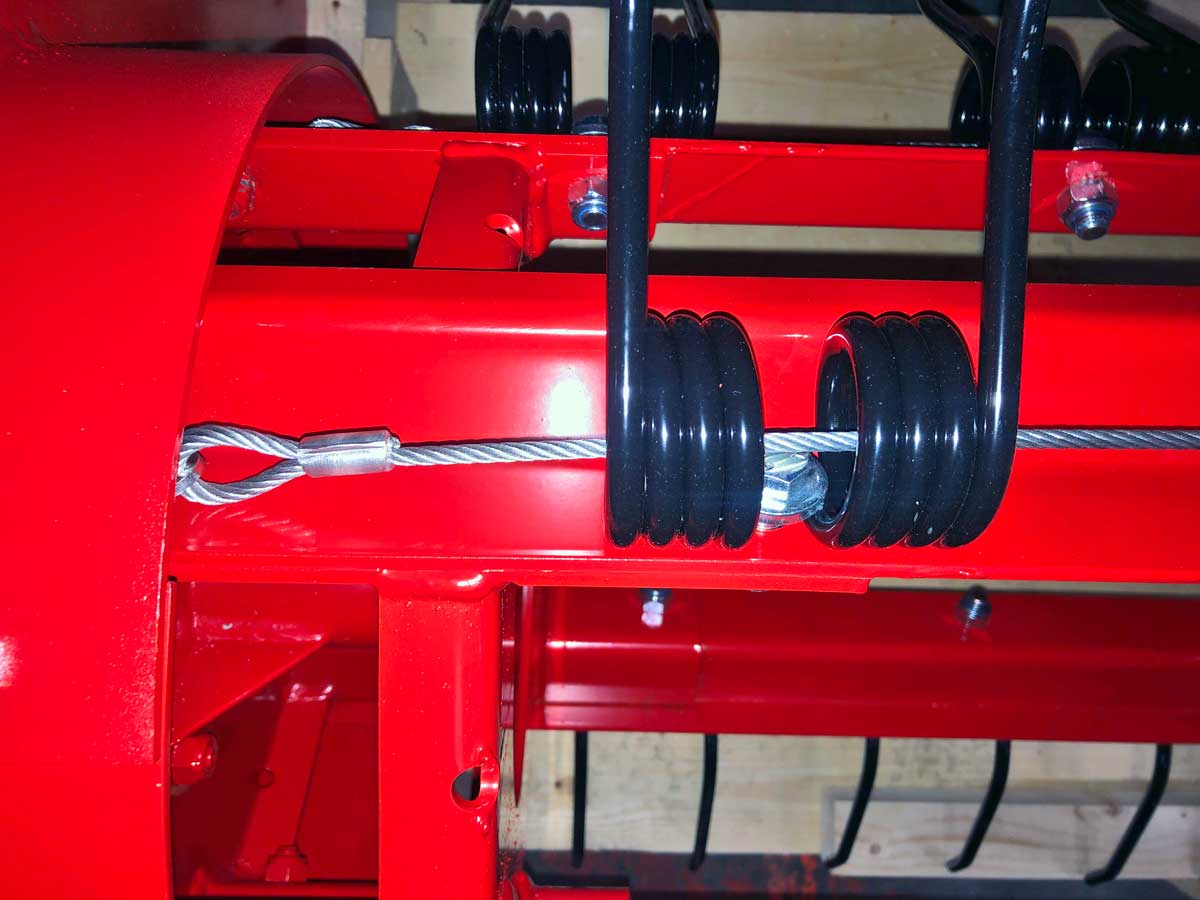

Brass Bushings:

The pivot joints on the machine are equipped with brass bushings to ensure long life and lower operating costs.

Oil Motor:

A 40cc oil motor with a valve ensures optimal operation of the belt station and allows the belt to run both ways.

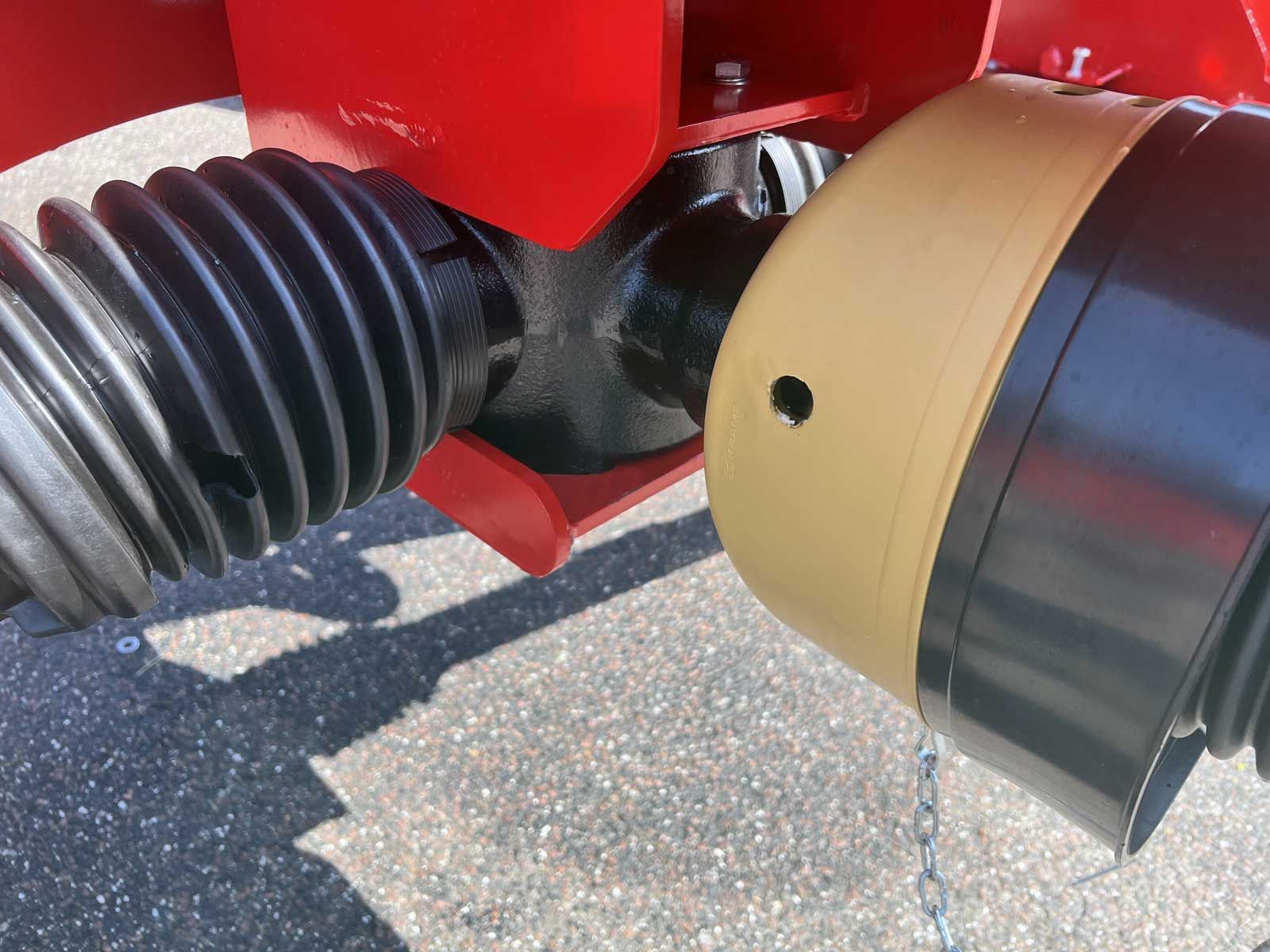

PTO Rotor:

The PTO shaft with Rilsan pipe ensures reliability and allows the rotors to be side-shifted during operation.

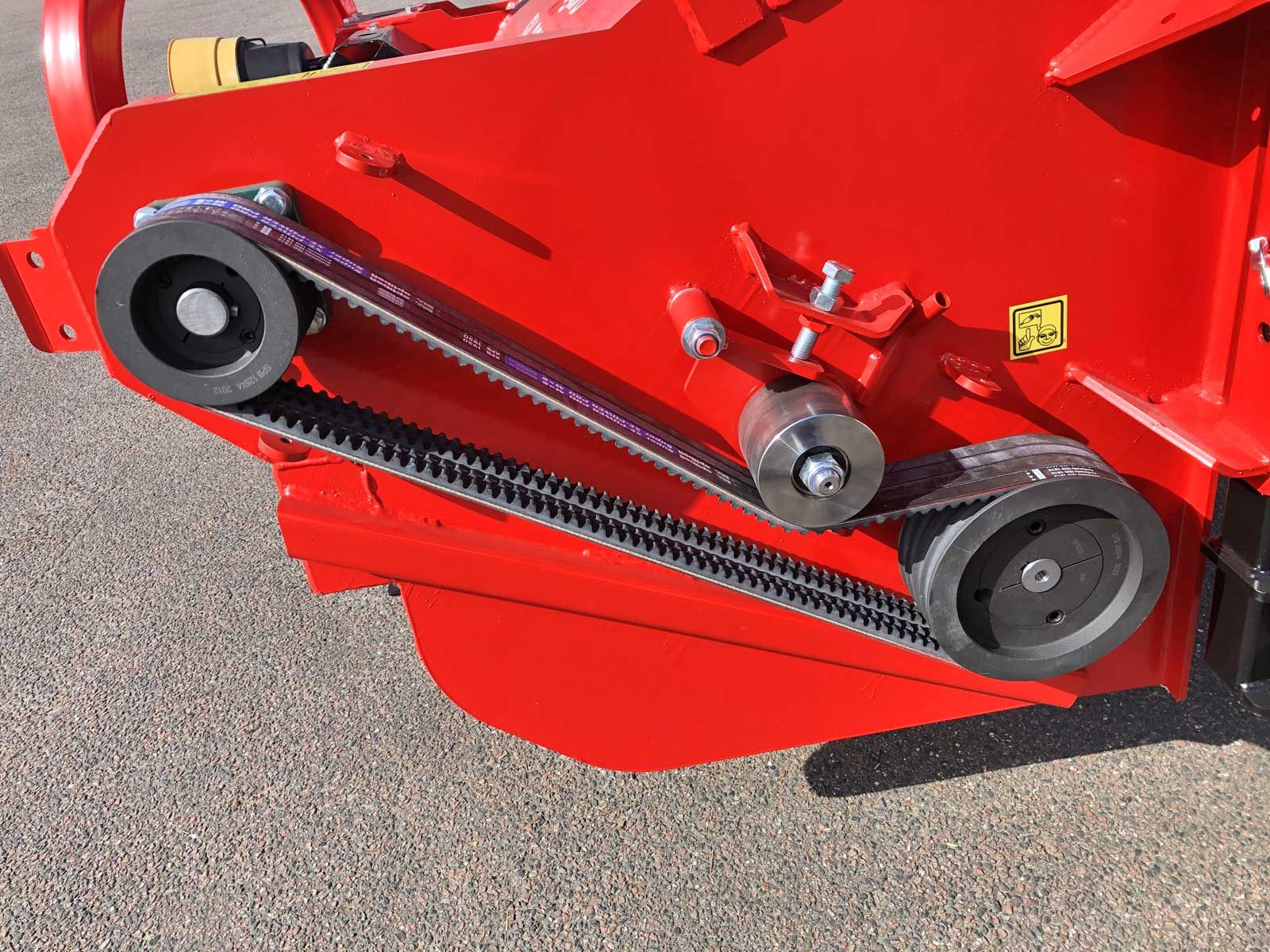

Rotor Belt Shield:

The belt shield with service hatch and external belt tensioning.

Lubricable Pivot Joints:

All pivot joints are lubricable and equipped with grease nipples.

Support Leg:

The robust support leg folds up during work and ensures stable parking of the machine.

T-Gearbox:

The T-gearbox is well protected inside the machine and ensures even operation of the rotors.

Transport:

The machine folds hydraulically for transport, providing a transport width of 3 meters.

Transport Height:

When the rotors are lowered via hydraulics, the transport height is under 4 meters.

V-Belts:

The 4 XPB V-belts are tensioned via the large tensioning wheel for optimal operation. The position of the tensioning wheel helps achieve even greater belt drive efficiency.

Belt Carriers:

The robust elevator belt is equipped with 15 pcs. 35 mm high carriers, spaced 400 mm apart, providing efficient material transport.

Rotor Reinforcement:

The rotor on the machine is equipped with 10 internal reinforcements.

Rotor Interior:

The 72 closely spaced pickup springs have a slight bend at the end and maintain the same distance to the shield all the way around, ensuring optimal flow through the machine and a perfect swath.

Rotor:

The strongest rotor on the market has 6 rows of springs and a diameter of 80 cm. The spring rows can be replaced individually. The same applies to the 72 springs.

Rotor Shield:

Wide and closely spaced shields around the ends of the rotor ensure that the material does not wrap around the ends.

Exterior Shield:

The shield at the bottom of the cover can be removed to achieve a 10 cm larger entrance to the machine, which is a great advantage when working with larger material amounts.

Lights and Reflectors:

The machine is equipped as standard with a reflector plate, LED light with triangle, and marker lights with white, yellow, and red lights.

Optional Accessories

Item No. 4236

Tooth protection consisting of 6 pcs. 5 mm galvanized wires with brackets. Ensures that broken springs do not fall into the swath. Can be retrofitted.

Item No. 4617:

Hydraulic hose for free return to the tank from the oil motor on the side elevator.

Item No. 4612 / 4615

Swath screen set for mounting on the machine when the side elevator is folded up. Must be removed before the side elevator can be lowered again, and the machine can be folded for transport. 4612 is 85 cm long, and 4615 is 125 cm long.

Item No. 4616

Short swath screens that can remain on the machine when the belt stations are folded down, and the machine can be folded for transport.

Download PDF-files

See our information material here, where you can also read it online, print it, or download the file.